Twin-bridge fin structure and twin-bridge fin machining die

A fin mold and fin technology are applied in the field of double bridge fin structure and double bridge fin processing mold, which can solve the problems of easy deformation of fin structure, and achieve the effect of improving qualification and continuous processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

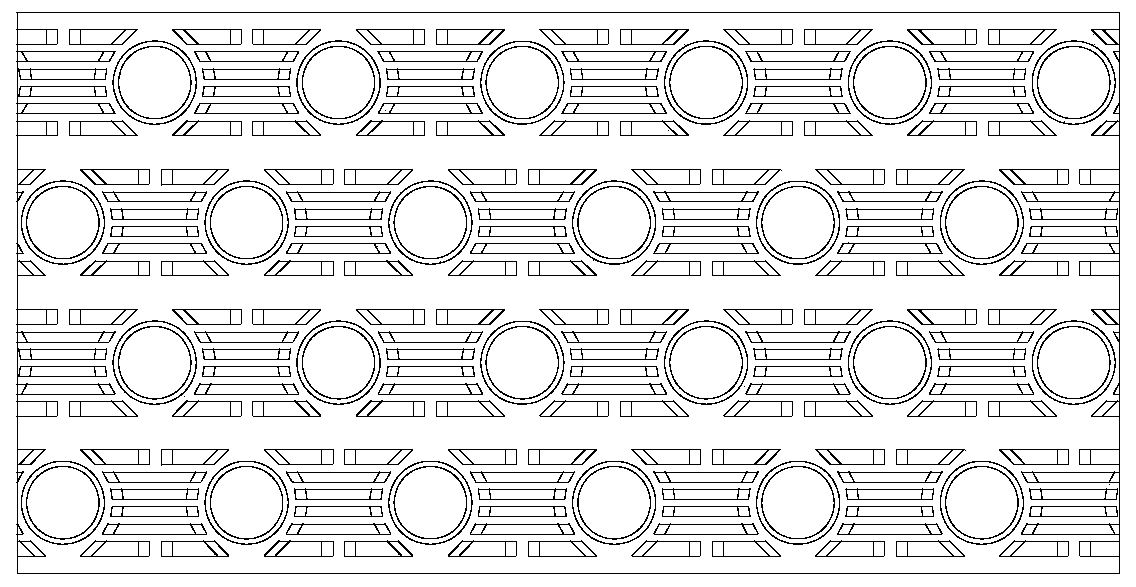

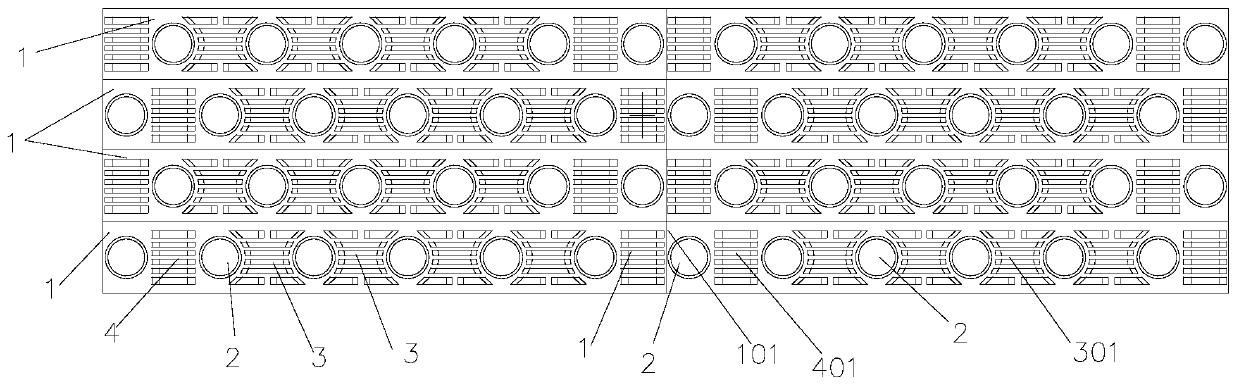

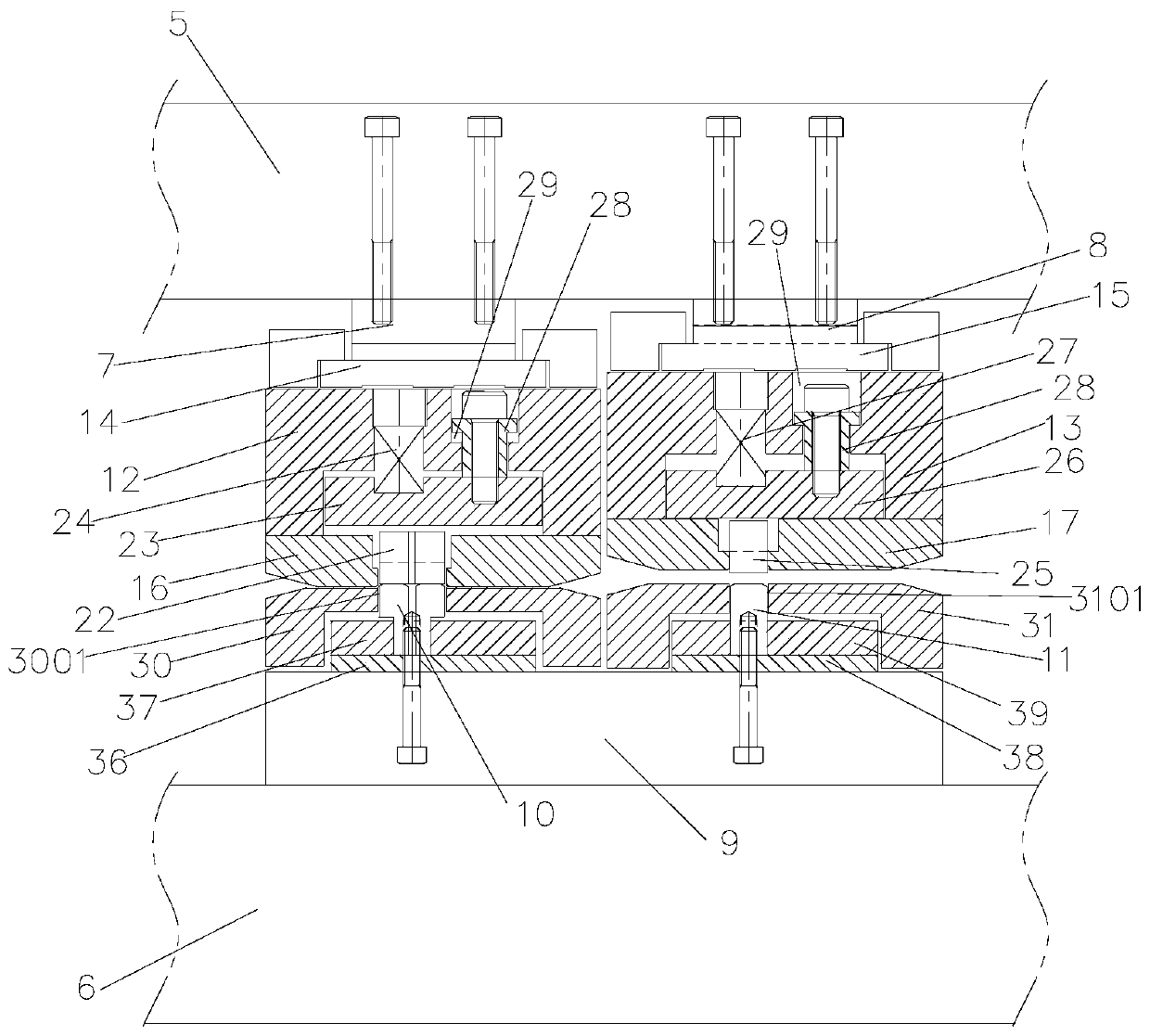

[0023] Examples such as figure 2 As shown, a double bridge fin structure includes at least one row of fin units 1 , and the double bridge fin structure in this embodiment has four rows of fin units 1 arranged side by side. A group of expansion rod installation holes 2 are distributed on each row of fin units 1, and the expansion rod installation holes 2 are equidistantly distributed along the length direction of the fins. The minimum distance for one line is a step.

[0024] Each row of fin units 1 is provided with a first bridge unit 3 or a second bridge unit 4 on both sides of the expansion rod installation hole 2. The double bridge fin structure is installed between the second bridge unit 4 and the expansion rod. Cutting is made between the holes 2 to form a single fin structure. The first bridge unit 3 includes a group of special-shaped bridges 301 with different lengths. The distances are the same, so that the end of the special-shaped bridge piece 301 is surrounded b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com