Low-energy-consumption catalytic combustion device

A catalytic combustion and low-temperature combustion technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of one-way removal of VOC, difficult operation, single function, etc., achieve high VOC purification efficiency and reduce energy consumption , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

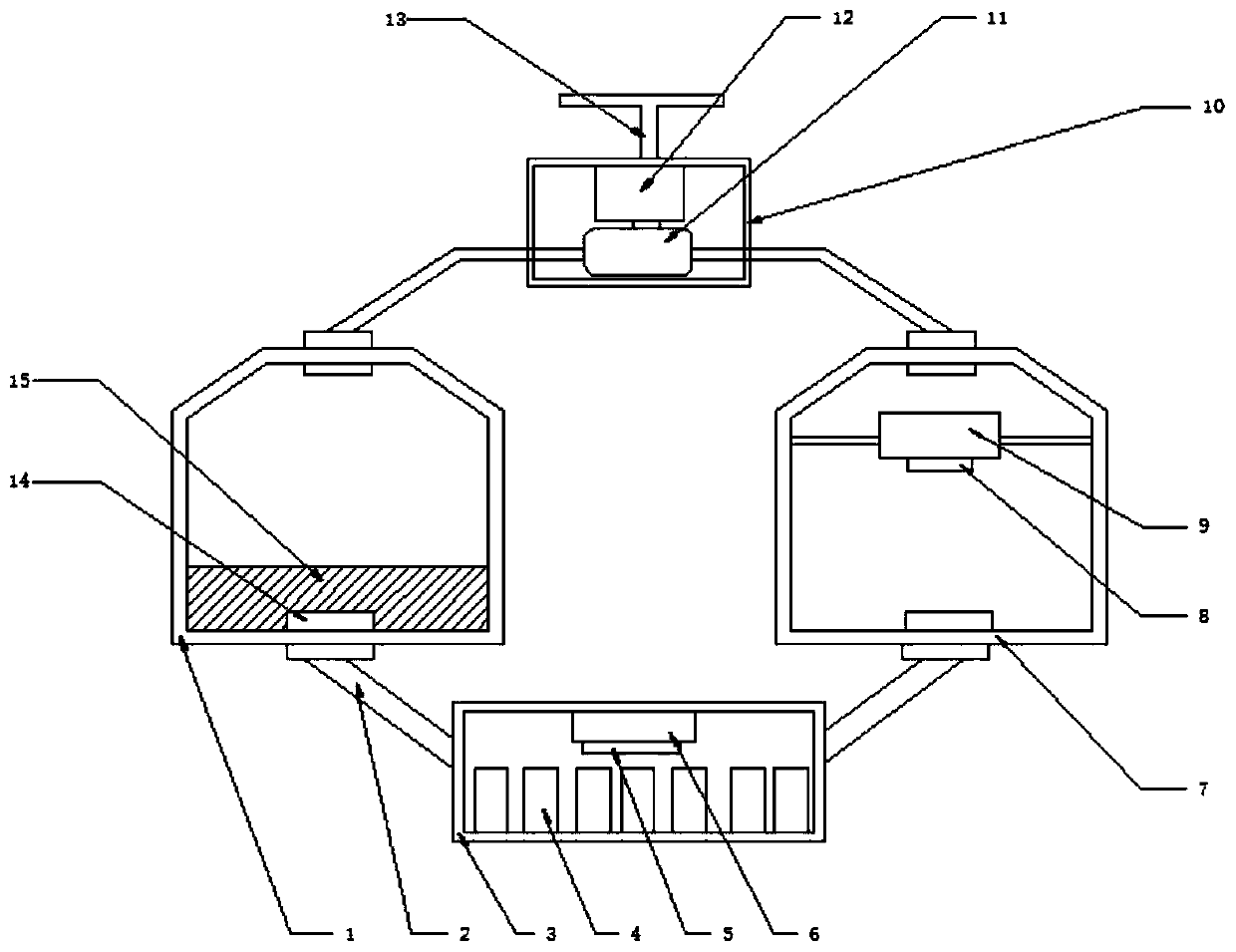

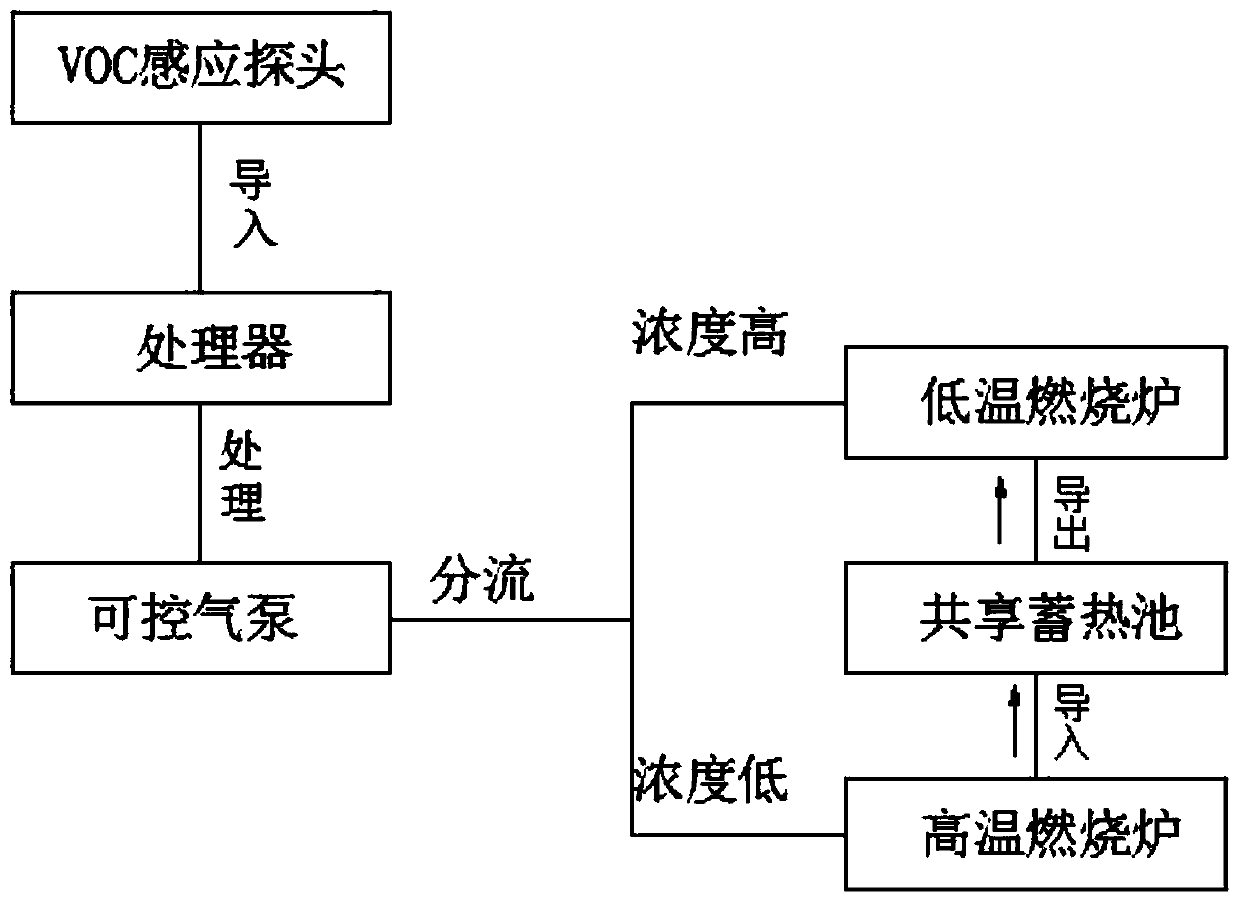

[0023] Such as figure 1 , figure 2 As shown, a catalytic combustion equipment with low energy consumption, including a high-temperature combustion furnace, a low-temperature combustion furnace, a VOC introduction device and a shared heat storage tank;

[0024] The VOC introduction device is connected to the high-temperature combustion furnace and the low-temperature combustion furnace, and the VOC introduction device is used to introduce VOC into the high-temperature combustion furnace or the low-temperature combustion furnace;

[0025] The shared heat storage pool is connected to the high-temperature combustion furnace and the low-temperature combustion furnace, and the shared heat storage pool is used to conduct heat to the high-temperature combustion furnace and the low-temperature combustion furnace to support heat supplementation.

[0026] Preferably, the high-temperature combustion furnace includes a heating combustion chamber 1, a heating chassis 15 and a switching va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com