A reinforced concrete cylindrical node area steel wire mesh wrapped and external thin-walled circular steel pipe reinforcement structure and preparation method

A reinforced concrete and strengthening structure technology, applied in the direction of structural elements, building reinforcements, building components, etc., can solve the problems of "strong beams and weak columns, collapse of buildings and other problems, achieve good restraint, prevent early fall off, and improve stress performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

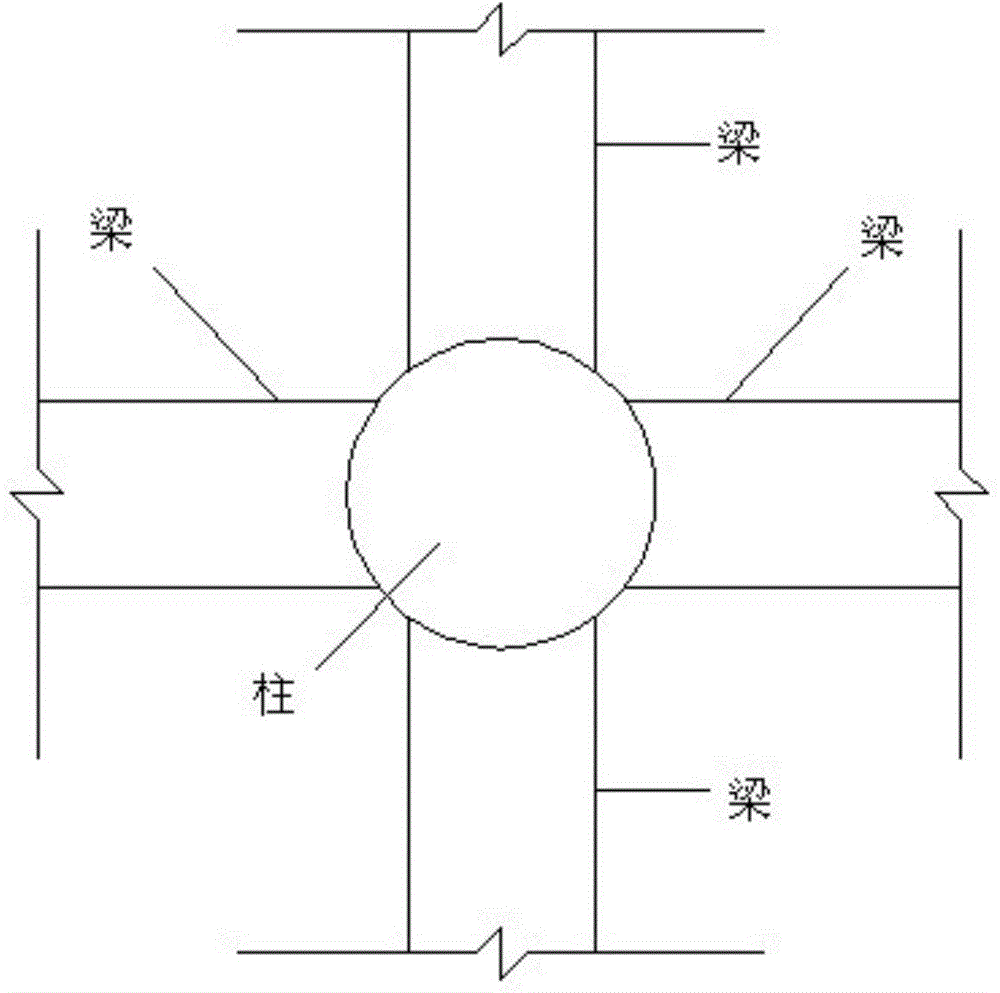

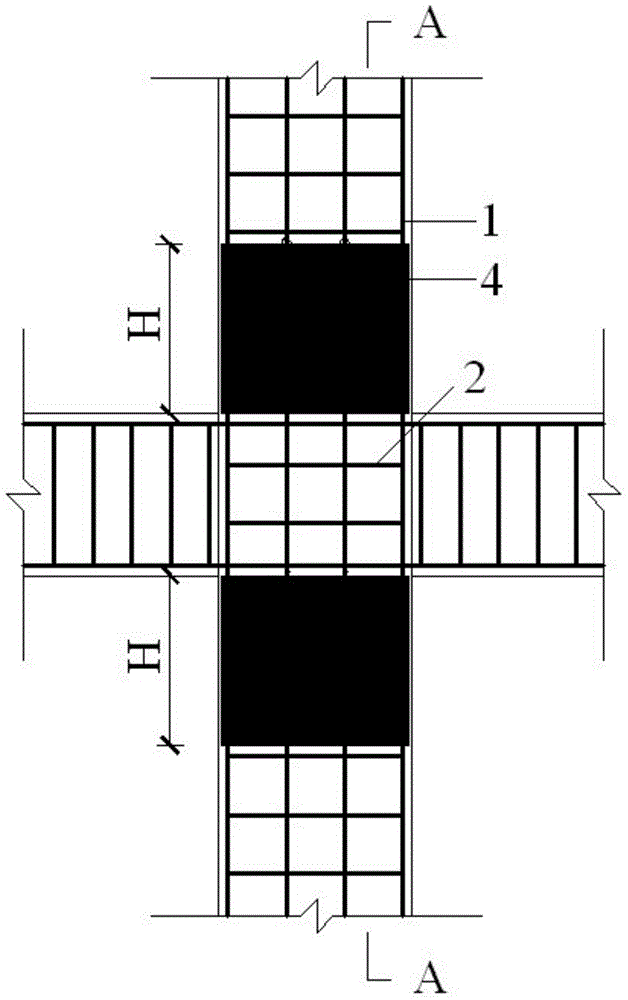

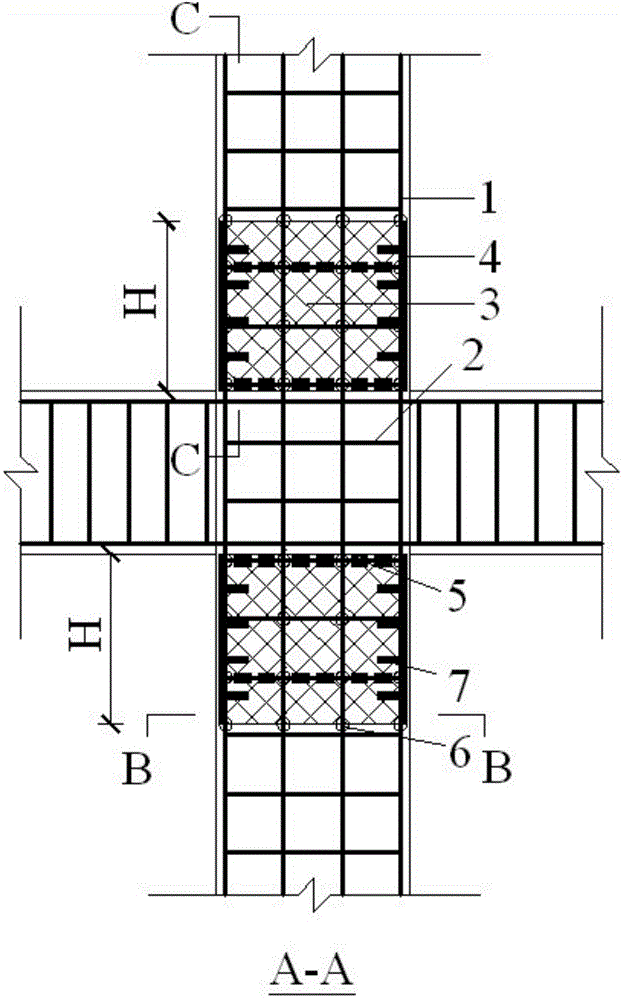

[0031] A reinforcement structure wrapped by steel mesh in the joint area of reinforced concrete cylinders and reinforced with thin-walled circular steel pipes, including a reinforcement cage, which is formed by binding and fixing the longitudinal reinforcement 1 and the stirrup 2 of the reinforced concrete cylinder; it is characterized in that it also includes a reinforcement structure consisting of Steel wire mesh 3, thin-walled round steel pipe 4, spacer block 5, binding wire 6 and nailing 7; the reinforcement structure refers to: at the upper end of the cylindrical joint, within the range of the height H of the upper edge of the beam section, and at the lower end of the cylindrical joint , within the range of the lower edge H of the beam section, the outsourcing steel wire mesh 3, H takes the larger value of 1.5D and 500mm, and D is the outer diameter of the reinforced concrete cylinder; for the upper part of the cylindrical node, the lower edge of the steel mesh and the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com