Sweet potato powder stirring machine

A technology of mixer and sweet potato flour, applied in mixer accessories, mixers, mixers with rotating containers, etc., can solve the problems of mixing dead corners, difficult to fully mix materials, poor mixing effect, etc., to improve the effect and avoid material scattering leakage, the effect of improving sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

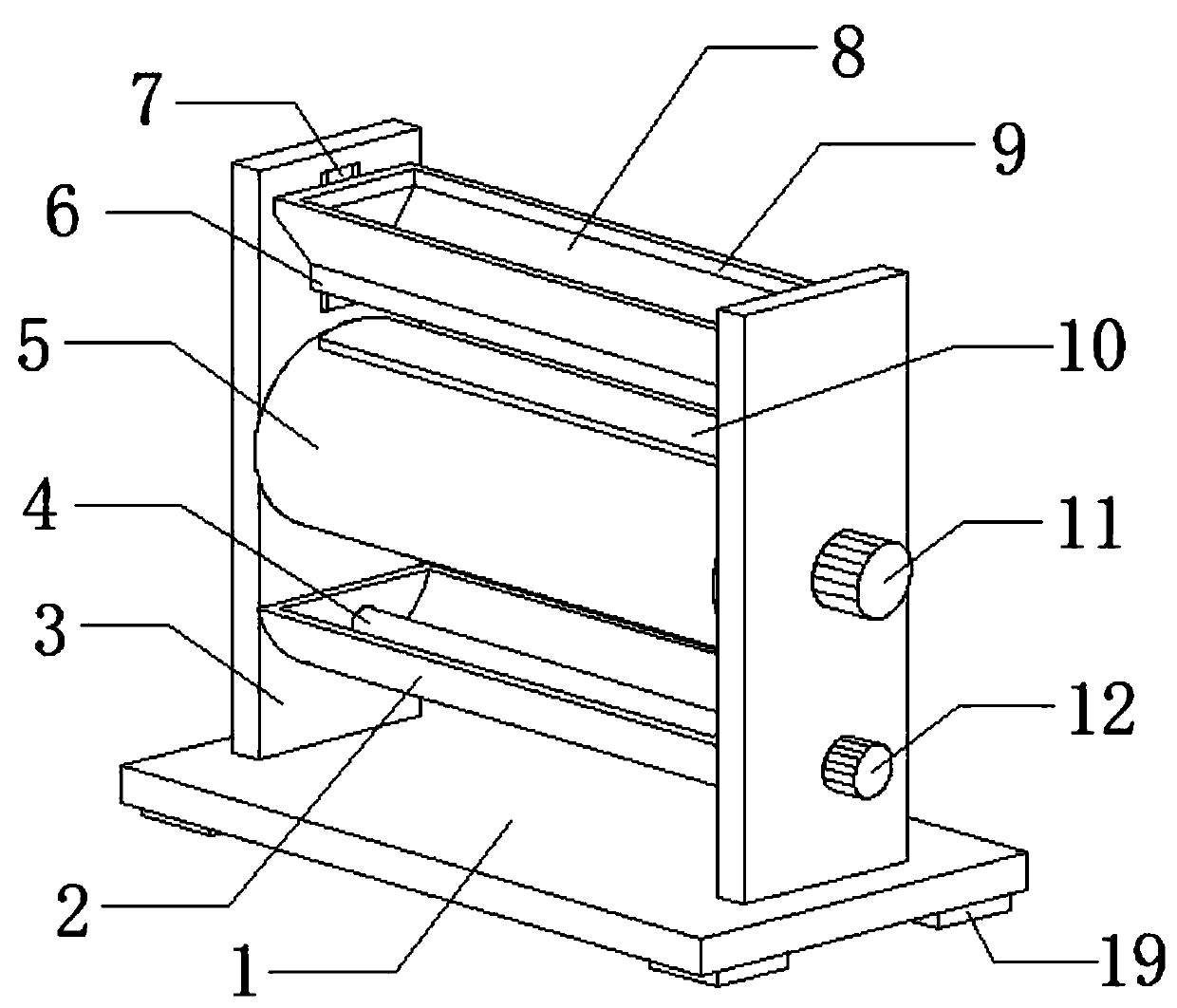

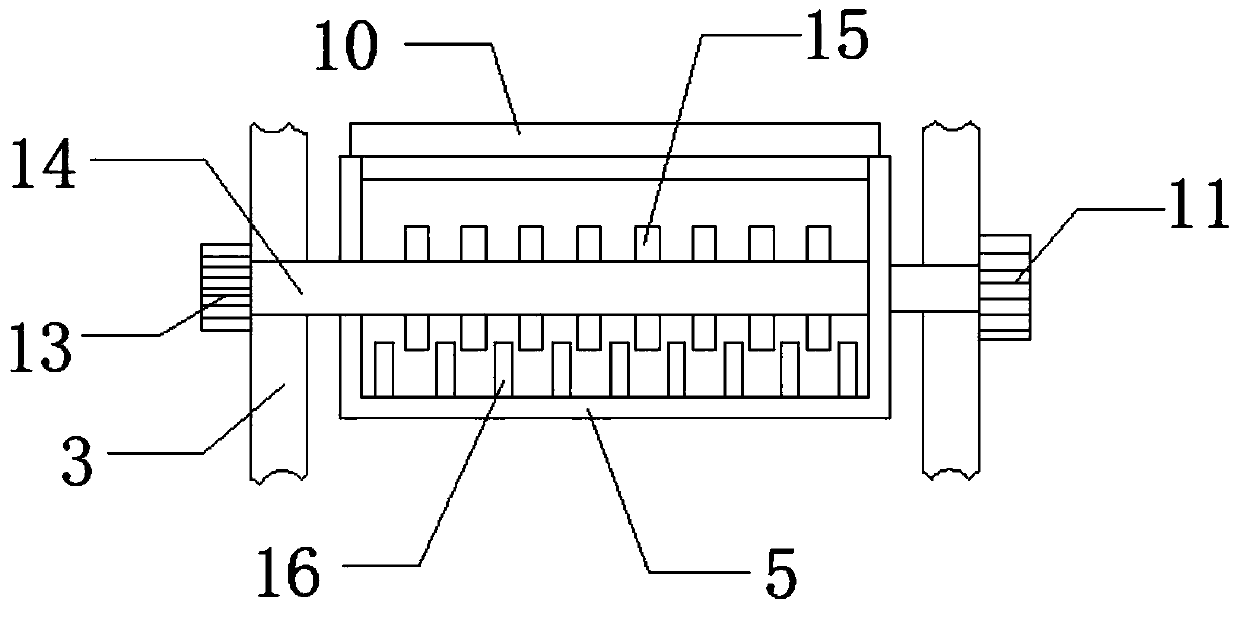

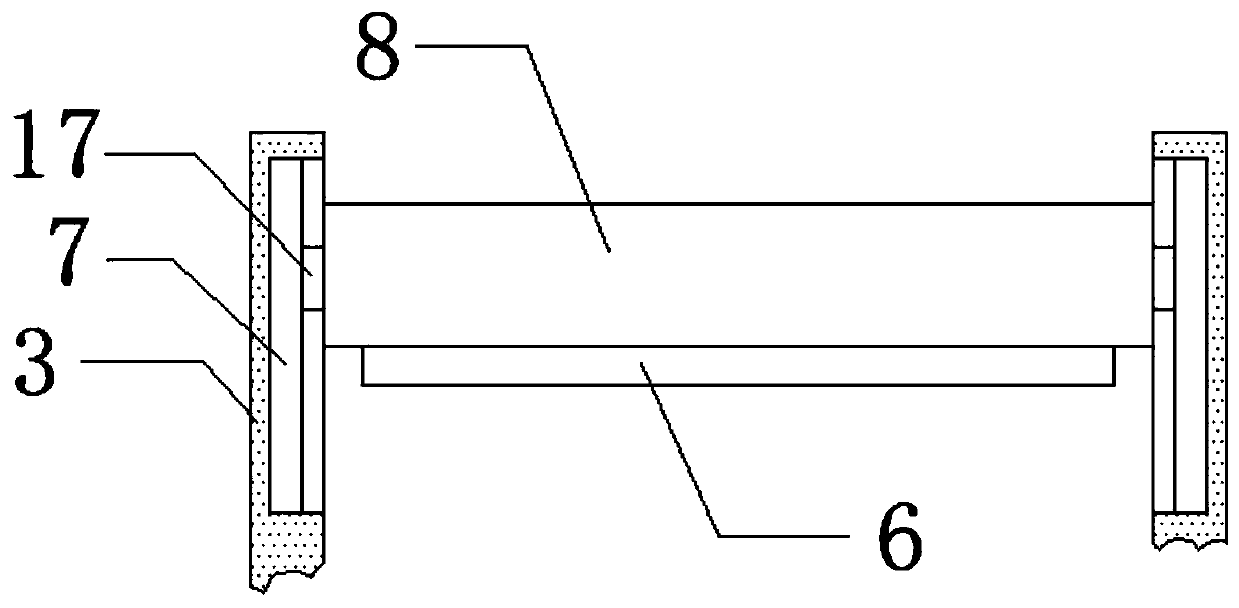

[0030] A sweet potato flour blender such as Figure 1-4 As shown, it includes a support base 1 and two first support plates 3, and the bottom outer walls of the two first support plates 3 are respectively installed on the two side outer walls of the top of the support base 1 by bolts, and one of the first support plates 3 on one side The outer wall of the middle part is connected with the first rotating motor 11 by bolts, and the output shaft of the first rotating motor 11 is connected with the stirring box 5 by bolts, and the outer wall of the middle part of one side of the other first support plate 3 is connected with the third rotating motor by bolts 13, and the output shaft of the third rotating motor 13 is connected with the second rotating rod 14 by bolts, and the circumference top and the bottom outer wall of the second rotating rod 14 are connected with the stirring rods 15 equidistantly arranged by bolts, and the stirring box 5 The inner wall of the bottom is connecte...

Embodiment 2

[0035] A sweet potato flour blender such as figure 1 , 3 , 4 and 5, it also includes an installation groove opened on the outer wall of one end of the second rotating rod 14, and the inner wall of the installation groove is connected with a heater 20 by bolts.

[0036] When this embodiment is in use, the user can start the heater 20, and the heater 20 will effectively dry the sweet potato powder, avoiding the sweet potato powder from damp and agglomerating, and further improving the stirring and mixing effect of the sweet potato powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com