A manufacturing process of an asymmetric rigid-flex board

A rigid-flex board, asymmetrical technology, applied in multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of low efficiency, unfavorable long-term production, and large cost waste of traditional processes, so as to reduce production Processing flow, saving processing cost and time cost, ensuring the effect of dry film coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

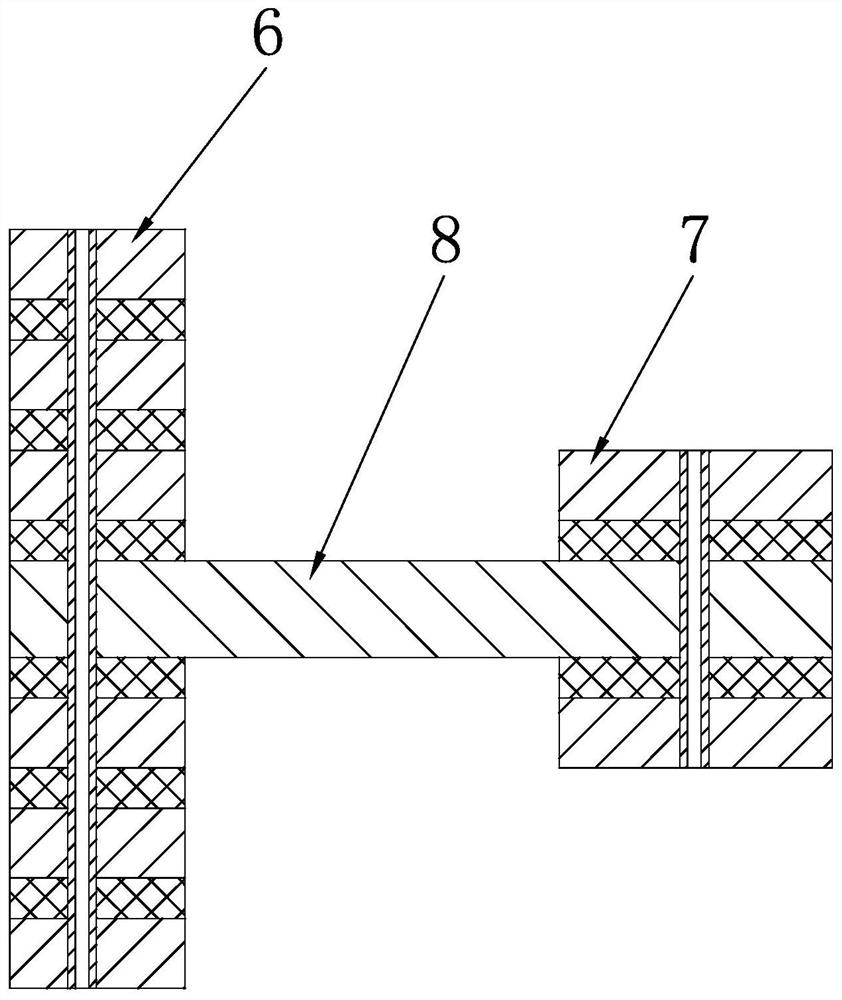

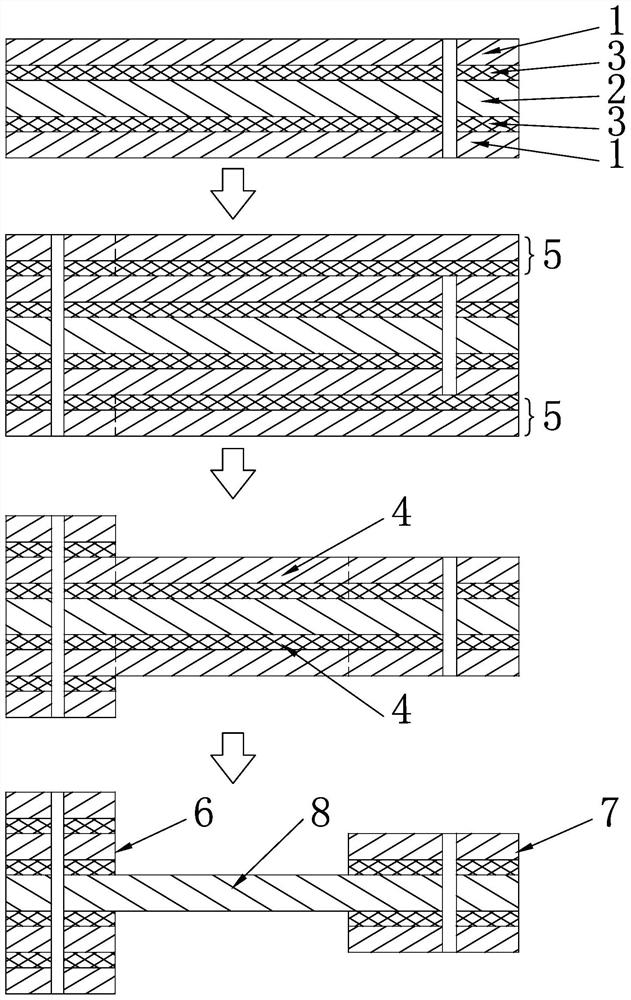

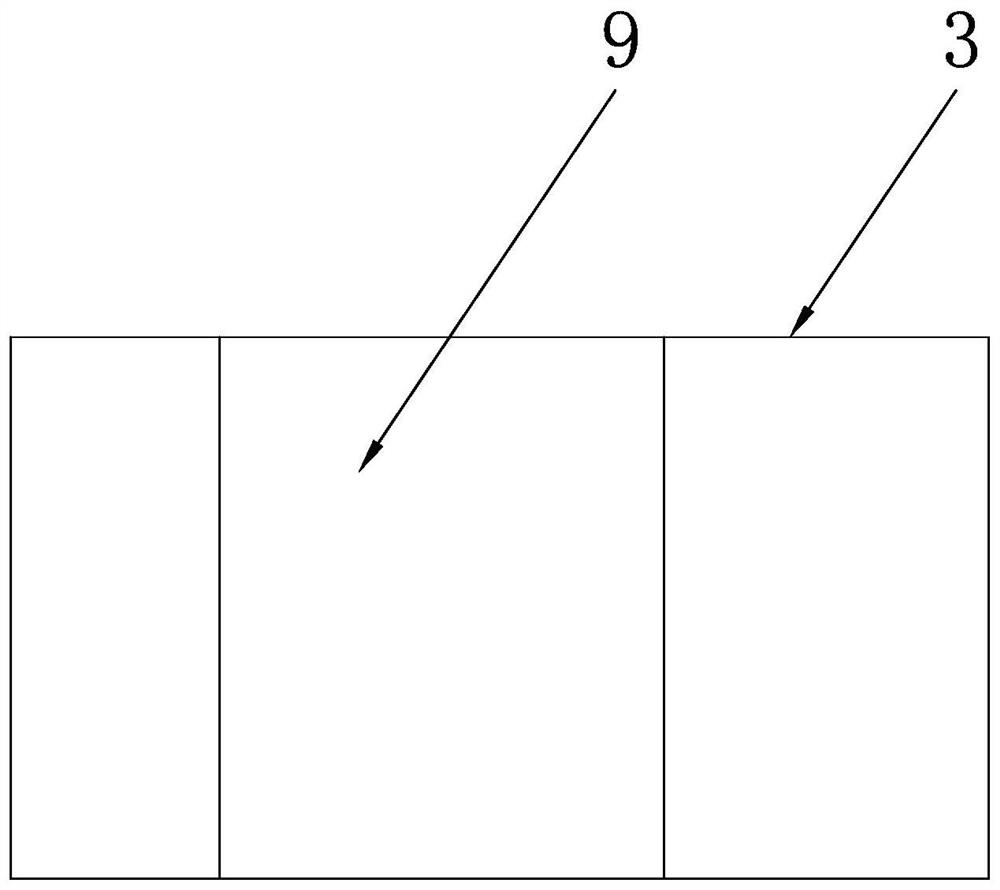

[0034] see figure 1 , the asymmetric rigid-flex board is composed of rigid board 1, flexible board 2 and prepreg 3 according to rigid board 1, prepreg 3, rigid board 1, prepreg 3... rigid board 1, prepreg 3, flexible board 2, The prepreg 3, the rigid board 1...the prepreg 3, the rigid board 1, the prepreg 3, and the rigid board 1 are laminated in sequence. In the process of making rigid-flex boards, the purpose of opening the large cover 5 is to remove part of the rigid board 1 and the prepreg 3 on the upper and lower sides of the rigid-flex board to leak out the sub-board 7 and the small cover 4, and the purpose of opening the small cover 4 is to remove the main board 6 and the rigid board 1 and the prepreg 3 between the sub-board 7 to leak out the flexible board area 8 between the main board 6 and the sub-board 7 .

[0035] A manufacturing process of an asymmetric rigid-flex board of the present invention comprises the following steps:

[0036] S01. Perform preprocessing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com