Rapid activation method for film electrode of proton exchange film fuel cell and application thereof

A fuel cell membrane and proton exchange membrane technology, applied in the disposal/recycling of fuel cells, fuel cells, battery recycling, etc., can solve the problem of long activation time and achieve the effect of improving activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

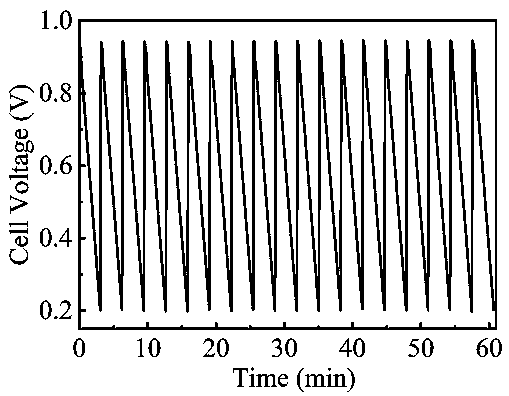

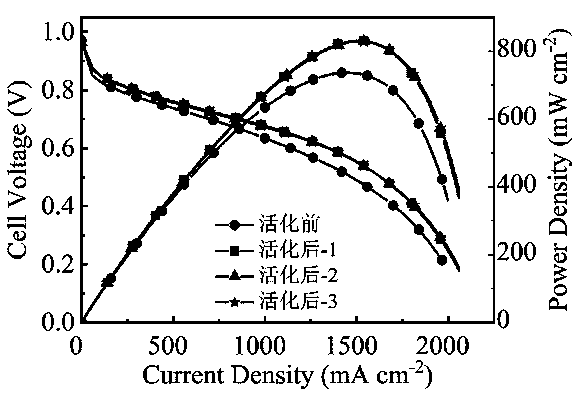

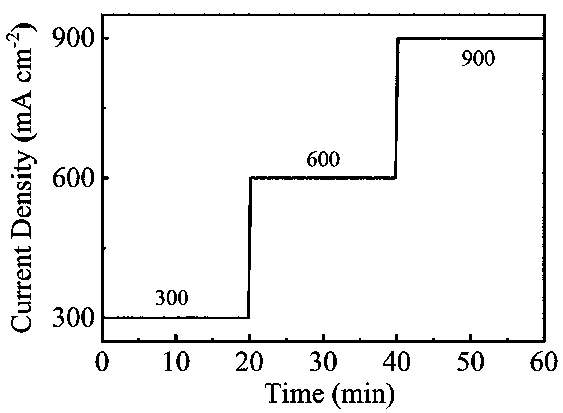

[0022] Make the active area 5 cm 2 The membrane electrode is assembled into the single cell fixture and connected to the test instrument. After checking the airtightness of the fixture, N is introduced into the cathode and anode. 2 Purge for 30 s. The working temperature was set at 80 °C, and air and hydrogen with a relative humidity of 100% were fed to the cathode and anode respectively, the stoichiometric ratio was 1.5, and the gas pressure was set to 0.1 MPa. After the temperature rose to 80 °C, the fuel cell was forced to activate with a constant rate of continuously variable voltage. The activation procedure was as follows: the voltage was increased from the open circuit voltage to 4 mV s -1 The constant rate linearly decreases to the preset low voltage value of 0.2 V. When the voltage of the single cell drops to 0.2 V, the current is quickly cut off, and the battery returns to the open circuit voltage ( figure 1 ). The above activation steps were repeated, and the pol...

Embodiment 2

[0024] Make the active area 5 cm 2 The membrane electrode is assembled into the single cell fixture and connected to the test instrument. After checking the airtightness of the fixture, N is introduced into the cathode and anode. 2 Purge for 30 s. The working temperature was set at 80 °C, and air and hydrogen with a relative humidity of 100% were fed to the cathode and anode respectively, the stoichiometric ratio was 1.5, and the working pressure of the gas was set to 0.1 MPa. After the temperature rose to 80 °C, the fuel cell was forced to activate with a constant rate of continuously variable voltage. The activation procedure was: the voltage was increased from the open circuit voltage to 10 mV s -1 The constant rate linearly decreases to a preset low voltage value of 0.2 V. When the cell voltage drops to 0.2 V, the current is quickly cut off, and the battery returns to the open circuit voltage. The above activation steps were repeated, and the polarization curve and power...

Embodiment 3

[0026] Make the active area 5 cm 2 The membrane electrode is assembled into the single cell fixture and connected to the test instrument. After checking the airtightness of the fixture, N is introduced into the cathode and anode. 2 Purge for 30 s. The working temperature was set at 80 °C, and air and hydrogen with a relative humidity of 100% were fed to the cathode and anode respectively, the stoichiometric ratio was 1.5, and the working pressure of the gas was set to 0.1 Mpa. After the temperature rose to 80 °C, the fuel cell was forced to activate with a constant rate of continuously variable voltage. The activation procedure was as follows: the voltage was increased from the open circuit voltage to 4 mV s -1 The constant rate linearly decreases to the preset low voltage value of 0.3 V. When the single cell voltage drops to 0.3 V, the current is quickly cut off, and the battery returns to the open circuit voltage. The above activation steps were repeated, and the polarizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com