Magnetic field controllable sustained-release magnetic substance thickening liquid flow polishing pad and polishing method

A technology of magnetic substances and polishing pads, applied in the direction of grinding tools, etc., can solve the problem of fast loss of polishing liquid, and achieve the effect of reducing the total processing time, easy cleaning, and improving polishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

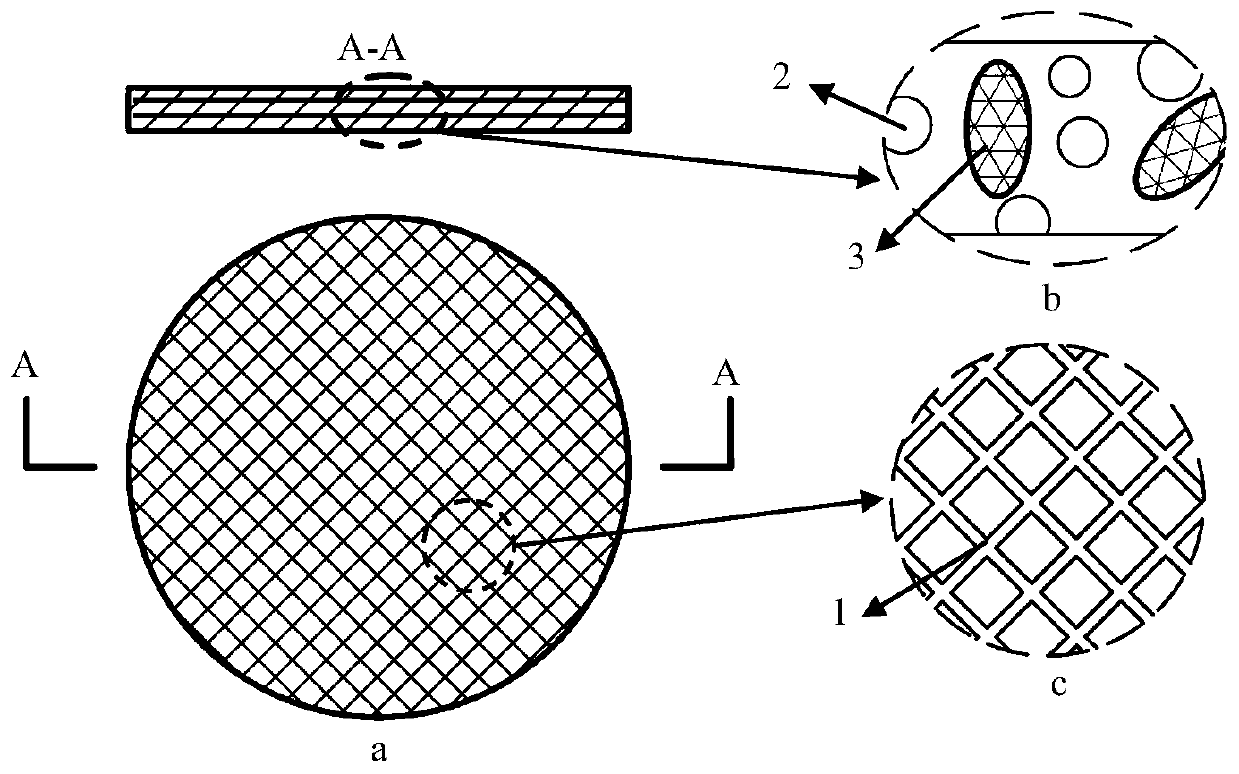

