Ultra-fast laser micro trimming system of sensitive functional parts of resonant inertial device

A technology of inertial devices and ultrafast lasers, which is applied to instruments, measuring devices, and navigation through speed/acceleration measurements, can solve the problems of poor accuracy of trimming and deduplication and low trimming efficiency, and achieve simple trimming steps, Realize the effect of adjusting positioning accuracy and avoiding workpiece assembly and positioning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

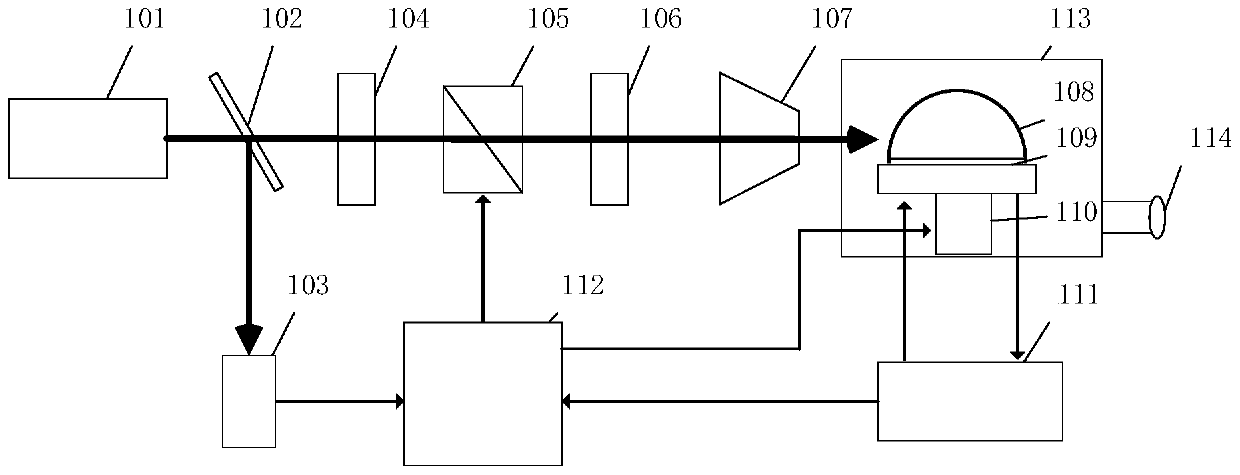

[0031] The invention discloses an ultrafast laser micro-adjustment system for sensitive functional components of a resonant inertial device, and belongs to the technical field of resonant inertial device manufacturing. The ultrafast laser micro-adjustment system for sensitive functional components of resonant inertial devices disclosed in the present invention includes an ultrafast laser, a beam splitter, a photoelectric detector, a polarizer, an electro-optical modulator, an analyzer, a laser processing head, an excitation And detection tooling, multi-axis motion platform, frequency cracking analyzer, industrial computer, vacuum chamber and vacuum pump.

[0032] Real-time excitation and detection of inertial characteristic changes of the workpiece to be repaired by the frequency cracking analyzer, feedback and control of ultra-fast laser sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com