Method for producing firework aluminum powder

A technology for aluminum powder and fireworks, applied in the field of aluminum powder production for fireworks, can solve the problems of excessive powder particles, poor atomization effect, uneven powder, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

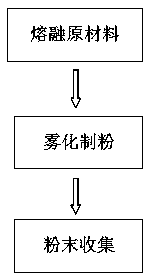

[0026] As shown in the accompanying drawings: a method for producing fireworks aluminum powder, comprising the following steps:

[0027] The first step is to melt the raw materials, place the aluminum powder raw materials in a vacuum melting furnace, and heat them with a medium-frequency induction heater to fully melt them to form molten aluminum;

[0028] The second step is to atomize and make powder. The melted aluminum melt flows into the atomization chamber through the guide tube, and is atomized by the ultrasonic atomizer in the atomization chamber to fully atomize the aluminum melt. The atomized molten aluminum is cooled by the cooling system to form powder;

[0029] The third step is powder collection. The powder is collected by the powder collection system, and then packaged and packaged after collection.

[0030] Ultrasonic waves are used to atomize the molten aluminum, which effectively improves the effect and efficiency of the atomization. Preferably, the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com