Cup-shaped sample unloading apparatus and method

An unloading device, cup-shaped technology, applied in the preparation of test samples, etc., can solve the problems of low cost, difficult unloading of samples, and damage efficiency of samples, and achieve the effect of improving experimental efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

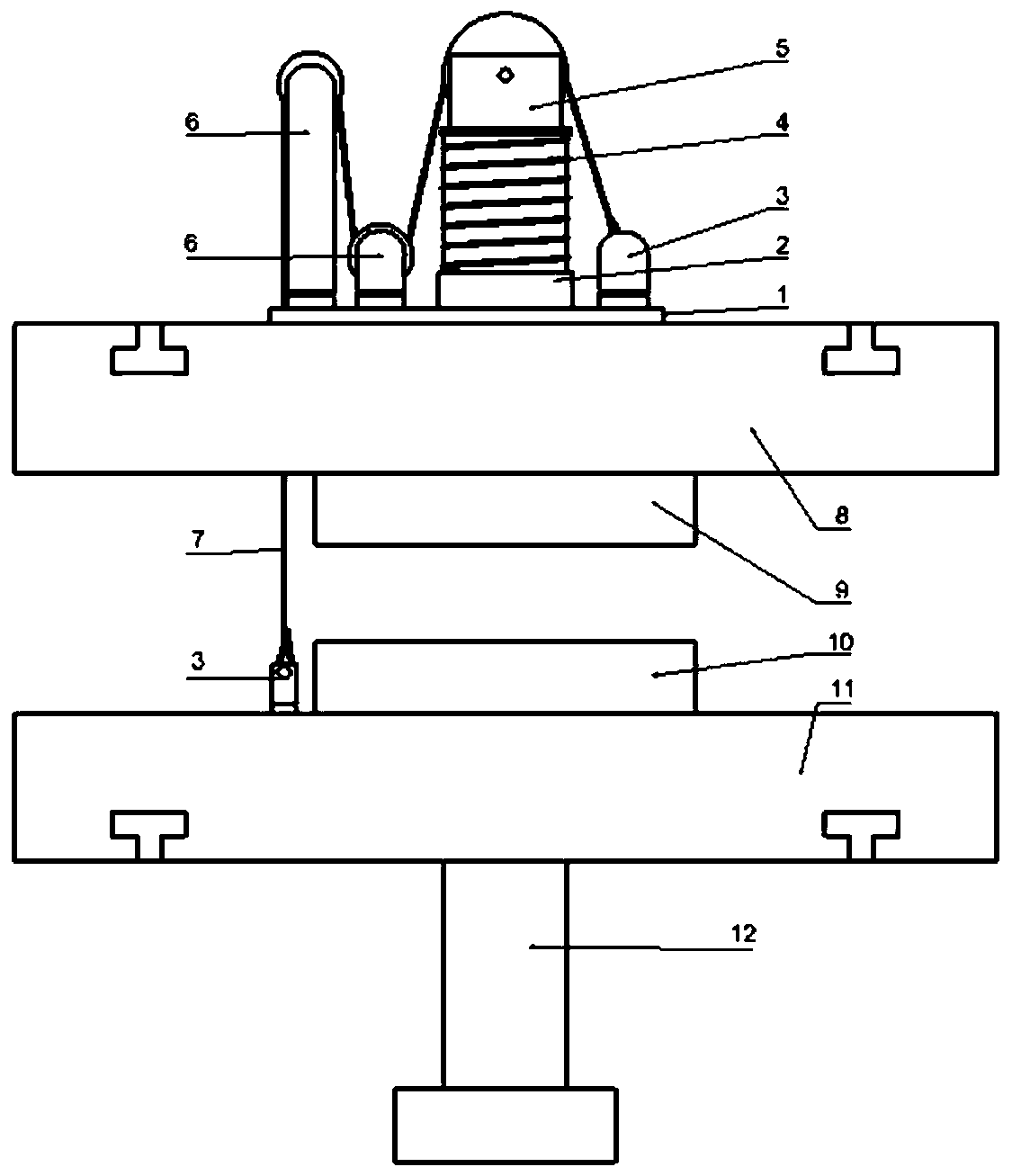

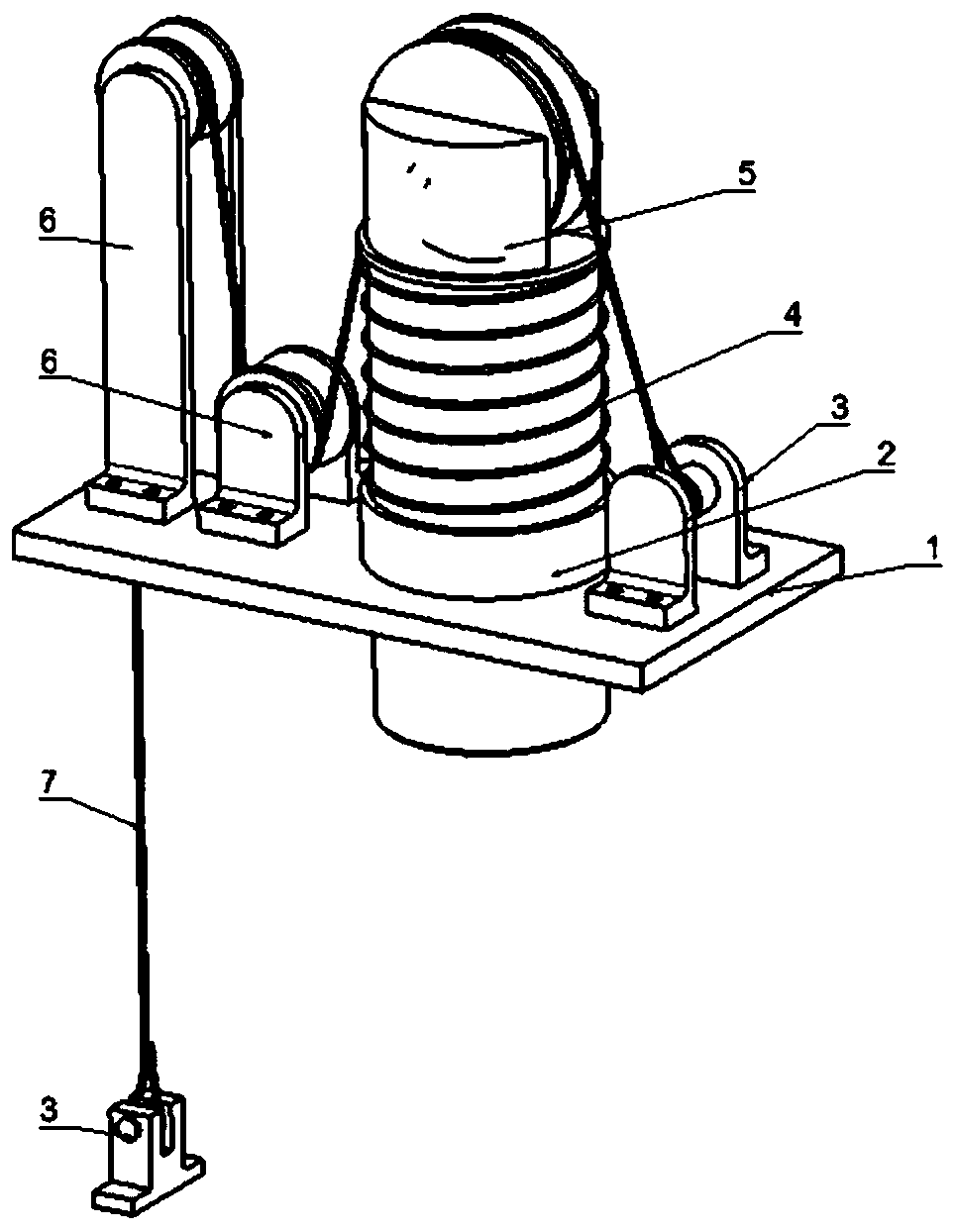

[0024] See figure 1 , figure 2 , a cup-shaped sample unloading device, the device is assembled on the testing machine for lug test or secondary embrittlement test processing cup-shaped sample, the testing machine has a fixed platform and a liftable moving platform, the moving platform A lower mold is fixedly connected, an upper mold is fixedly connected with the fixed platform, and the upper mold and the lower mold are arranged oppositely.

[0025] The cup-shaped sample unloading device includes a steel wire rope 7, high fixed pulley assembly 6, low fixed pulley assembly 6, two fixed piles 3, sample unloading guide post 5, spring 4, base 1, positioning sleeve 2; high fixed pulley block Part 6, low fixed pulley assembly 6, positioning sleeve 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com