A kind of synthesis method of nitrogen-doped molybdenum selenide, nitrogen-doped molybdenum selenide and its application

A synthesis method and molybdenum selenide technology are applied in the synthesis of nitrogen-doped molybdenum selenide, nitrogen-doped molybdenum selenide and its application fields, and can solve the problems of material surface collapse, excessive potassium ion radius and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A kind of synthetic method of nitrogen-doped molybdenum selenide, it comprises the following steps:

[0020] First object of the present invention is to provide a kind of synthetic method of nitrogen-doped molybdenum selenide, it comprises the following steps:

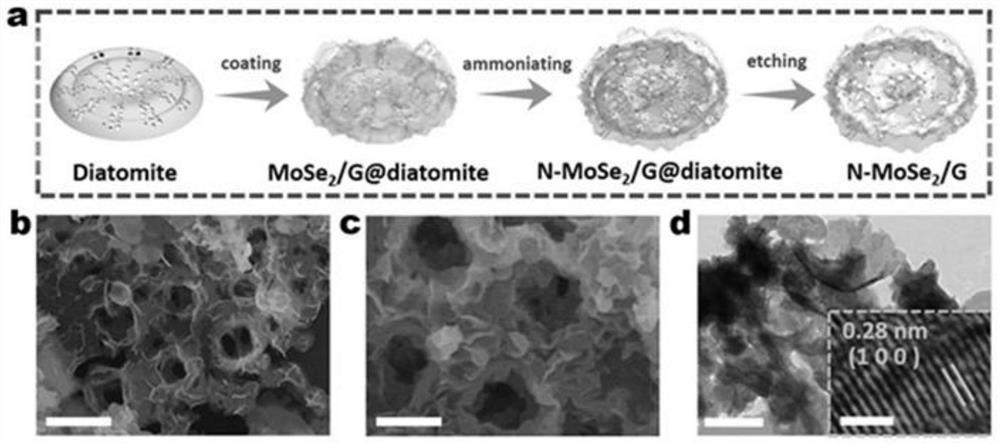

[0021] (a) dissolving selenium powder in reducing agent hydrazine hydrate to obtain a first solution, dissolving sodium molybdate, biomass template diatomaceous earth and GO powder in water to obtain a second solution, mixing the first solution and the second solution uniformly, Put it into a hydrothermal kettle and conduct a hydrothermal reaction at 180-220°C for 8-12 hours to obtain the third solution; the mass ratio of the total mass of selenium powder and sodium molybdate to diatomite is 1:1-4. The mass ratio of selenium powder to sodium molybdate is 1:1-2.

[0022] (b) The third solution is centrifuged and dried to obtain a molybdenum selenide / graphene mixed powder, and the molybdenum selenide / graphene mix...

Embodiment 1

[0033] Embodiment 1 provides a kind of synthetic method of nitrogen-doped molybdenum selenide, and it comprises the following steps:

[0034] (a) Dissolve 0.622g of selenium powder in 20ml of hydrazine hydrate, stir vigorously for 12h to obtain the first solution, dissolve 0.953g of sodium molybdate powder and 2.5g of biomass template diatomite in 300ml of water and stir evenly, then add 50ml of GO aqueous solution (4mg.mL -1 ) to obtain the second solution, mix the first solution and the second solution evenly, put them into a 200° C. hydrothermal kettle for 10 h to obtain the third solution.

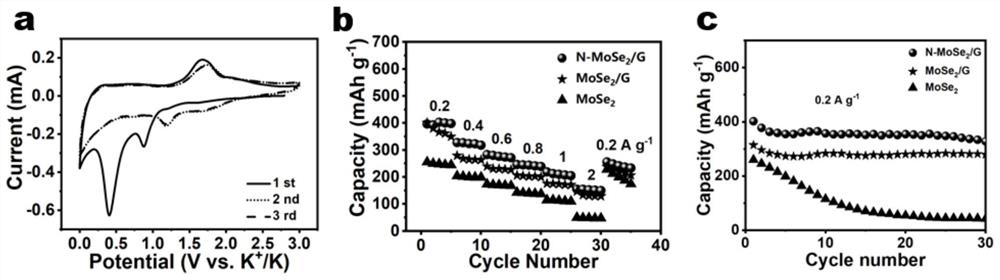

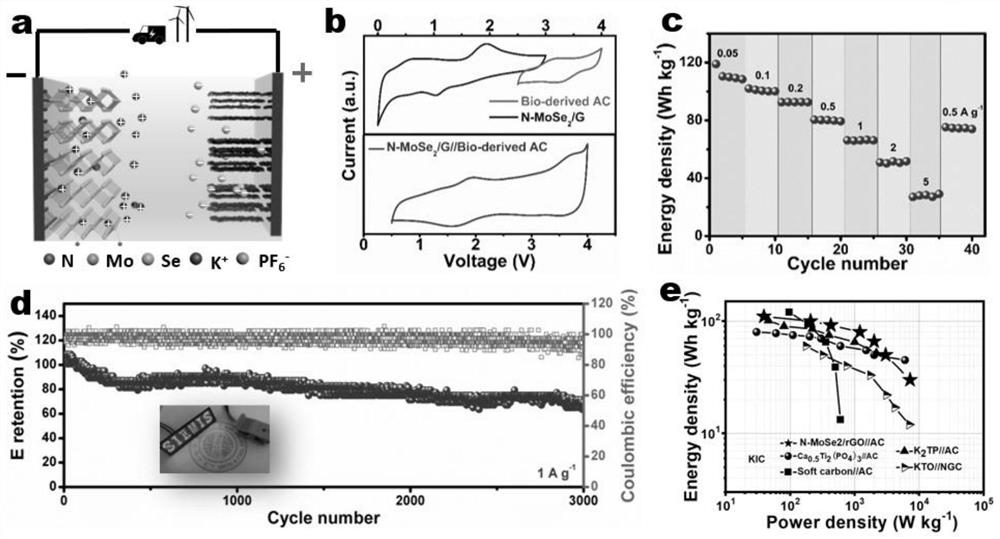

[0035] (b) the third solution is centrifuged, washed, and dried to obtain molybdenum selenide powder, which is placed in an ammonia atmosphere and annealed min heating rate to 500°C for 2 h), and then etched the calcined powder with hydrofluoric acid to obtain nitrogen-doped molybdenum selenide N-MoSe with a three-dimensional network structure and replicating template morphology 2 / G...

Embodiment 2

[0042] Embodiment 2 provides a kind of synthetic method of nitrogen-doped molybdenum selenide, nitrogen-doped molybdenum selenide and application thereof, it is basically consistent with Example 1, the difference is only: in step (a), the addition of sodium molybdate powder The amount is 0.622g.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap