Warehouse navigation intelligent vehicle scheduling method based on global vision

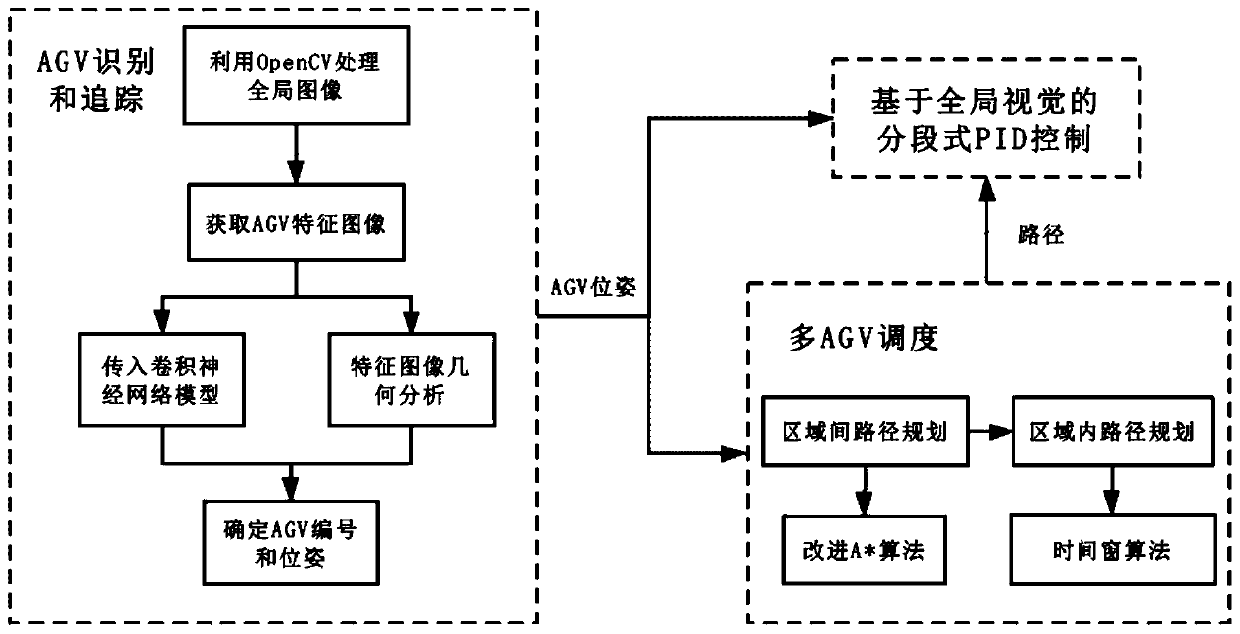

A scheduling method and intelligent vehicle technology, applied in two-dimensional position/channel control, vehicle position/route/height control, control/adjustment system, etc., can solve the problem of high difficulty in storage system configuration, low control efficiency, and unfavorable overall planning And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following examples and drawings are combined to further describe the present invention in detail, but the embodiments of the present invention are not limited thereto.

