Operation method and device of cleaning robot

A technology for cleaning robots and operating methods, which is applied in the field of operating methods and devices for cleaning robots, can solve problems such as unproposed solutions, achieve the effect of improving cleaning coverage and avoiding missing uncleaned areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

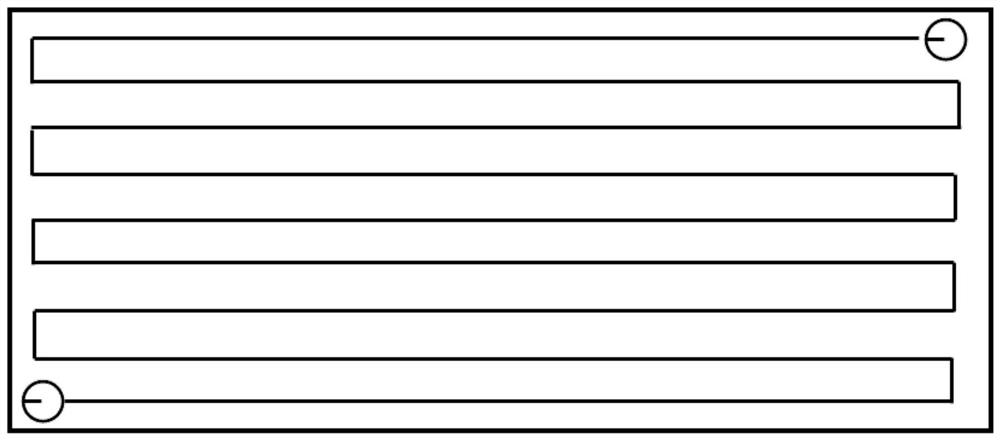

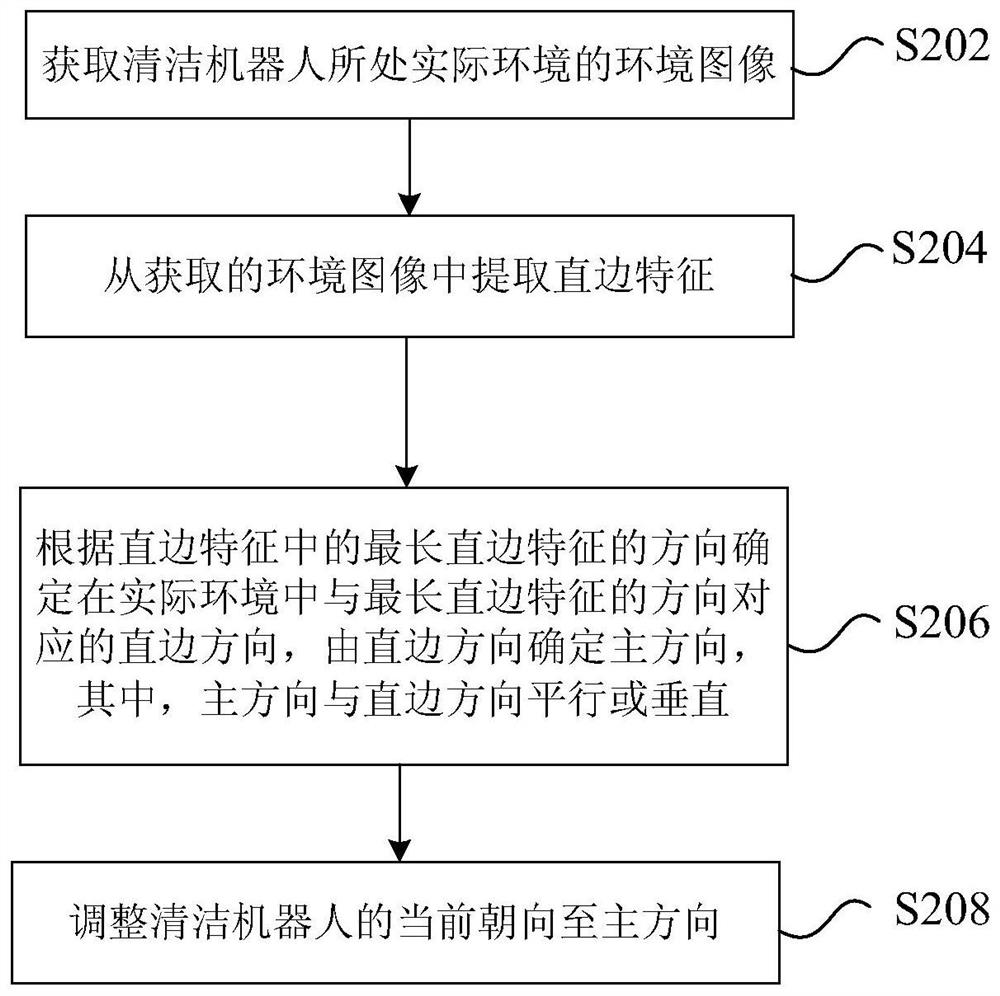

[0067] Embodiment one, Figure 4 is based on Figure 3b Shown is a flow chart of an area division method for a cleaning robot in an embodiment in which a photo of the cleaning robot in its actual environment is captured by an image acquisition device installed on the top of the cleaning robot and the lens is vertically upward, Wherein, the photo is a photo of the lower surface of the horizontal plane above the top of the cleaning robot. like Figure 4 As shown, the specific steps of the method are as follows:

[0068] Step S401: The image acquisition device (such as a video camera or camera) acquires environment images containing information about the environment around the cleaning robot, wherein at least one environment image contains straight-edge features in the environment.

