Fully sealed electric flapper valve

A fully-sealed, plug-in valve technology, used in sliding valves, valve details, valve devices, etc., can solve the problems that pneumatic plug-in valves cannot control the amount of material, fail to meet environmental protection requirements, and have poor sealing effects. To achieve good sealing, simple structure, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

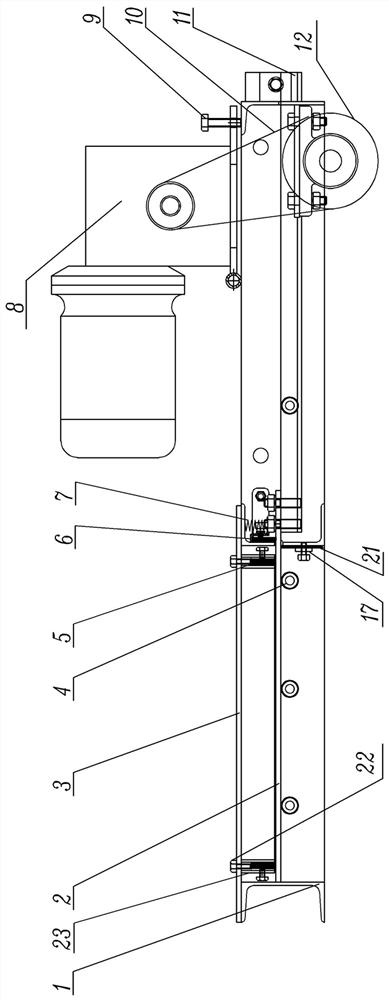

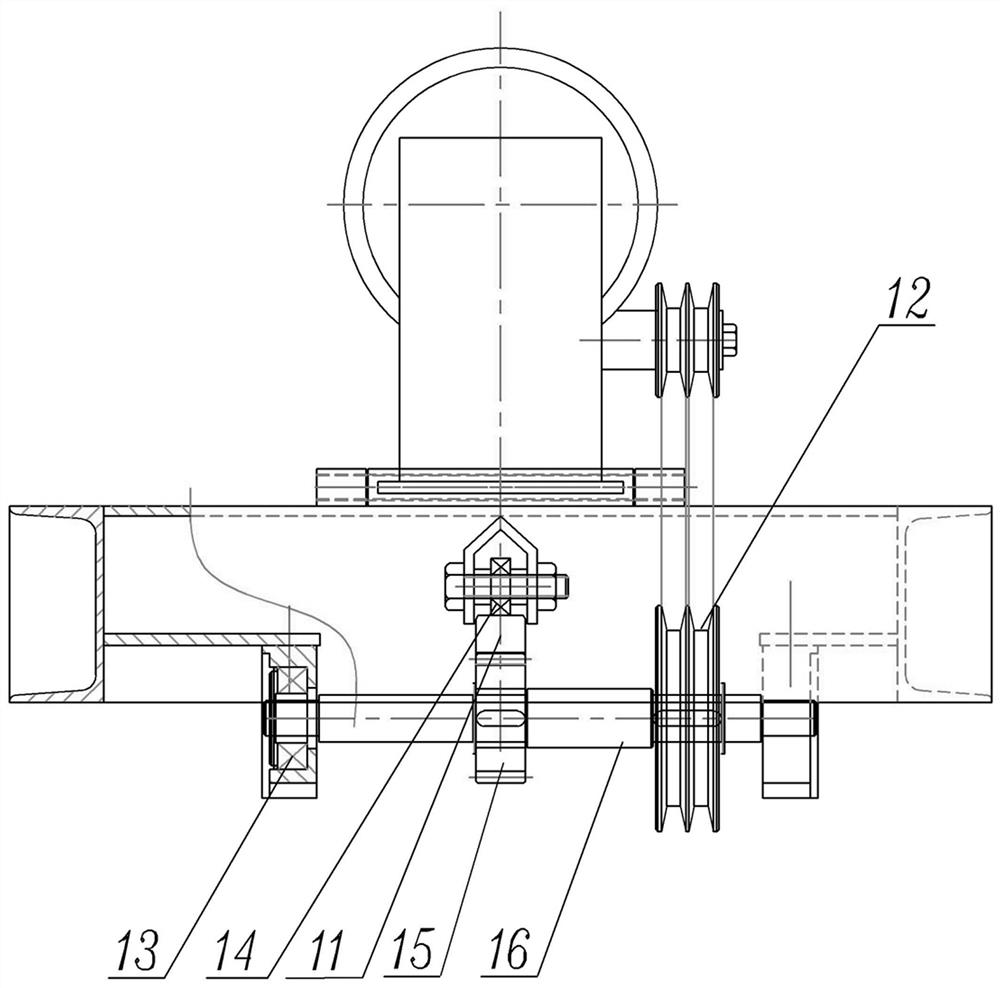

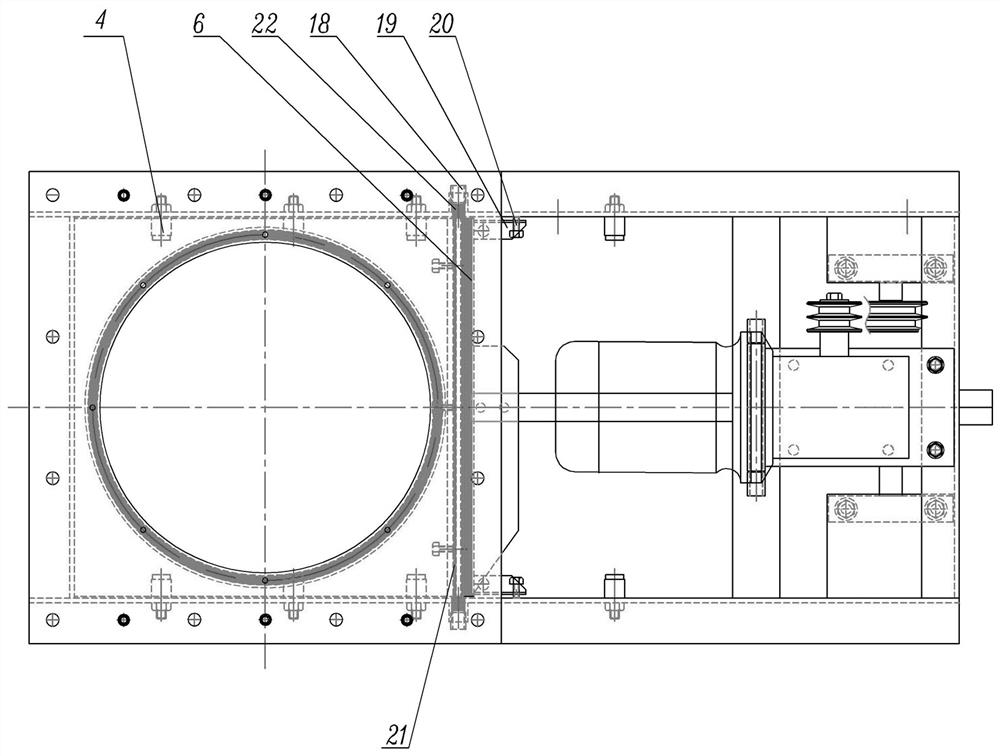

[0043] Below in conjunction with accompanying drawing, the present invention will be further described:

[0044] The fully-sealed electric flapper valve provides a fully-sealed electric flapper valve for powder or mixed material discharge control; it includes two parts: the valve body and the driving device. The driving device is a set of existing motor reducer driving device. The fully-sealed electric plug-in valve works reliably, is easy to install, has good sealing performance, and meets environmental protection requirements during use. The transmission structure of the gear and the rack with the teeth facing down avoids the wear of the gear and the rack by dust and improves the service life of the flapper valve. By adjusting the tension screw, you can easily adjust the tightness of the belt. The valve normally has two states of open and closed. The driving device and the valve body are connected by a triangle belt. The valve body includes an upper sealing body, an inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com