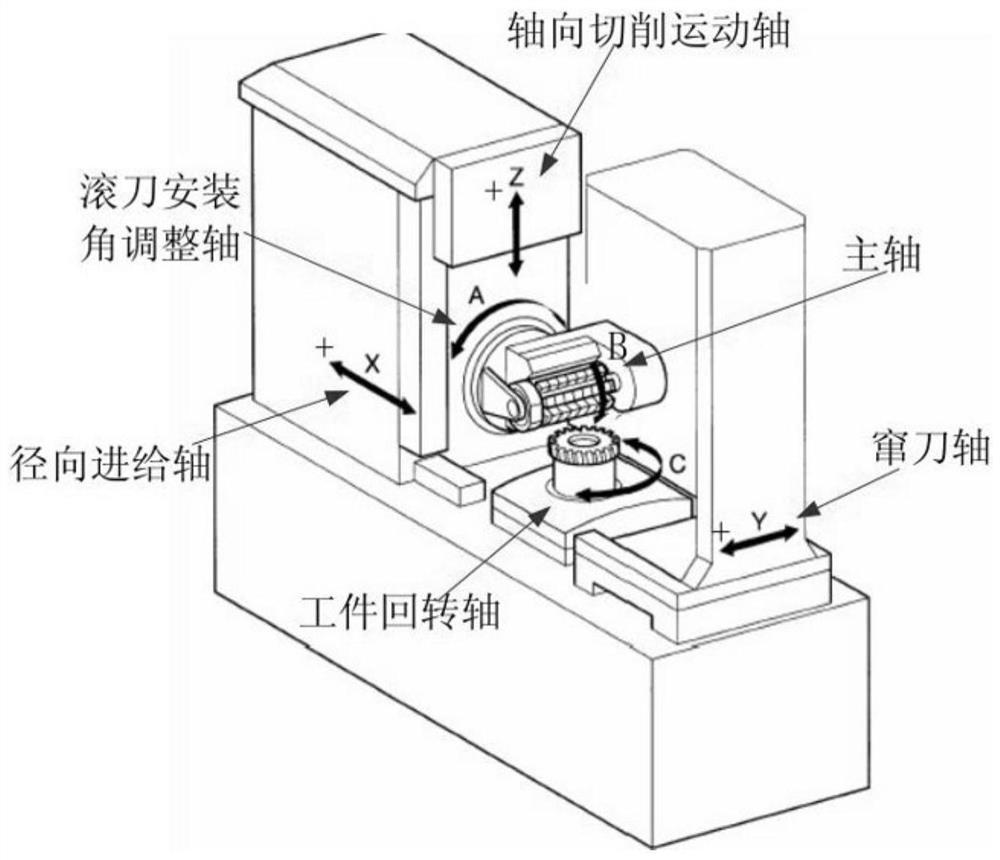

A multi-axis synchronous motion control method for a flexible electronic gearbox

A multi-axis synchronization and motion control technology, applied in gear tooth manufacturing devices, components with teeth, belts/chains/gears, etc., can solve problems such as high price and restricting the development of gear processing equipment manufacturing industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

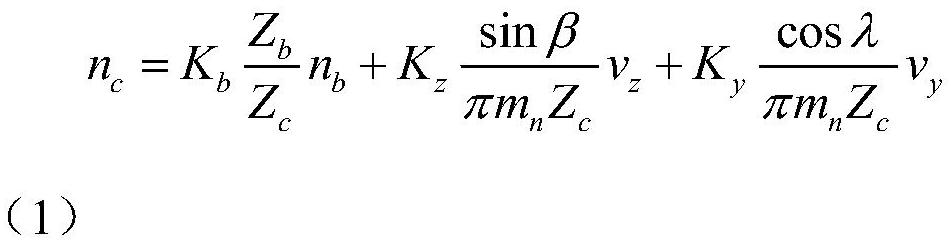

[0051] The tool parameters are: right-hand hob, normal modulus m n Is 1, the number of hob heads Z b Is 1, the hob pressure angle α is 20°, the hob helix angle λ is 1.93°, the installation angle γ is 23.07°, and the hob axial feed is V Z Y > 0; The parameters of the workpiece to be processed are: gear normal modulus m n Is 1, gear teeth number Z c It is 49, the gear pressure angle α is 20°, the gear is right-handed, the helix angle β is 25°, and the total position control time is 11ms, which is divided into 11 position control time points.

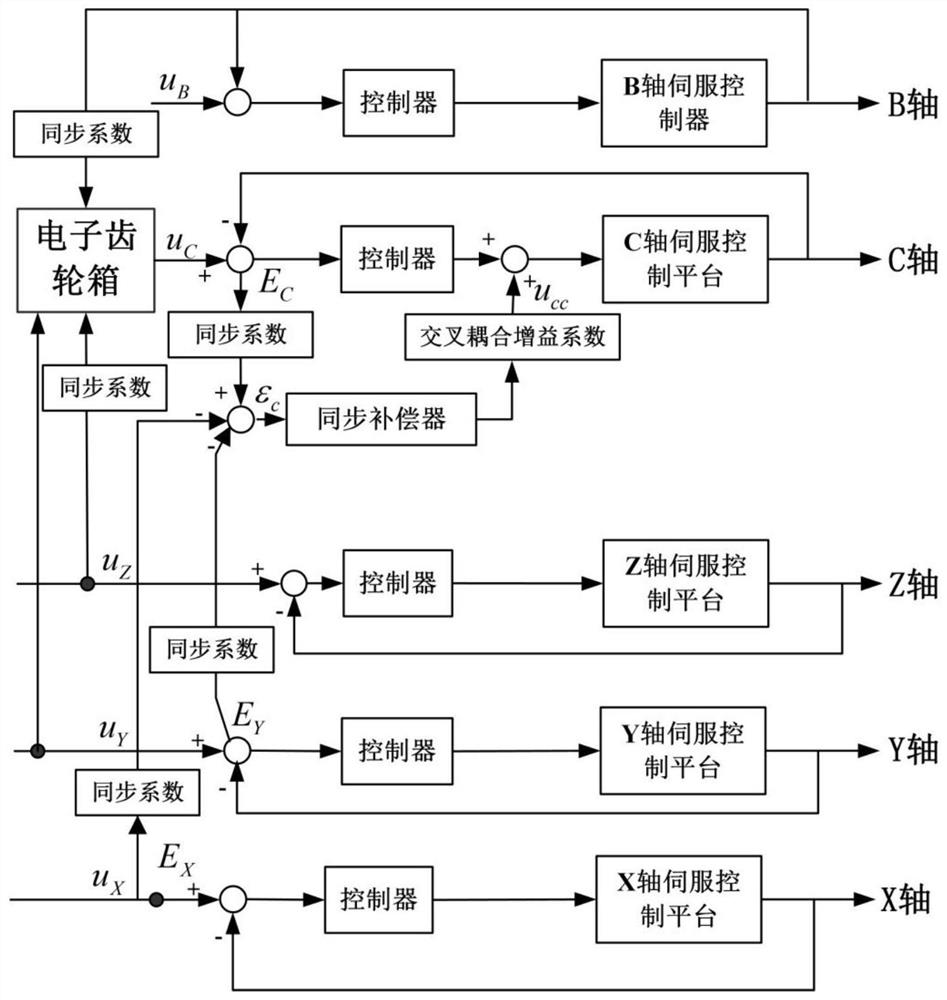

[0052] The specific operation steps of the flexible electronic gearbox multi-axis synchronous motion control method are as follows:

[0053] (1) Determine the type of gear processing by the "diagonal rolling method"

[0054] When using the "diagonal hobbing method" to process helical cylindrical gears, because the tool moves along the Z axis, the C axis produces additional rotation to meet the geometric relationship of the spiral line; when there ...

Embodiment 2

[0094] The tool parameters are: left-hand hob, normal modulus m n Is 2, the number of hob heads Z b Is 1, hob pressure angle α is 20°, hob helix angle λ is 2.01°, installation angle γ is 22.99°, hob axial feed V Z > 0, hob tangential feed V Y n Is 2, gear teeth number Z c It is 27, the gear pressure angle α is 20°, the gear is left-handed, the helix angle β is -25°, and the total position control time is 11ms, which is divided into 11 position control time points.

[0095] The specific operation steps of the multi-axis synchronous motion control method of the flexible electronic gearbox are as follows

[0096] (1) Determine the type of gear processing by the "diagonal rolling method"

[0097] When using the "diagonal hobbing method" to process helical cylindrical gears, because the tool moves along the Z axis, the C axis produces additional rotation to meet the geometric relationship of the spiral line; when there is a tool shifting process requirement, the tool moves along the Y axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com