Preparation method of ramelteon impurity

A technology for ramelteon and impurities, which is applied in the field of preparation of ramelteon impurities, and can solve problems such as the inability to synthesize monodebrominated products in a directional manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

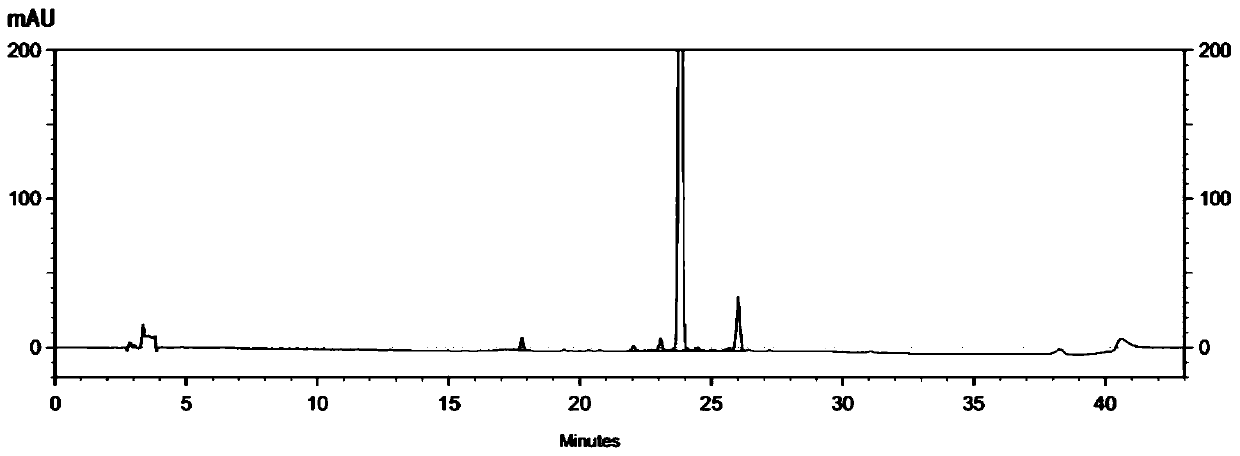

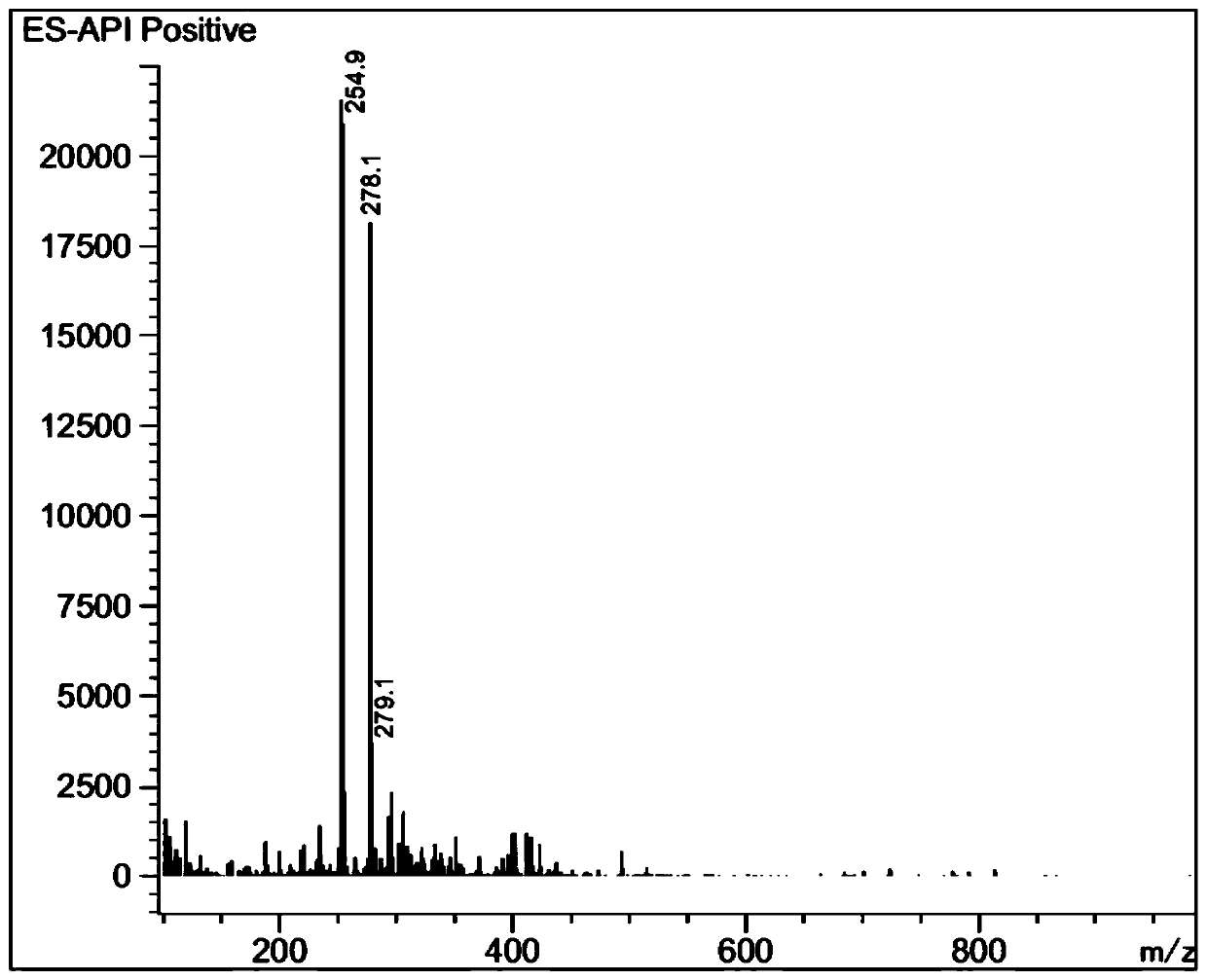

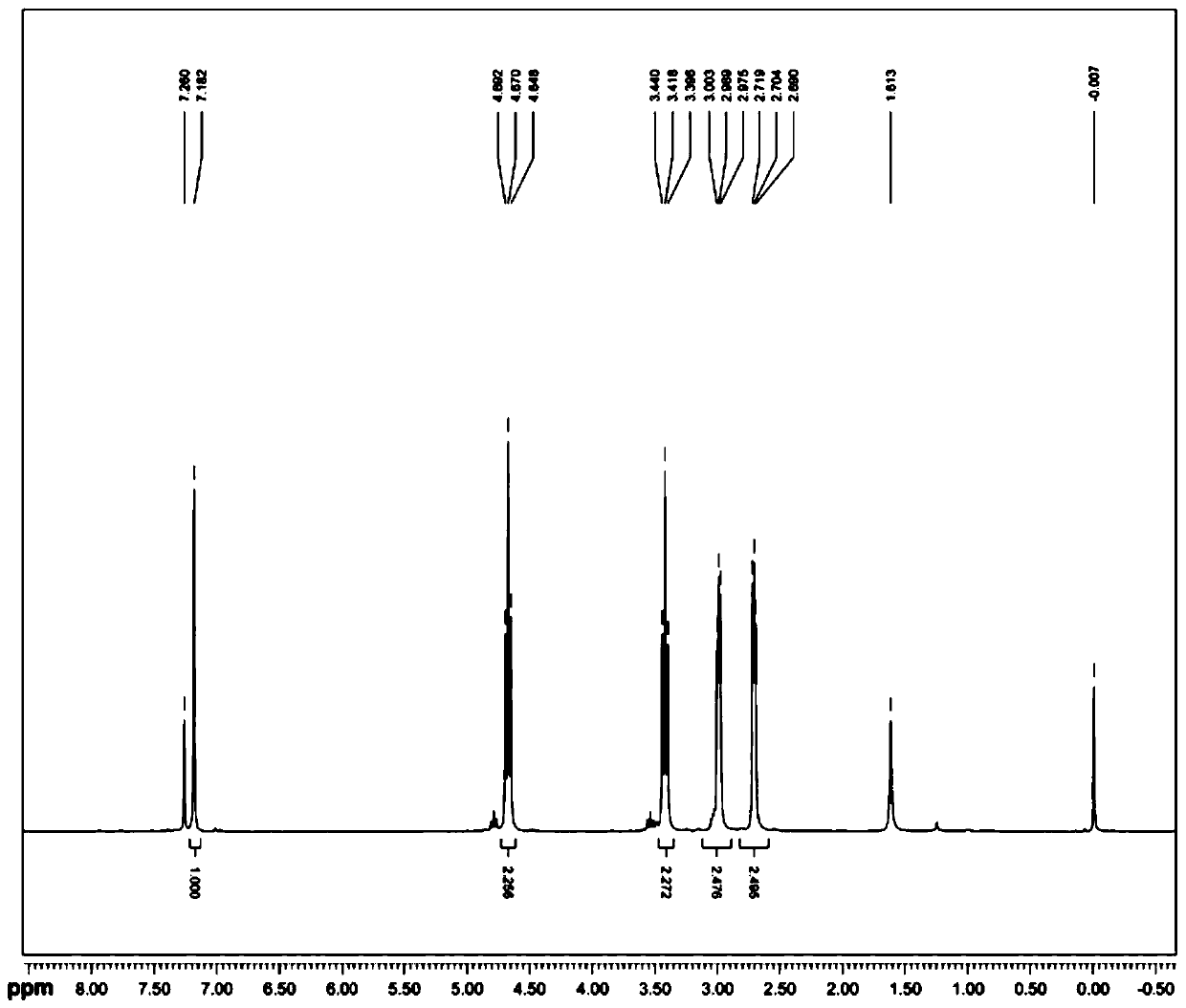

Image

Examples

Embodiment 1

[0030] A kind of preparation method of ramelteon impurity, concrete preparation steps are as follows:

[0031] (1) In terms of compound I, take 10.00g of compound I, put it in a reaction flask, add 60g of dichloromethane and 0.04g of N,N-dimethylformamide, stir to dissolve, and protect with nitrogen; control the temperature of the reaction solution at 20~30℃, add 4.76g