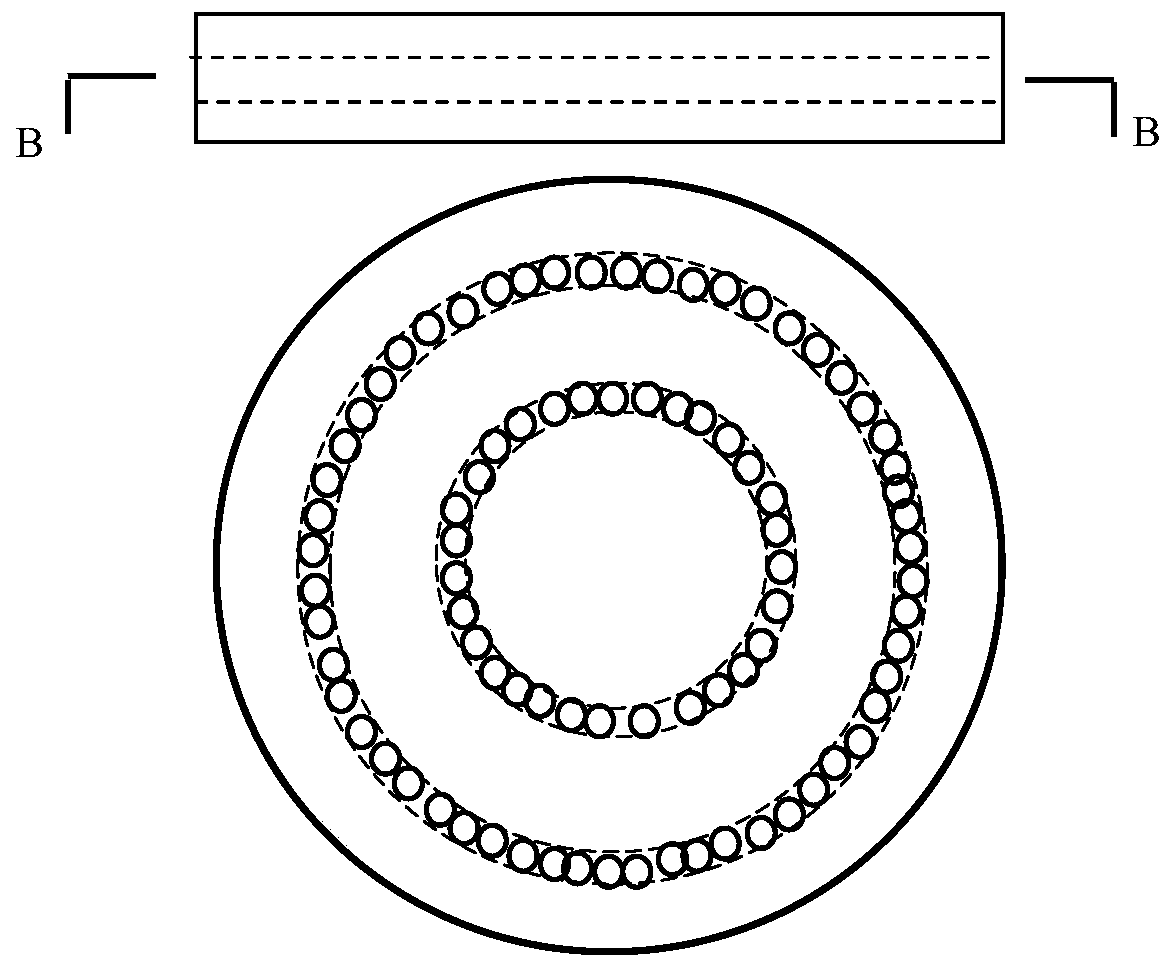

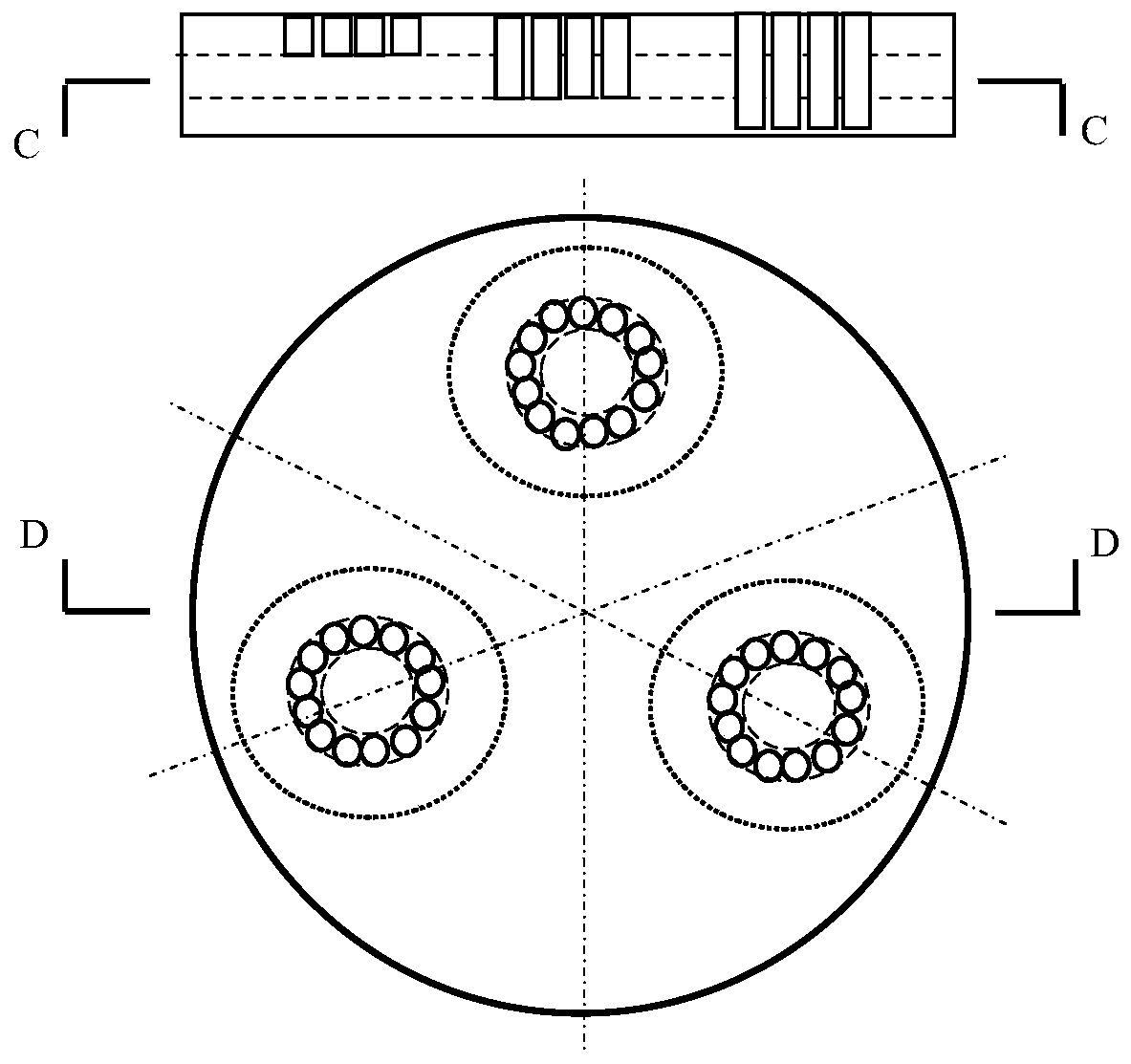

[0048] refer to Figure 1 ~ Figure 4 , a polishing pad with magnetic field slow-release polishing material characteristics, including diamond-shaped lines 1, pores 2, and slow-release abrasive capsules 3, the polishing pad is a porous wear-resistant polishing pad, and the polishing pad is reserved. Pores 2 are embedded with abrasives A capsule containing magnetic abrasives, a thickening phase and an acid-base agent. During the polishing process, the abrasive capsule is subjected to the action of the magnetic field, and the magnetic abrasive breaks through the shell of the slow-release abrasive capsule 3, releasing the polishing material therein, gradually dispersing and dissolving in water (or aqueous solution), and forming a slow-release magnetic substance thickened liquid flow polishing liquid. Realize the flexible slow-release thickened polishing of the workpiece....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com