A safety detection system for xy axis system of spraying station

A technology of safety inspection and station, which is applied in engineering safety devices, mechanical equipment, optical device exploration, etc., can solve problems such as operator injury and hidden dangers of mechanical equipment, and achieve the effect of reducing safety accidents and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

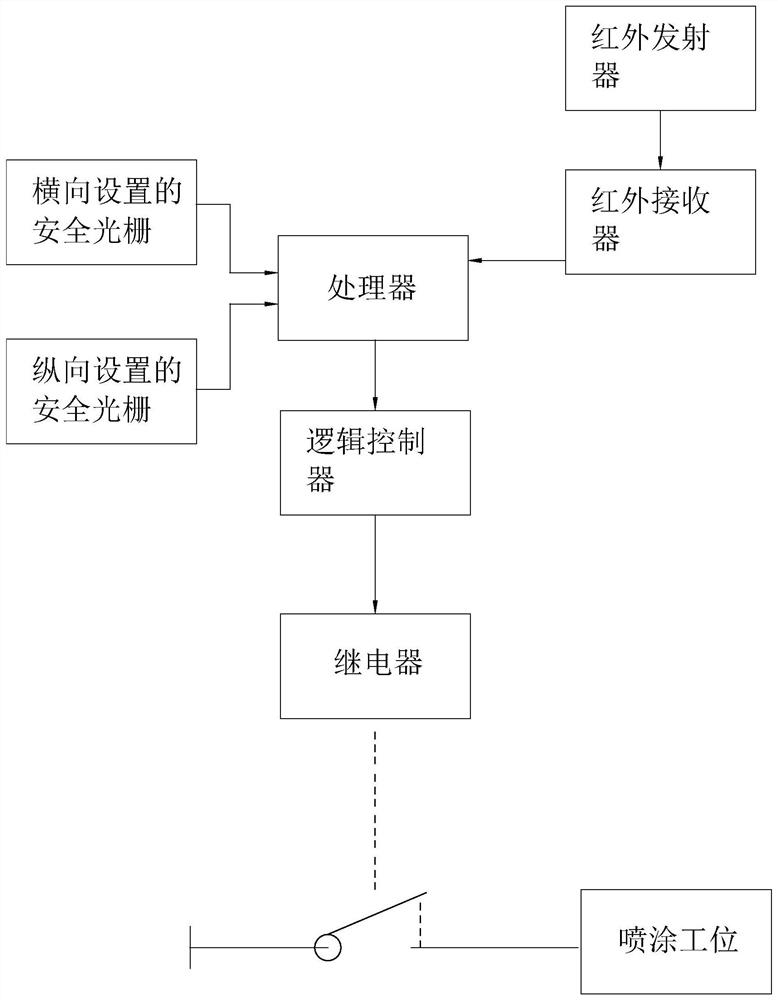

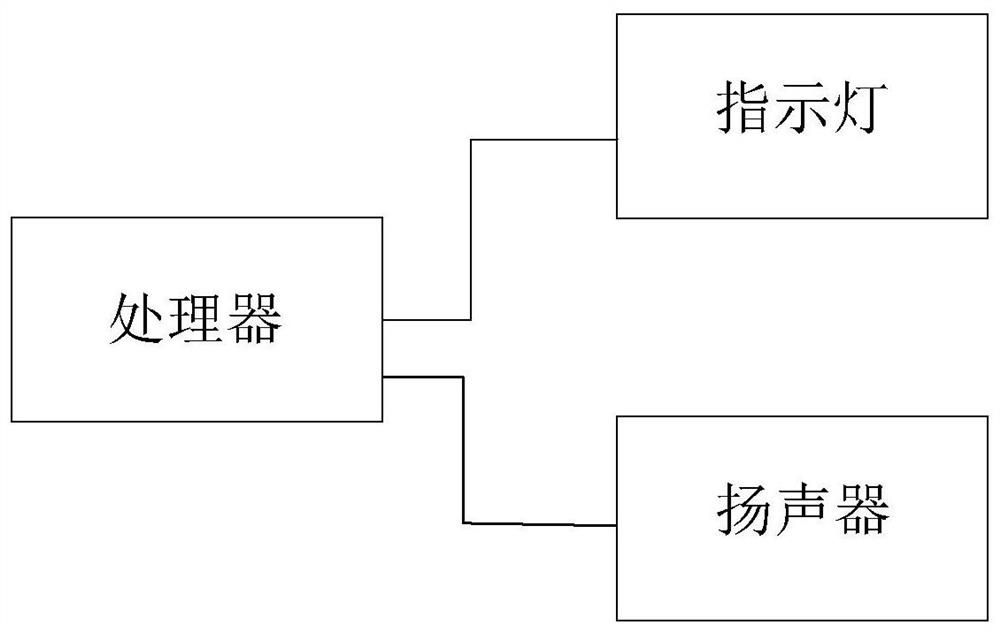

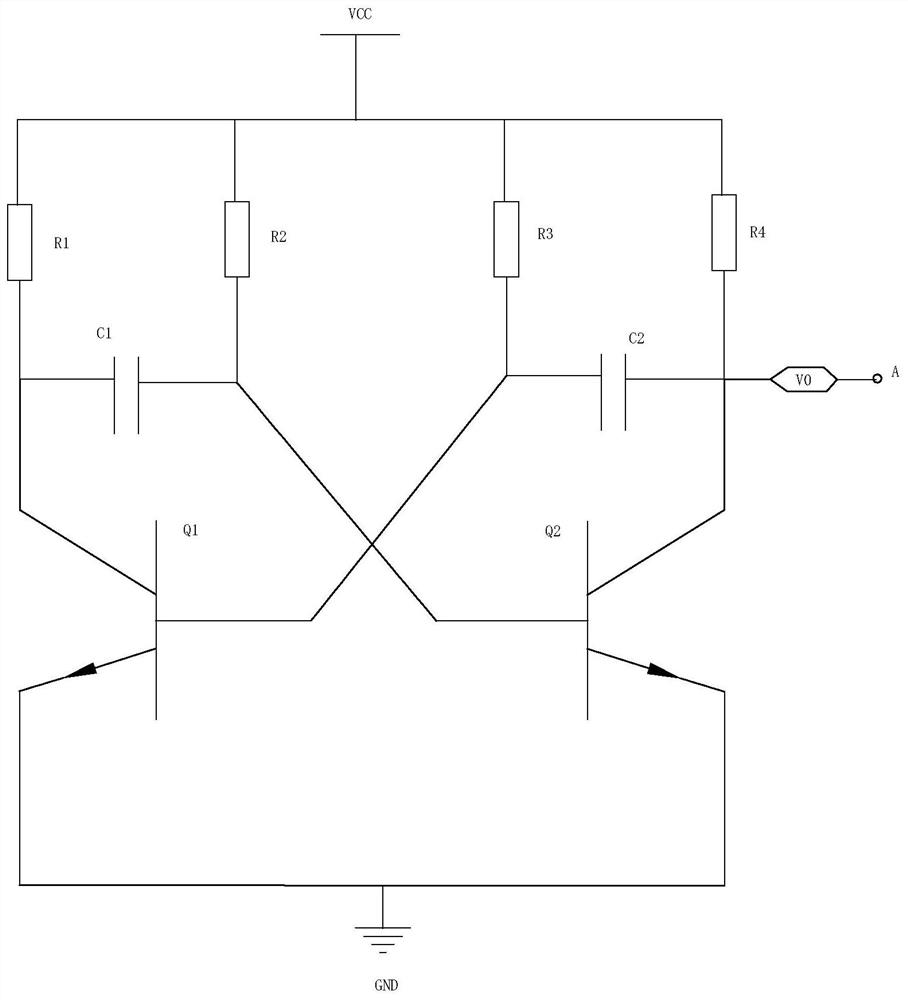

[0027] Embodiment: A safety detection system for the XY axis system of a spraying station, such as figure 1 As shown, it includes the safety grating set horizontally and the safety grating set vertically. The above-mentioned horizontally set safety grating is set under the spraying station and is as wide as the spraying station. The height of the horizontally set safety grating is set at 10cm from the ground- 20cm. In this embodiment, the distance from the ground is 15cm. This setting can ensure that as long as the operator enters the area of the safety grating, the action of detecting the entry of the operator can be completed. The vertically arranged safety grating is set at the entrance on both sides of the spraying station. , used to detect entering operators. After a person strays into the safe area, the safety grating scans and receives a signal immediately. The above-mentioned safety grating arranged horizontally and the safety grating arranged vertically form a spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com