Preparation method of heterogeneous stacked multilayer ceramic capacitor of antiferroelectric material system

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems that cannot be further improved, capacitor failure energy storage density, etc., to facilitate large-scale industrial production, improve breakdown strength and extreme Good chemical strength and production process compatibility

Active Publication Date: 2022-06-03

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the zirconium tin titanate lead lanthanum antiferroelectric material system has piezoelectric properties, and there is a certain strain during the charging and discharging process, which is the bottleneck problem that the capacitor fails and the energy storage density cannot be further improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

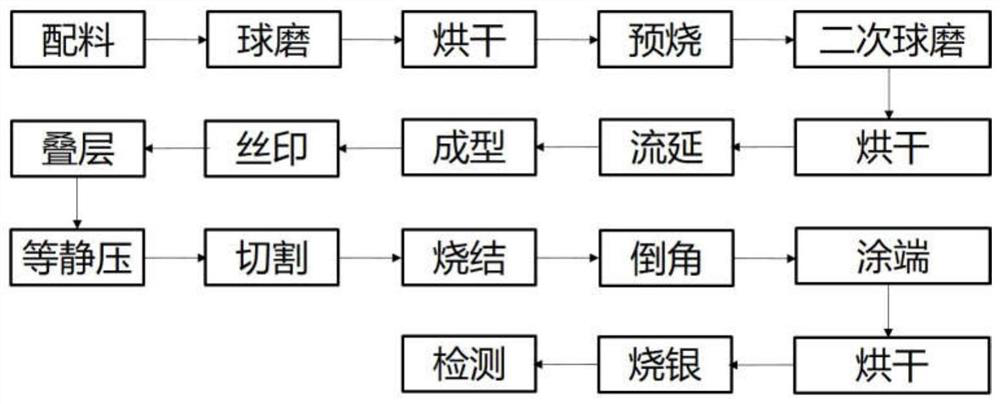

The invention discloses a method for preparing a heterogeneous stacked multilayer ceramic capacitor based on an antiferroelectric material system, which belongs to the technical field of electronic information materials and components. First, according to Pb respectively (1‑1.5x) La x Zr (1‑y1‑z1) sn y1 Ti z1 o 3 and Pb (1‑1.5x) La x Zr (1‑y2‑z2) sn y2 Ti z2 o 3 Structural formula, weighing and mixing, to obtain powders A and B; then, powder A and powder B were ball milled, dried, pre-calcined, secondary ball milled, and cast to obtain monolayer film A and monolayer Film B: Composite single-layer film A and single-layer film B according to the "AB" or "ABA" method as the dielectric layer, and screen-print metal as the electrode layer to prepare a multilayer ceramic capacitor. The multilayer ceramic capacitor obtained by the invention has an interface enhancement effect, can effectively improve the breakdown strength and polarization strength, and further increase the energy storage density of the capacitor.

Description

Preparation method of heterogeneous stacked multilayer ceramic capacitor of antiferroelectric material system technical field The invention belongs to the technical field of electronic information materials and components, and is specifically related to a kind of antiferroelectric material of heterogeneous stacking A preparation method of a material system multilayer ceramic capacitor. Background technique [0002] Pulse power capacitors play an important role in electromagnetic guns, laser ignition, and deep well detection. With the Section With the development of technology, the trend of miniaturization and high power has become more and more significant, especially for shipboard, vehicle, airborne and even satellite Loaded pulse power system, put forward higher and more specific requirements. The traditional zirconium tin titanate lanthanum lead system, due to having a high stubborn field, a higher polarization intensity, the energy storage density can reach To 4...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/491C04B35/622C04B41/88H01G4/12H01G4/30

CPCC04B35/491C04B35/622C04B41/88C04B41/5116H01G4/1245H01G4/30C04B2235/3227C04B2235/3293C04B2235/6567C04B41/4539C04B41/0072

Inventor 魏猛张继华陈宏伟高丽彬

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com