Automatic detection method and device for state of liquid monitoring sensor

An automatic detection device and a technology for monitoring sensors, applied in the field of monitoring, can solve problems such as low maintenance efficiency, inability to achieve sensor contamination, failure, and increased maintenance procedures, and achieve the effect of efficient and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

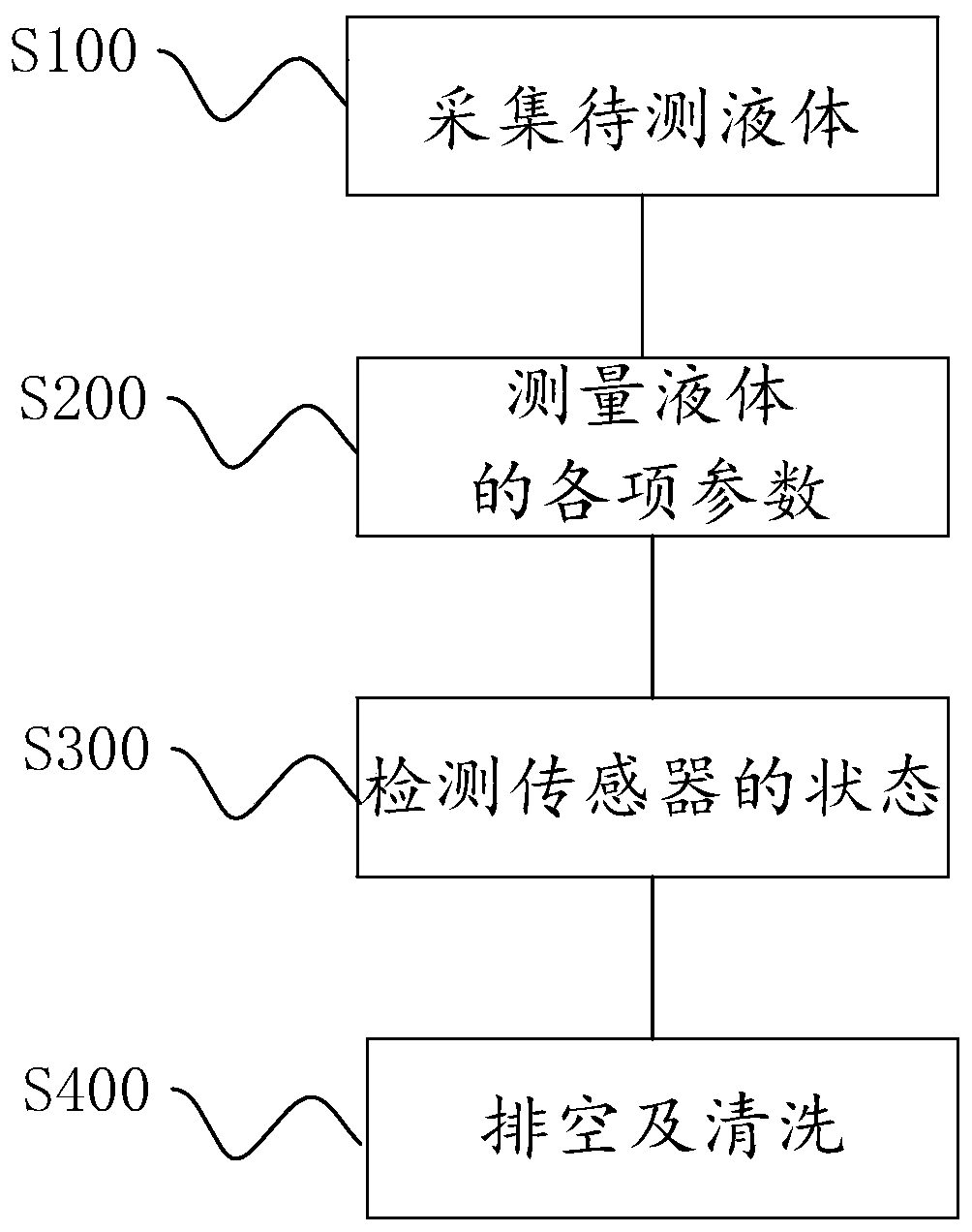

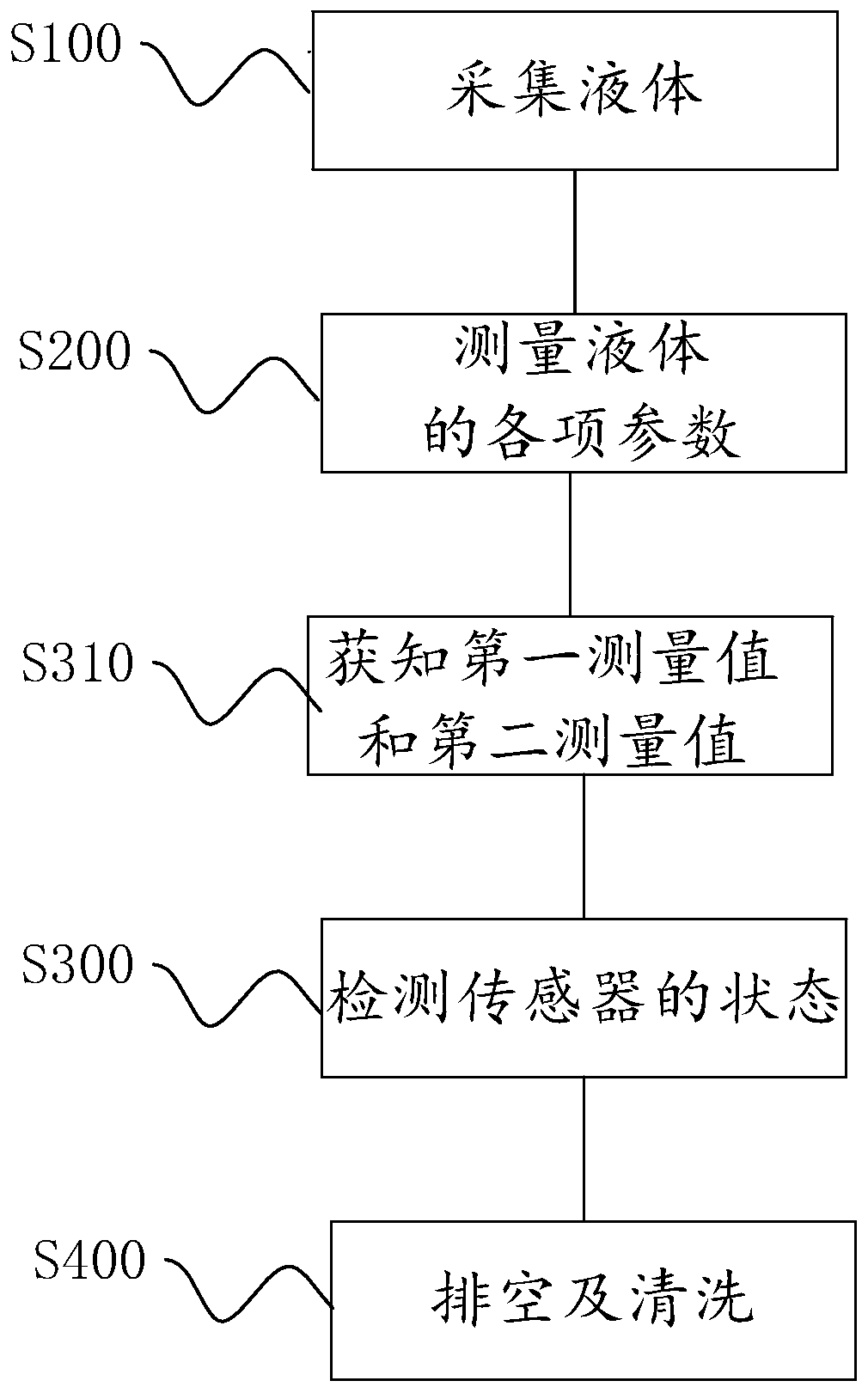

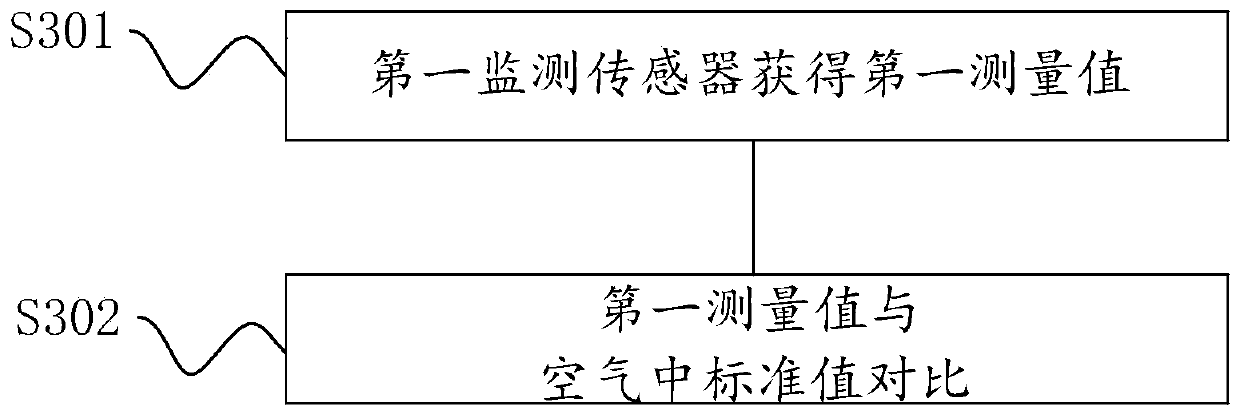

[0080] see image 3 with Figure 5 , the monitoring sensor used in this embodiment is one or both of the dissolved oxygen sensor 121 or the conductivity sensor 122 . The method for detecting the state of the monitoring sensor of this embodiment is as follows:

[0081] Step S301, the dissolved oxygen sensor or the conductivity sensor measures the dissolved oxygen or conductivity of the air to obtain the first measurement value, specifically, by starting the valve to control the sensor to be in the air, the liquid level of the liquid is at the first level F1, and the sensor is The parameter of the air is measured, and the obtained measured value is the first measured value. Wherein, the first liquid level F1 is any position where the monitoring sensor is completely separated from the liquid.

[0082] In step S302, the first measured value is compared with the standard value of dissolved oxygen and / or conductivity in the air, and the dissolved oxygen or conductivity in the air...

Embodiment 2

[0086] see Figure 4 , Figure 7a with Figure 7b , the monitoring sensor used in this embodiment is the turbidity sensor 123 . The method for detecting the state of the monitoring sensor of this embodiment is as follows:

[0087] In step S301', the turbidity sensor obtains a first measurement value, specifically, by starting the valve to control the liquid to be at the first liquid level, that is, the intersection point of the turbidity sensor and measuring the first measurement value. Specifically, the first liquid level is the position of the intersection of the emitting light path and the 90-degree receiving light path of the turbidity sensor, and the turbidity sensor is in the standard medium.

[0088] Step S302', the turbidity sensor is located at the second liquid level F2, and the turbidity of the air is measured to obtain the second measured value, specifically, the liquid level is controlled to continue to drop by starting the valve until the liquid level is below...

Embodiment 3

[0095] The monitoring sensors used in this embodiment are dissolved oxygen sensors, conductivity sensors and pH sensors. The method for detecting the state of the monitoring sensor of this embodiment is as follows:

[0096] Because the dissolved oxygen sensor, conductivity sensor and pH sensor all need temperature compensation, they all have temperature measurement function. Before detecting the state of the sensor, set the dissolved oxygen sensor, the conductivity sensor and the pH sensor in the liquid at the same time to measure the temperature of the liquid at the same time; all generate temperature measurement values, compare each generated temperature measurement value, and all differences When the values are all lower than the set temperature difference d2t, the states of the three sensors are normal. Otherwise, the sensor fails, where d2t can be set according to the actual parameters of the sensor, specifically, the set temperature difference is the one with the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com