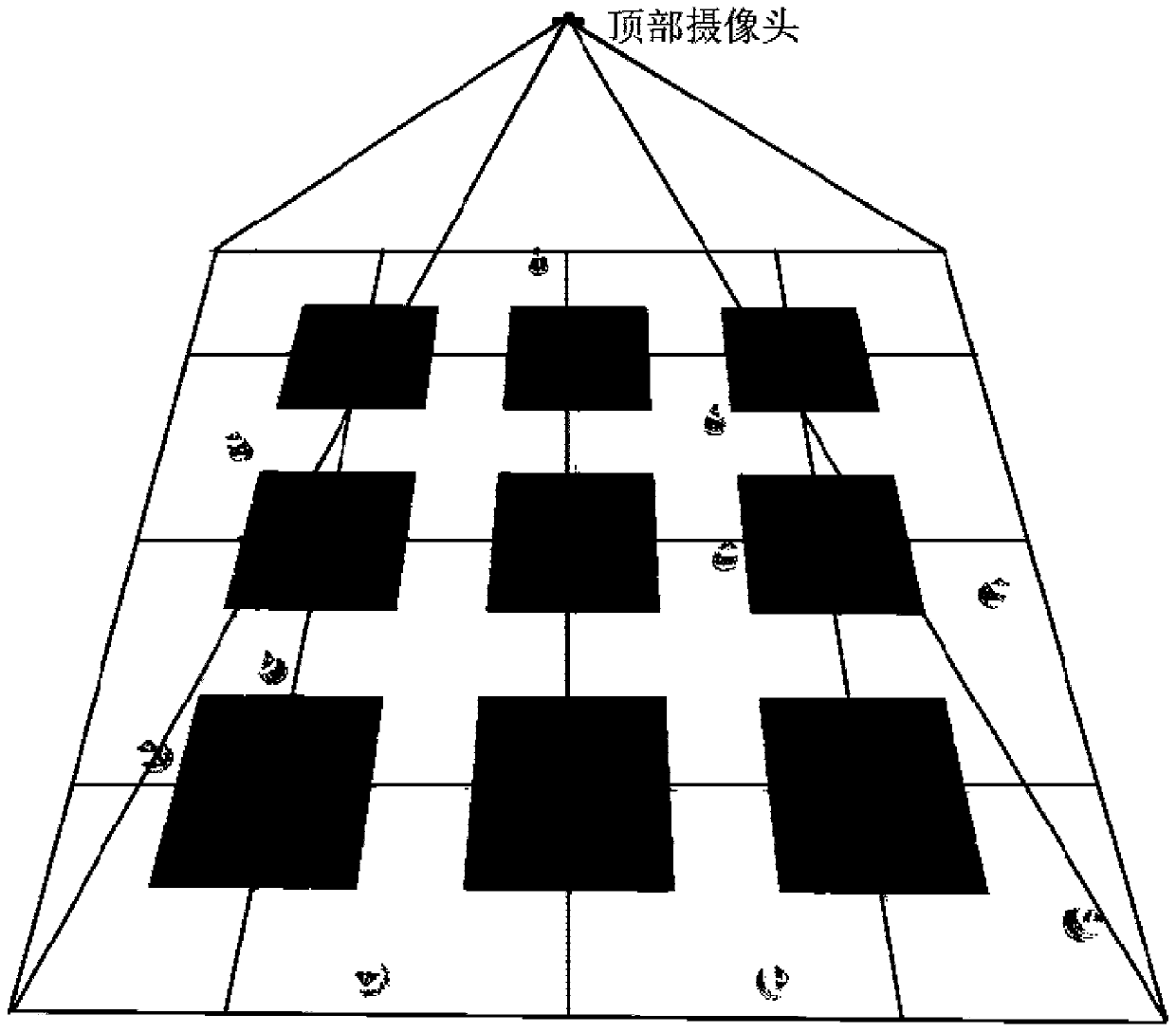

[0069] figure 1 As a storage system based on global vision, there are 10 storage navigation smart vehicles running in the warehouse on the Gazebo simulation platform. The top of the AGV is printed with a characteristic pattern containing numbers from 0 to 9. A camera is installed above the warehouse to obtain the global image of the warehouse. Then realize the identification and tracking of multiple AGVs.

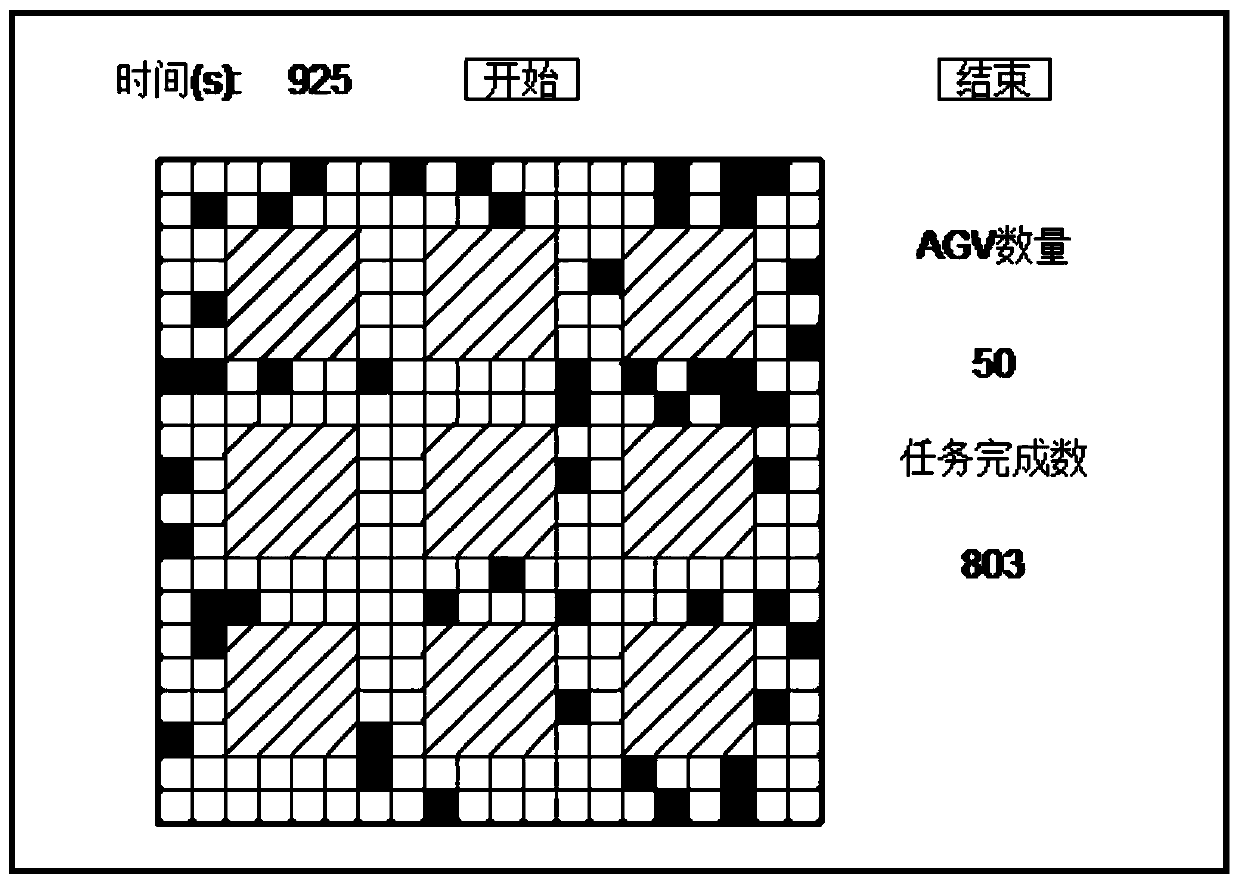

[0070] figure 2 For the multi-AGV scheduling part, use the MATLAB operation scheduling algorithm to control a total of 50 warehouse navigation smart vehicles including the above 10 AGVs. The black grid in the figure indicates the AGV, the white grid is the area where the AGV moves freely, and the shaded part is the obstacle. Areas where AGVs cannot pass through such as objects or shelves. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com