of oxalyl chloride dropwise; keep the temperature for 1h after the dropwise addition; reduce the temperature of the reaction solution to -5~0℃, add 4.76g of aluminum trichloride in 4 batches, and react at 0~5℃ after the addition is completed 1h, the reaction was monitored by TLC; after the reaction, 40g of absolute ethanol A was added to quench the reaction at a temperature of 0-10°C. After the addition, the reaction was stirred at 0-15°C for 2h, filtered, and the filter cake was slurried with 40g of anhydrous ethanol B. After drying, 7.73 g of compound II was obtained with a yield of 81.5%.

[0032] (2) In ter...

Embodiment 2

[0044] A kind of preparation method of ramelteon impurity, concrete preparation steps are as follows:

[0045] (1) In terms of compound I, take 126.0g of compound I, put it in a reaction flask, add 800g of dichloromethane and 0.5g of N,N-dimethylformamide, stir to dissolve it, and protect it with nitrogen; control the temperature of the reaction solution at 20~30℃, add 60.0g of oxalyl chloride dropwise; keep the temperature for 1h after the dropwise addition is completed; reduce the temperature of the reaction solution to -5~0℃, add 60.0g of aluminum trichloride in 6 batches, 10.0g each time, after the addition is completed React at 0~5℃ for 1h, and TLC monitors the reaction; after the reaction is over, add 500g of absolute ethanol A at a temperature of 0~10℃ to quench the reaction, stir at 0~15℃ for 2h after the addition, filter, filter cake with 500g Water ethanol B was slurried and dried to obtain 102.4 g of compound II with a yield of 85.7%.

[0046](2) In terms of compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com