Full-automatic adhesive tape sticking and packaging device for corrugated carton

A corrugated box, fully automatic technology, applied in the field of corrugated box automatic tape packaging device, can solve the problems of low work efficiency of corrugated boxes, many corrugated boxes, high labor intensity of workers, etc., to reduce labor intensity, reduce operation, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

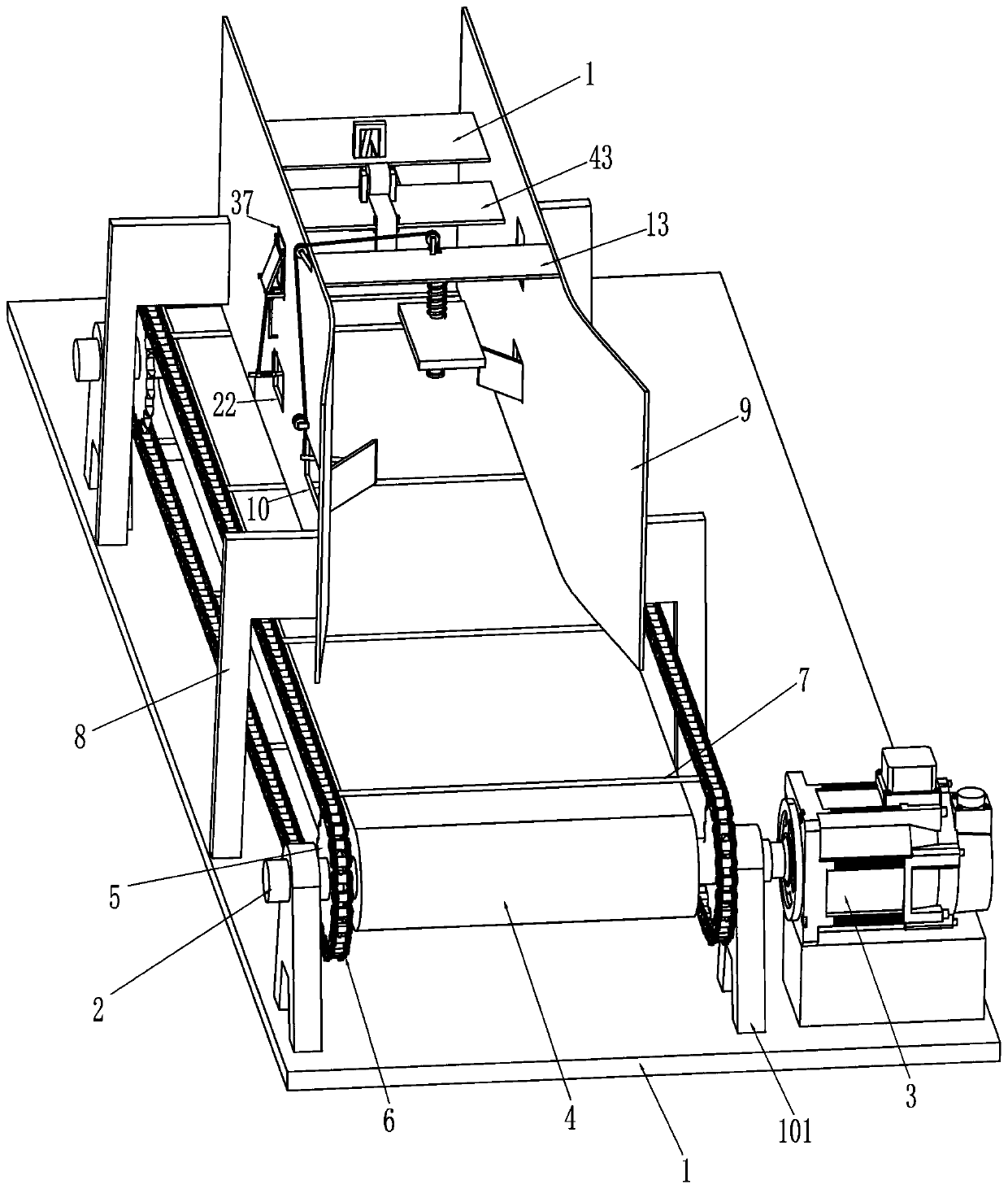

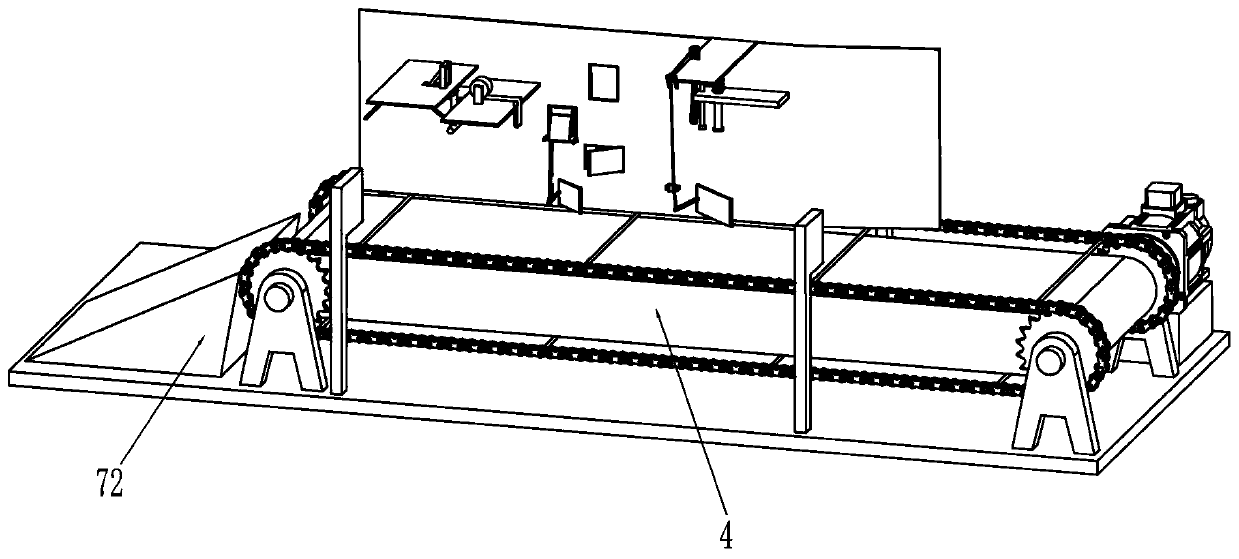

[0025] A full-automatic adhesive tape packaging device for corrugated boxes, such as Figure 1-2 As shown, it includes a bottom plate 1, a support seat 101, a rotating rod 2, a motor 3, a conveyor belt 4, a sprocket 5, a chain 6, a first push rod 7, a first support frame 8, a limit plate 9, and front and rear swing covers The closure component, the left and right flap closure component, the packaging component and the inclined block 72. The front and rear sides of the top of the bottom plate 1 are provided with two support seats 101 and a first support frame 8. The first support frames 8 on the front and rear sides are located on the front and rear sides. Between the support bases 101, the two support bases 101 on the front side are rotatably connected with the rotary rod 2, and the two support bases 101 on the rear side are also rotatably connected with the rotary rod 2. There is a conveyor belt 4 in between, a motor 3 is installed on the top of the bottom plate 1, and the outp...