[0069] Step S402: The cleaning robot extracts straight edge features from the environment image.

[0070] Step S403: The cleaning robot calculates the angle between the current orientation of the...

Embodiment approach 2

[0077] Embodiment 2 provides an area division method for a cleaning robot, which specifically includes the following steps:

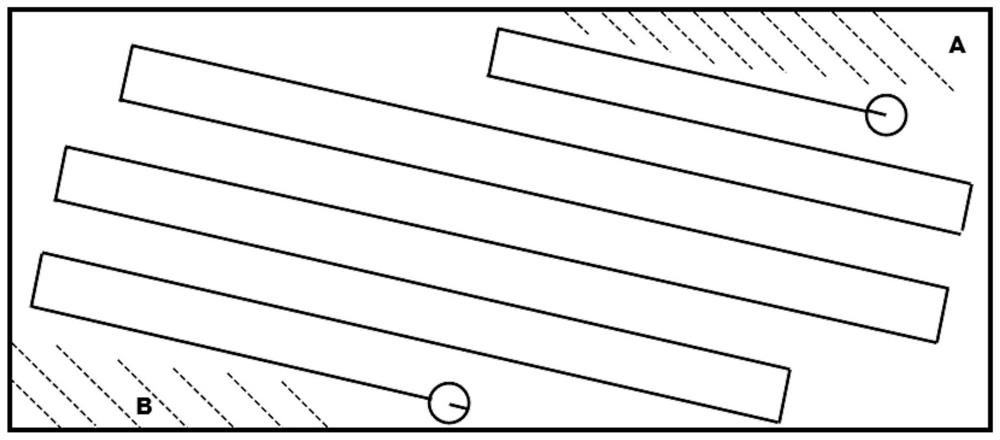

[0078] Step S501: The cleaning robot rotates once on the spot, so that the ranging device (such as TOF or laser radar) obtains the ranging information of the cleaning robot and nearby obstacles around it, and establishes an electronic map (such as Figure 5 shown. Figure 5 is a schematic diagram of the initial environment of the cleaning robot according to one embodiment of the present invention).

[0079] Step S502: The cleaning robot extracts straight edge features from the electronic map, such as Figure 5 For example, the straight edge feature can be the projection line of the side of the wall near the cleaning robot facing the side of the cleaning robot on the ground, and the side of the cabinet or bed near the cleaning robot facing the side of the cleaning robot on the ground Projecting straight lines, etc.

[0080] Step S503: The cleaning rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com