Coal plough machine

A coal plow and coal plow board technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient installation and maintenance, complex structure, etc., and achieve the effect of easy installation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below.

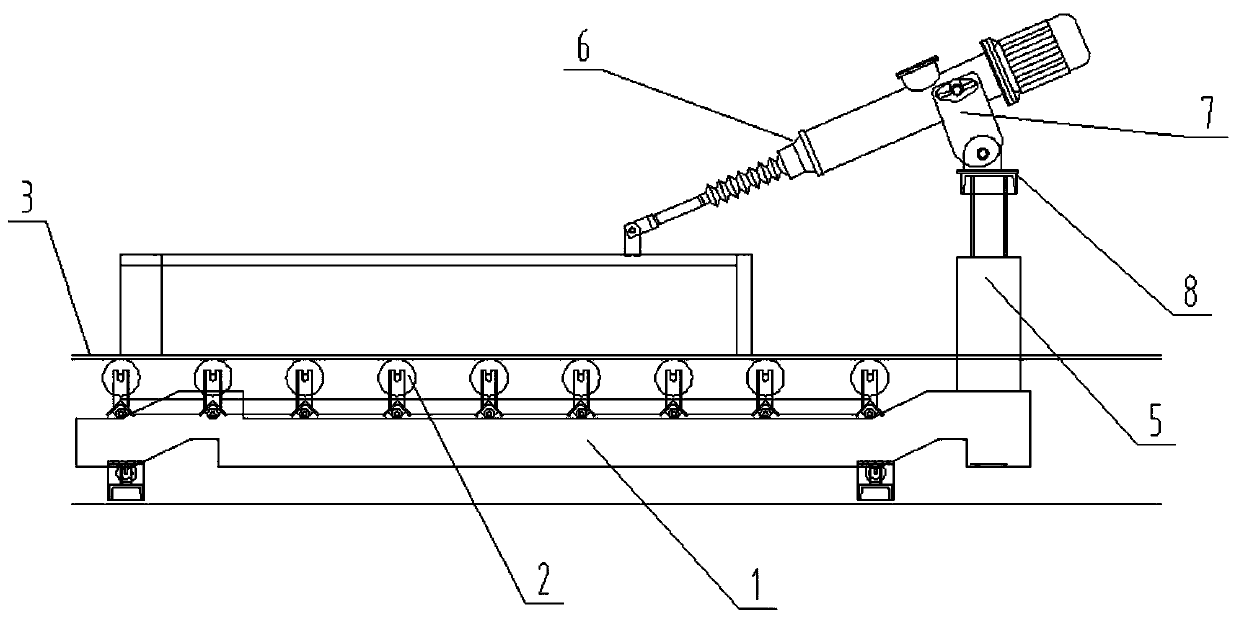

[0014] Such as figure 1 As shown, a coal plow includes a support 1, a coal plow plate 4, a pair of vertically arranged lifting hydraulic cylinders 5, a linear electric push rod 6, multiple sets of supporting rollers 2 arranged on the upper part of the support 1, and multiple sets of supporting rollers. The upper surface of the roller 2 is provided with a belt 3;

[0015] The coal plow plate 4 is composed of coulters arranged symmetrically on both sides and integrally formed;

[0016] A pair of vertical lifting hydraulic cylinders 5 are respectively arranged on the front and rear sides of the belt 3, the cylinder barrels of a pair of vertical lifting hydraulic cylinders 5 are fixedly connected with the support 1, and a pair of vertical lifting hydraulic cylinders 5 The piston rod end of the piston rod is fixedly connected with a crossbeam 8 arranged horizontally;

[0017] The seat body of the linear electric pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com