Oilfield oil extraction sampling device and operation method

A sampling device and oilfield technology, applied in the direction of production fluid, earthwork drilling, mechanical equipment, etc., can solve the problems of increasing difficulty in disassembly, reducing detection efficiency, affecting detection, etc., to ensure cleaning ability, strong controllability, increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

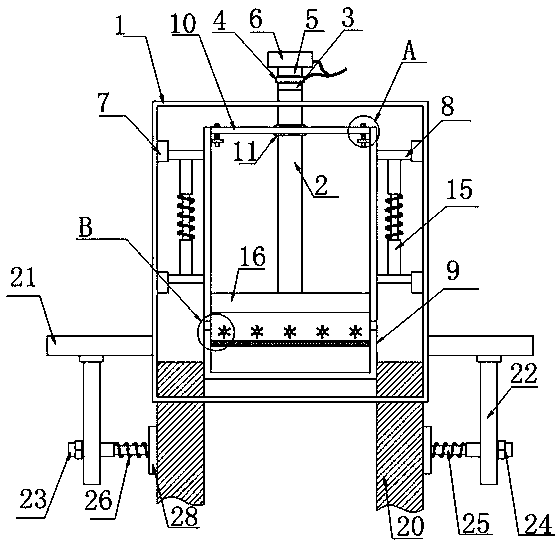

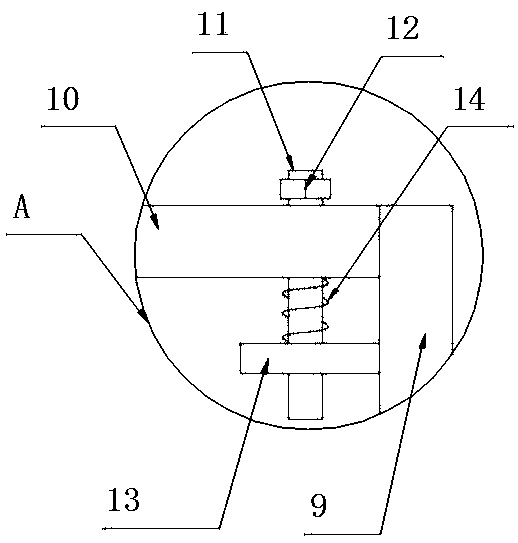

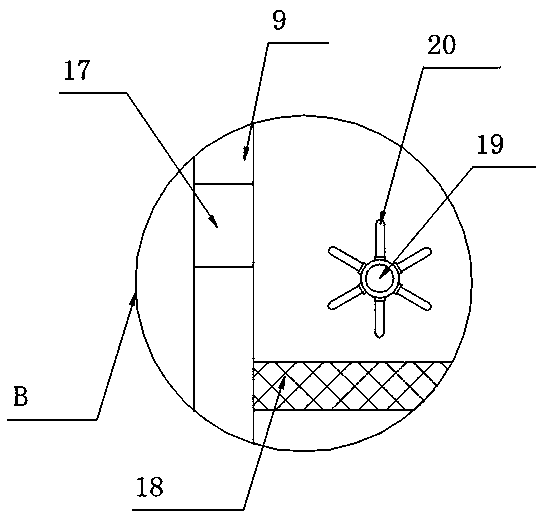

[0041] The specific embodiment is: utilize controller 27 to start electromagnet 4 and air pump 6, make electromagnet 4 produce magnetic force to attract magnet 3, now air pump 6 lifts piston rod 2 and rises, thereby increased the space at the bottom of piston 16, realized to sample The internal air pressure of the inner sleeve 9 increases, so that the crude oil inside the scraper 20 at the bottom of the sampling circular sleeve 1 is extracted, and the magnetic force generated by the electromagnet 4 is more stable and controllable; The installation between the sampling inner cylinder sleeve 9 and the sampling circular sleeve 1 is stable, and at the same time, the setting of the stabilizing component 15 reduces the overall difficulty and avoids the problem of uneven sampling caused by the vibration generated by the pneumatic rod 5 during the sampling process, which greatly increase the safety of the device; stop the controller 27, so that the controller 27 stops the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com