A barrel type composite insulating material insulation performance testing device

A technology of composite insulation and insulation performance, applied in the direction of measuring devices, measuring electricity, and testing ship construction, etc., can solve problems such as deterioration, insulation breakdown, and damage to insulation structures, and achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

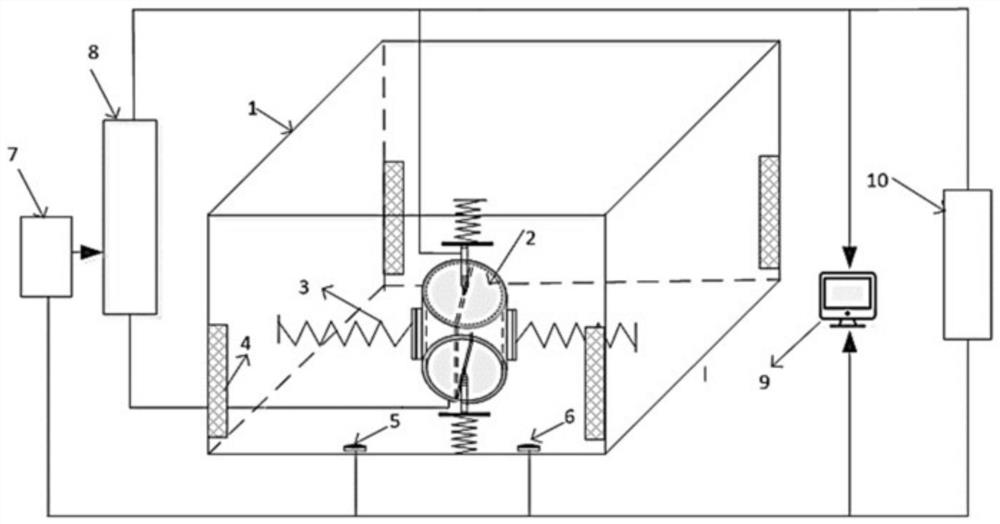

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Depend on figure 1 It can be seen that a barrel-type composite insulating material insulation performance testing device mainly includes a transparent thermostat 1, an electrode system 2, a support rod 3, a heating tube 4, a temperature sensor 5, a humidity sensor 6, a temperature control box 7, and an external power supply system 8 , computer 9, partial discharge detector or voltage measuring instrument 10. The operation method is as follows:

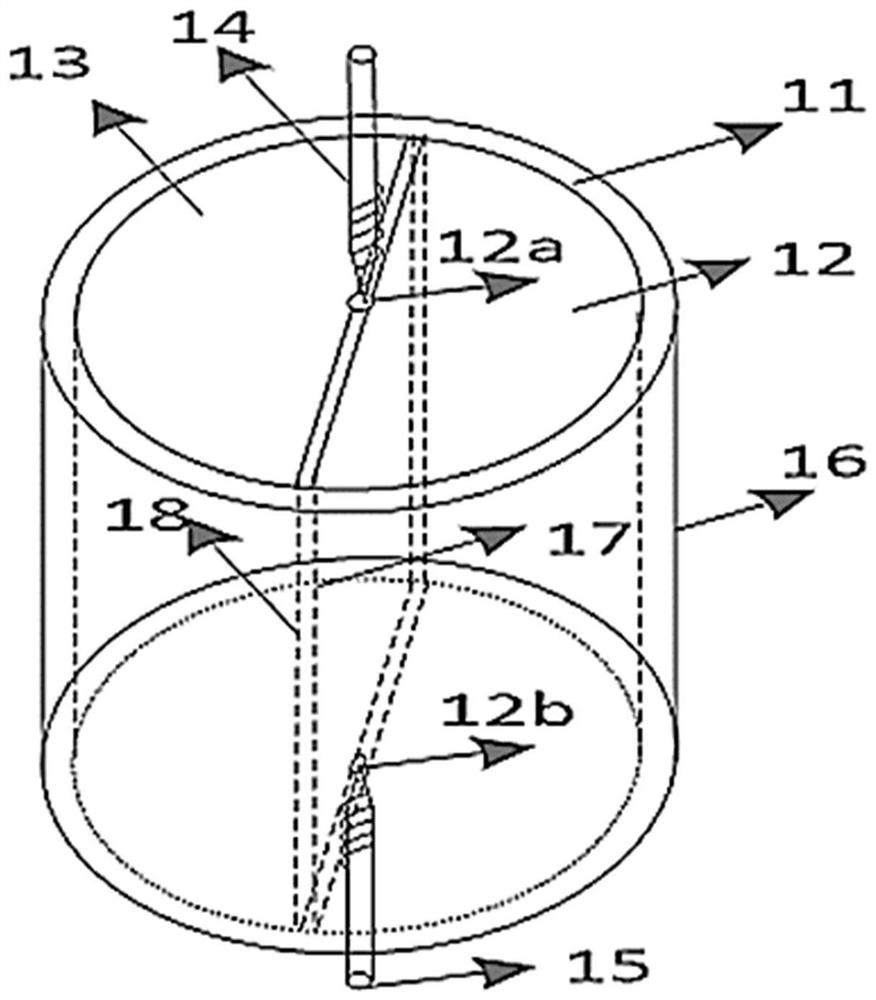

[0015] like figure 2 As shown, the electrode system 2 is composed of a high voltage electrode and a ground electrode. The high-voltage electrode adopts a cylindrical copper rod, the outer surface of which is polished smooth, the diameter is equal to the inner diameter of the cylindrical solid composite insulating material 11, and the height is smaller than the height of the insulating materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com