Embodiment 2

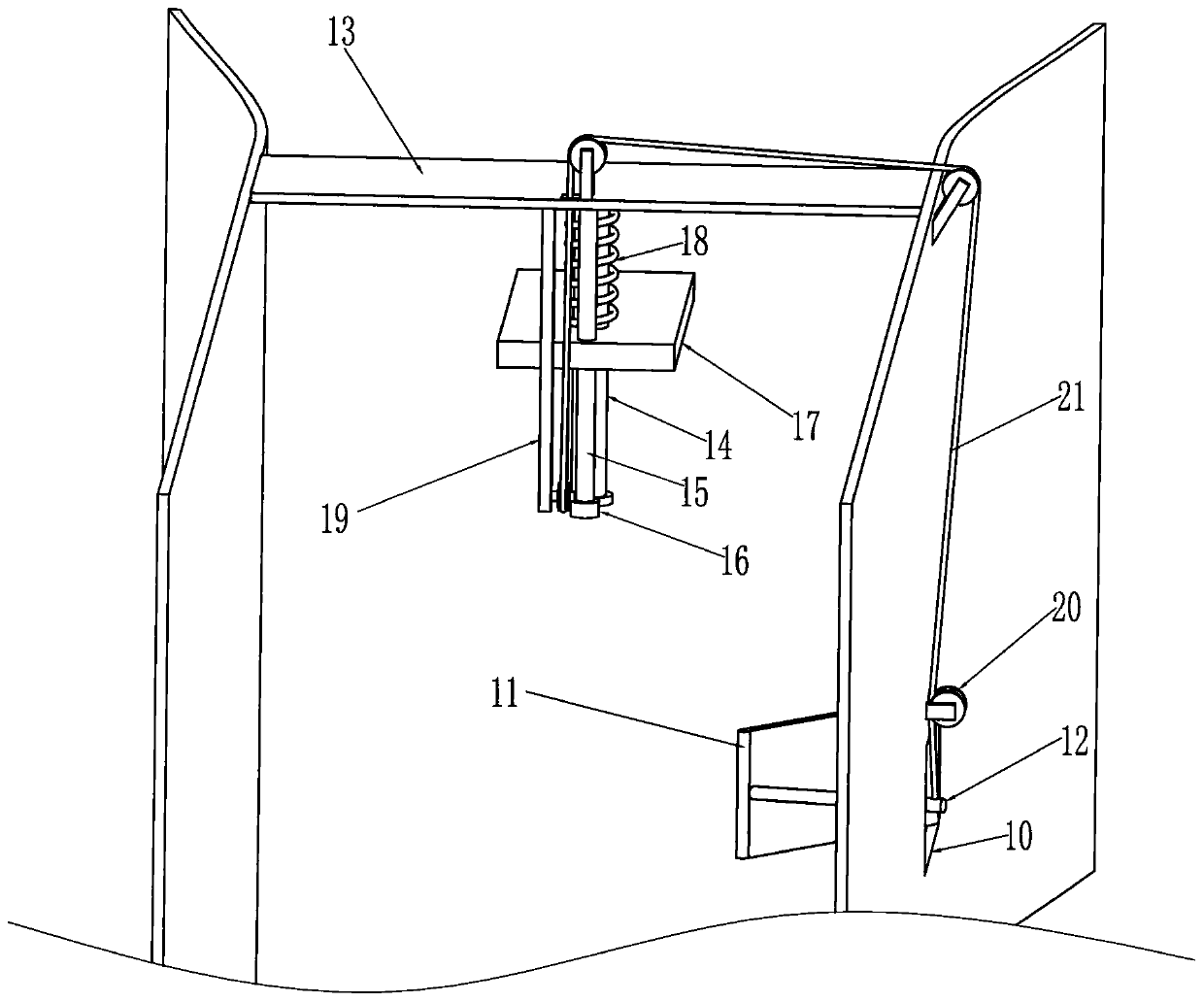

[0028] On the basis of Example 1, such as Figure 1-10 As shown, the front and rear swing cover closing assembly includes a first rotating plate 11, a fixed rod 12, a first supporting plate 13, a first sliding rod 14, a limiting rod 15, a first limiting block 16, a pressing plate 17, and a first spring 18. The first support rod 19, the guide wheel 20 and the draw rope 21, the left limit plate 9 has a first opening 10 in the front part, and the first opening 10 is rotatably provided with a first rotating plate 11, A fixed rod 12 is fixedly connected to the rotating plate 11, a first supporting plate 13 is arranged between the two limiting plates 9, and a first sliding rod 14 and a limiting rod 15 are arranged at the bottom of the first supporting plate 13. The first sliding rod 14 is located on the front side of the limit rod 15. The first sliding rod 14 and the bottom end of the limit rod 15 are both provided with a first limit block 16, and the pressure plate 17 is slidably ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com