Mechanical type blister nail nailing machine

A nailer and mechanical technology, applied in the field of nailers, can solve the problems of complex structure, large volume, and long time for nailing the nail feeding mechanism, and achieve the effect of simple structure, small size, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

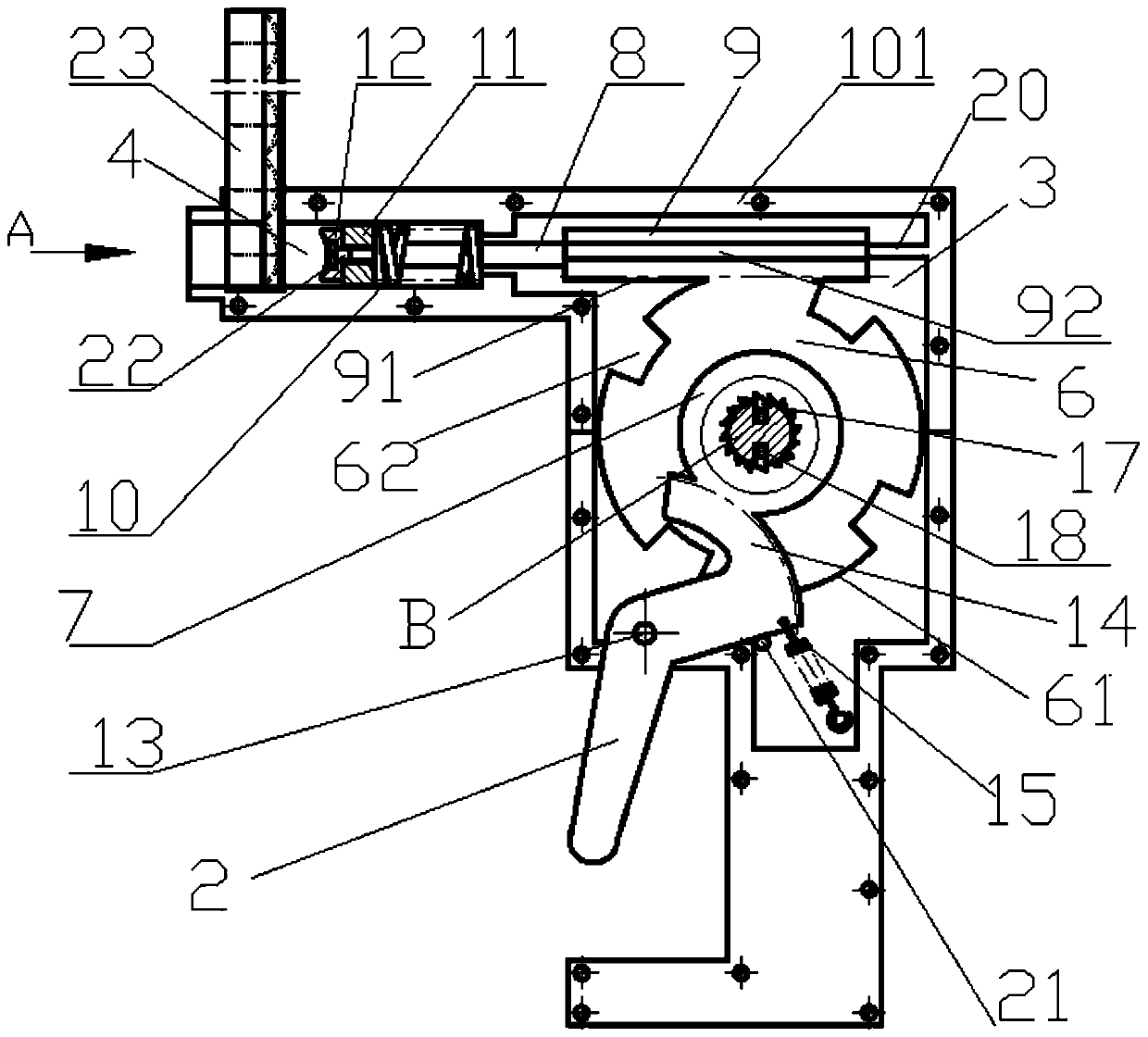

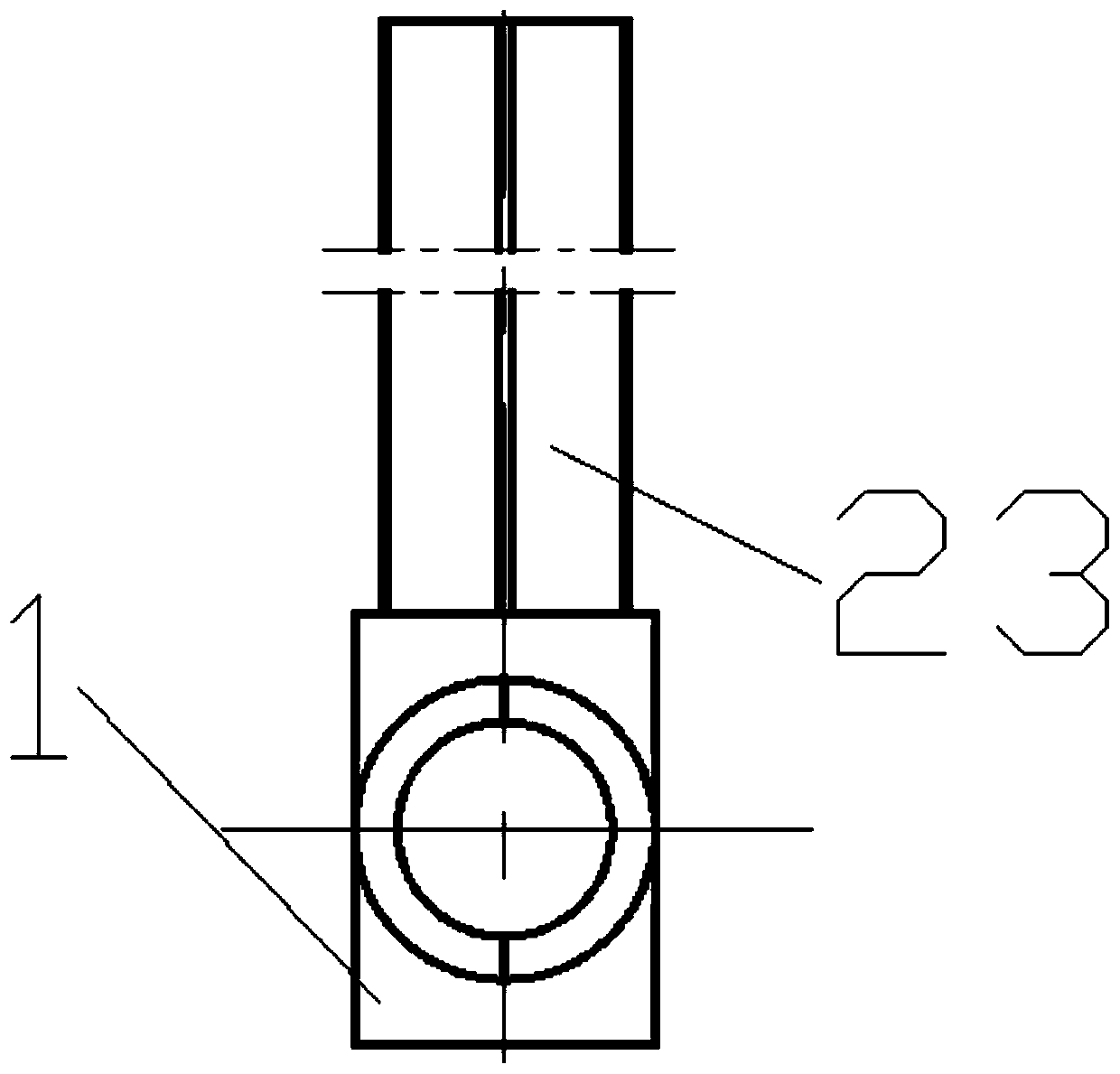

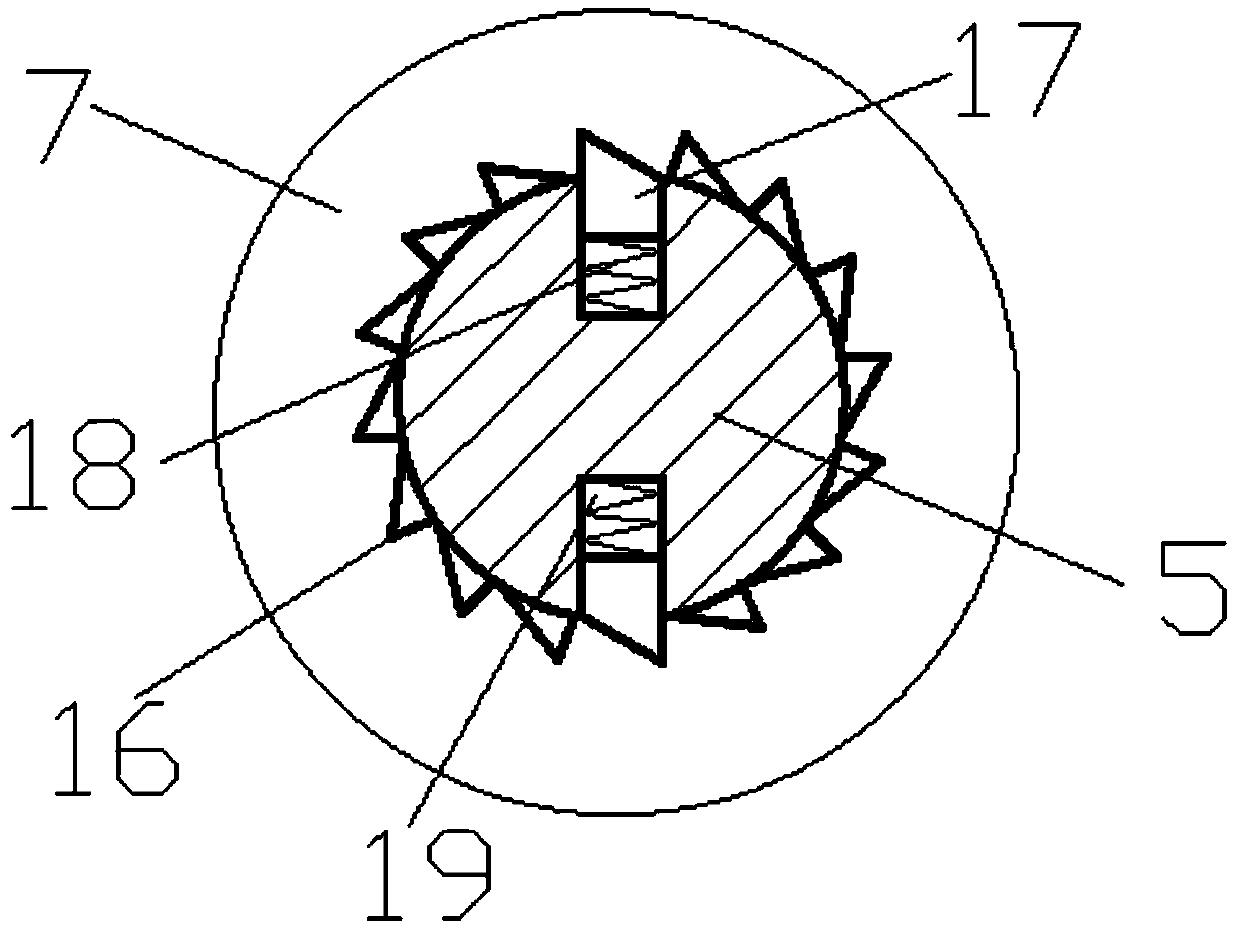

[0031] Such as Figure 1-5 As shown, a mechanical foam nail driver includes a housing 1 and a trigger 2. The housing 1 is provided with an accommodating chamber 3 and a nailing hole 4. One side of the upper end of the accommodating chamber 3 and the nailing hole 4 are One end is connected, and a rotating shaft 5 is arranged in the accommodation cavity 3, and a large gear 6 and a small gear 7 are arranged on the rotating shaft 5 in sequence. There are several identical gear faces 61 and several identical notches 62, and the notches 62 and the gear faces 61 are arranged with gaps. The large gear 6 is fixed on the rotating shaft 5, and the pinion 7 and the rotating shaft 5 can move in one direction at the same time through the action of the ratchet mechanism. One end of the push rod 9 is provided with a push rod 9, and the push rod 9 is axially provided with a rack 91, the rack 91 meshes with the gear surface 61, and the other end of the piston rod 8 is inserted into the nailing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com