Workpiece nitriding layer removing device and system

A technology for nitriding layer and workpiece is applied in the field of workpiece nitriding layer removing device and its system, which can solve problems such as adverse effects on operators, inability to meet high-efficiency automation, environmental pollution, etc., and achieve environmental friendliness, reduce adverse effects, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

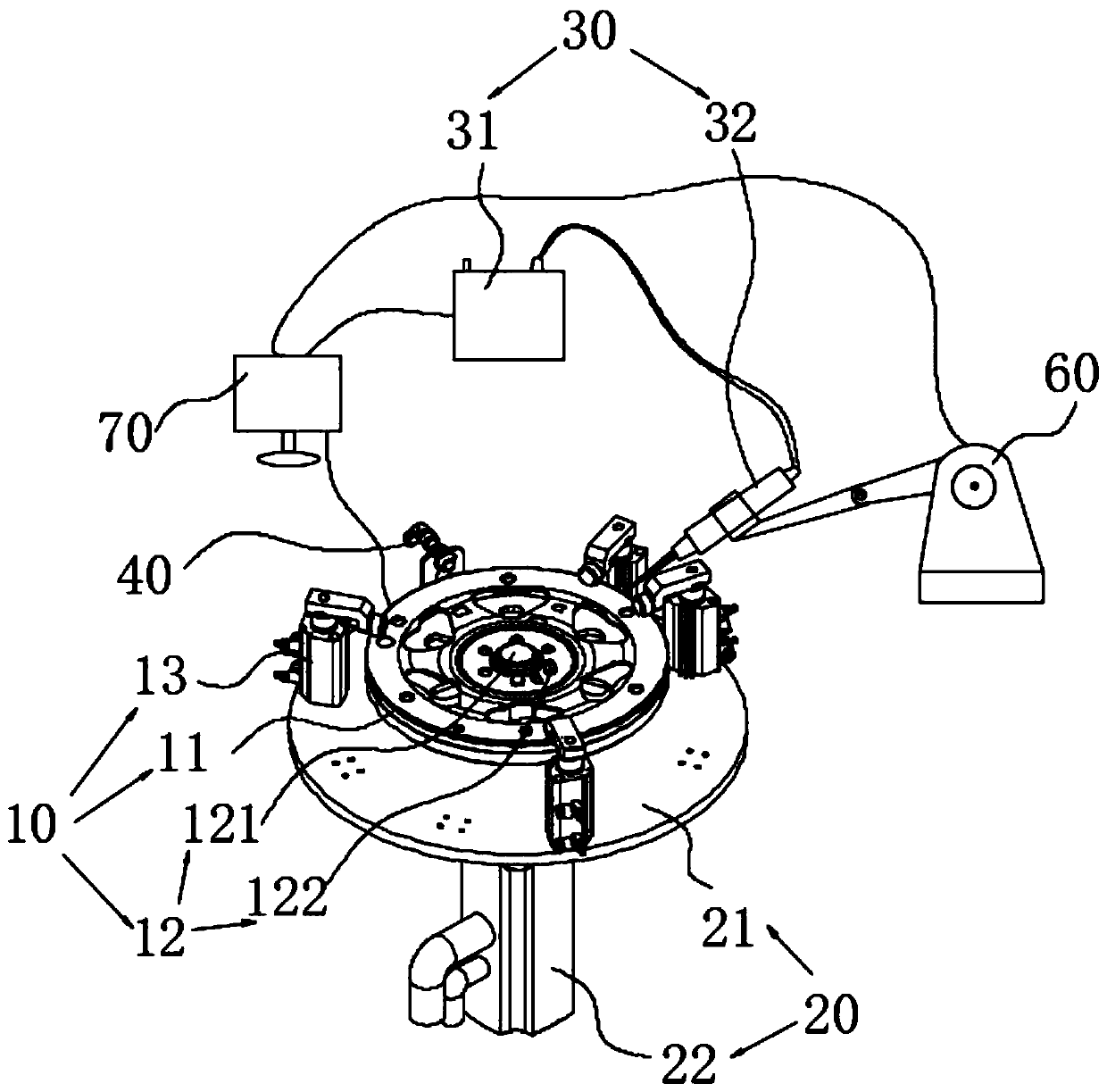

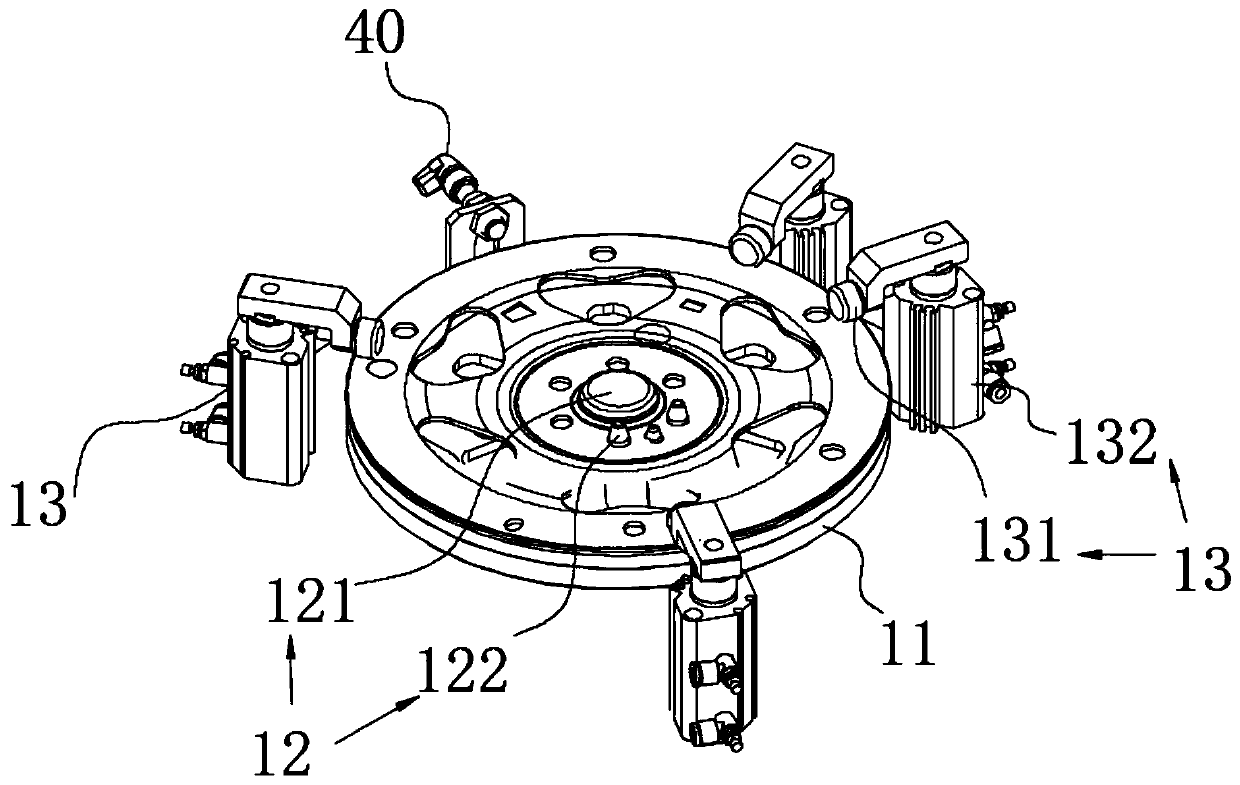

[0027] Such as figure 1 As shown, the present invention provides a preferred embodiment of a workpiece nitride layer removal device.

