X52 pipeline steel hot-rolling coiled plate with super-thick specification and production method for same

A technology for pipeline steel and hot-rolled coil, applied in the direction of manufacturing converters, etc., can solve problems such as no method proposed, and achieve the effects of reducing production cost, improving strength and toughness, and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with embodiment:

[0031] A hot-rolled coil of ultra-thick specification X52 pipeline steel, the chemical composition in the steel contains: C0.060%-0.070%, Si 0.15%-0.25%, Mn 1.40%-1.50%, Nb 0.034%-0.050 %, Ti0.008%~0.022%, Cr 0.11%~0.17%, Al 0.015%~0.045%, P≤0.02%, S≤0.008%, N≤0.008%, and Pcm≤0.17%, the rest is Fe and not Avoid impurities.

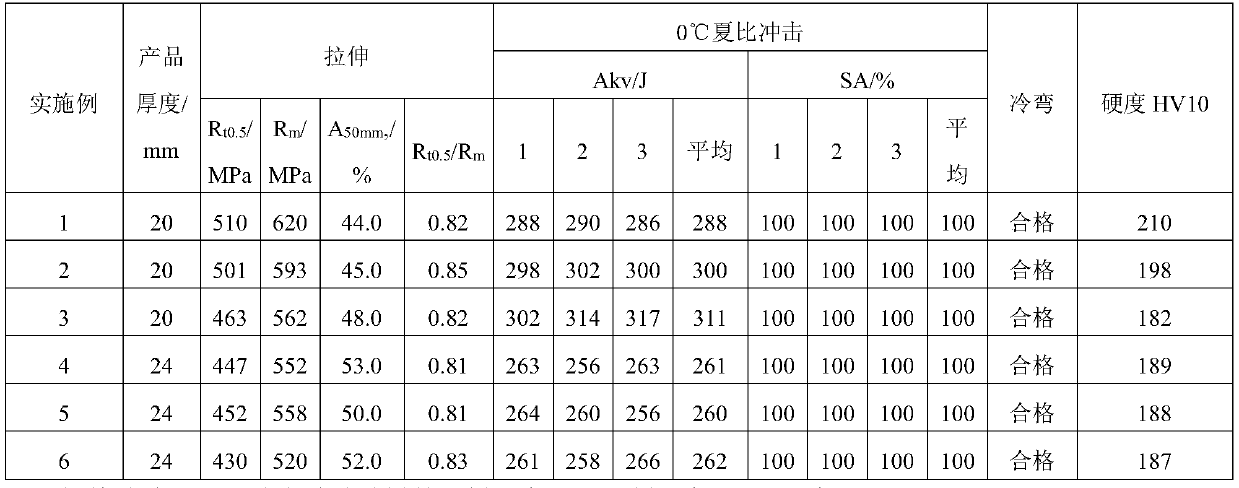

[0032] Coil yield strength R t0.5 430~510MPa, tensile strength R m 520~620MPa, elongation A50mm ≥44%, single-valued Charpy impact energy Akv≥256J at 0°C, hardness value ≤210HV10, uniform structure in the thickness direction of the product.

[0033] The thickness of the finished coil is ≥20mm.

[0034] A production method for hot-rolled coils of ultra-thick specification X52 pipeline steel, the production process involves: molten iron pretreatment - converter smelting - out-of-furnace refining (LF+calcium treatment) - continuous cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com