Operation data monitoring device of intelligent baler

A data monitoring and baler technology, applied to straw baling. It can solve the problems of insufficient packaging quality detection and monitoring technology, and achieve the effect of improving the efficiency of the baling operation and the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

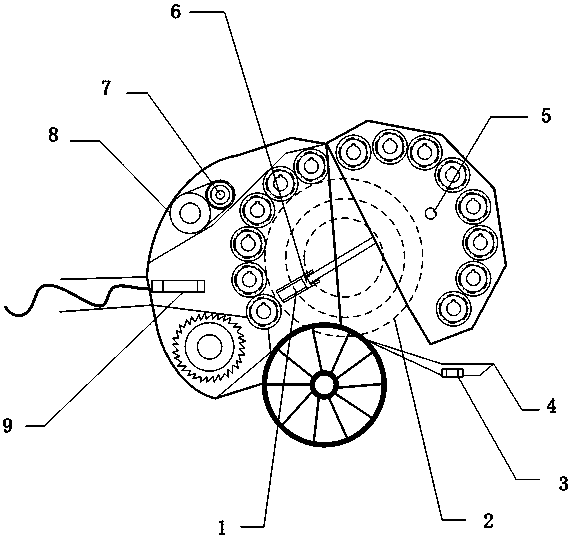

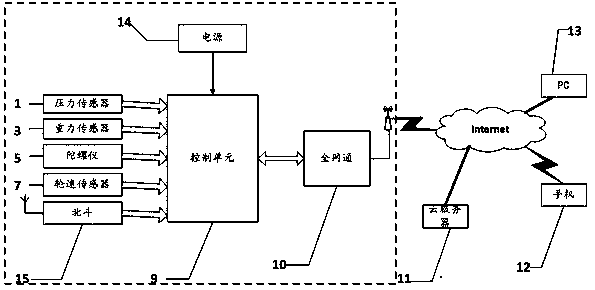

[0012] Such as figure 1 As shown, the pressure sensor is installed in the hydraulic rod that controls the opening of the cabin door to monitor the hydraulic value data, analyze the bale density level in the bale operation, and monitor the hydraulic pressure data proportional to the bale density during the bale forming process in real time. And give the density level to judge whether it has reached the net winding requirements; compared with the existing baler bale density monitoring can only measure the bale density level after the bale is discharged, and this device can be spun out after the bale is wound. The density level is obtained before baling; the wheel speed sensor is installed on the shaft of the net windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com