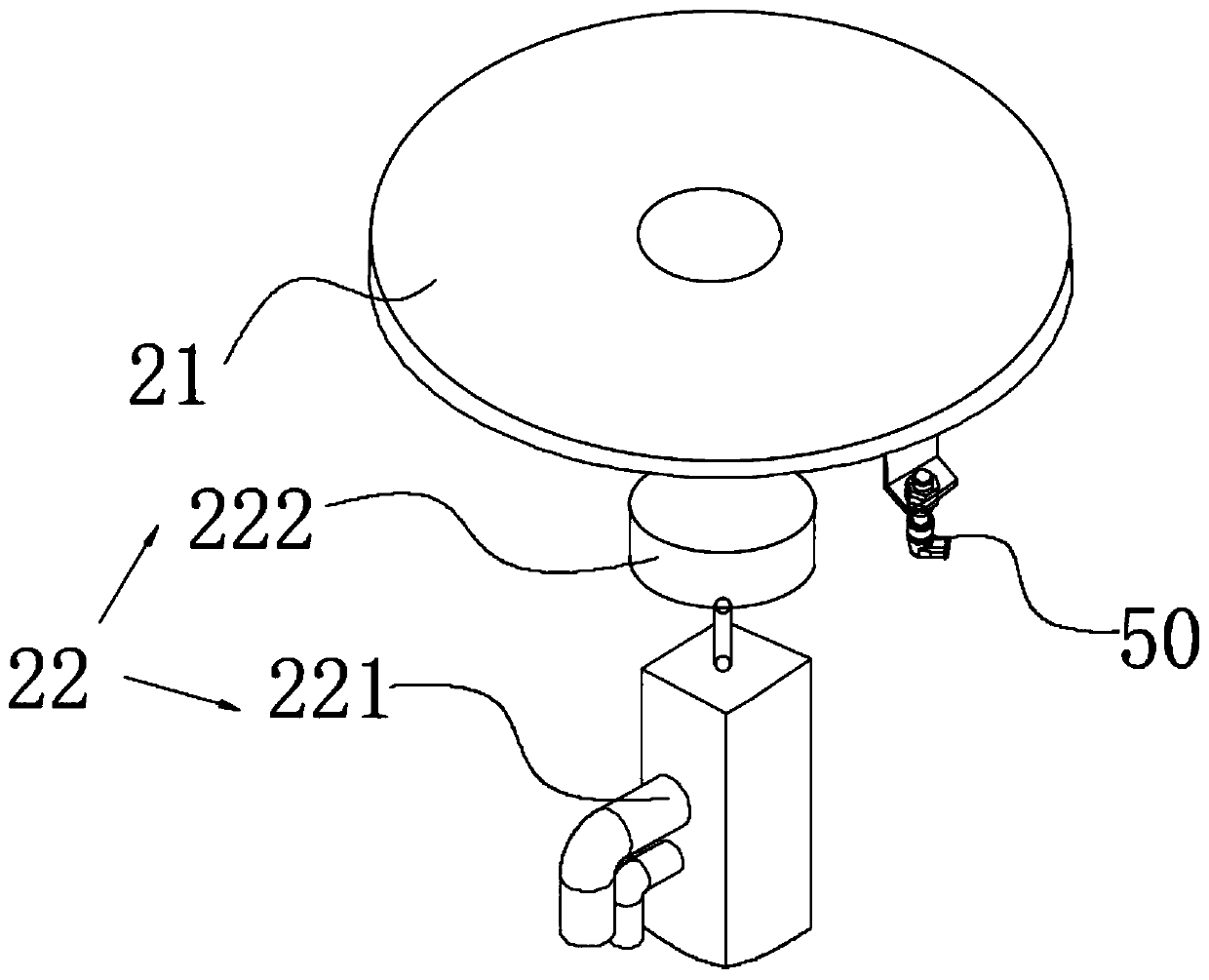

[0028] A workpiece nitriding layer removal device, comprising a workpiece positioning mechanism 10 for positioning a workpiece 200; a rotary drive mechanism 20 connected to the workpiece positioning mechanism 10; and a laser emitting mechanism 30 for emitting laser ablation to remove the workpiece 200 The nitriding layer on the surface; wherein, during the laser emitting mechanism 30 emits laser ablation to remove the nitriding layer, the rotating drive mechanism 20 drives the workpiece positioning mechanism 10 to rotate in conjunction with the progress of removing the nitriding layer, so as to drive the workpiece 200 to rotate .

[0029] The workpiece 200 is positioned by setting the workpiece positionin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap