Chlorohydrination reaction device for producing epoxide by using chlorohydrination method, and use method thereof

A reaction device, epoxide technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problem of large amount of saponification wastewater and low production efficiency , equipment investment and other problems, to achieve the effect of increasing chlorohydrin concentration, large production capacity and high chlorohydrin concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

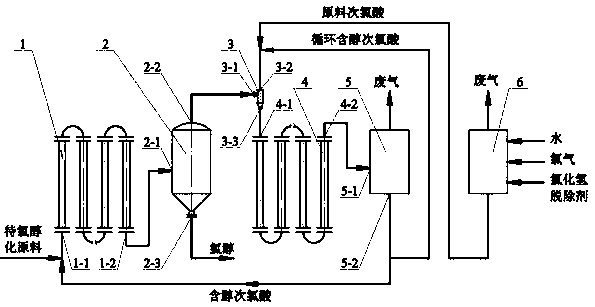

[0027] The chlorohydrination reaction device for the production of epoxides by the chlorohydrin method in this embodiment comprises: a main chlorohydrination reactor 1, a gas-liquid separator 2, an injector 3, a secondary chlorohydrination reactor 4, an alcohol-containing hypochlorous acid tank 5, a secondary Chloric acid reaction device 6, connecting pipelines between equipment, valves, medium conveying devices, control and display instruments and accessories. The main chlorohydrinization reactor 1 and the secondary chlorohydrinization reactor 4 are tubular reactors in which spoiler elements are continuously installed, and the spoiler elements are chemical fillers; the main chlorohydrinization reactor 1 is equipped with raw materials for chlorohydrinization and alcohol-containing hypochlorite Acid inlet 1-1 and reactant outlet 1-2, gas-liquid separator 2 is provided with the reactant inlet 2-1 to be separated and gas outlet 2-2 and chlorohydrin outlet 2-3 from the chlorohydrin...

Embodiment 2

[0030] Embodiment 2 is basically the same as Embodiment 1, except that the main chlorohydrination reactor 1 and the secondary chlorohydrination reactor 4 and the turbulence elements in them are static mixers.

Embodiment 3

[0032] Example 3 is basically the same as Example 1, except that the main chlorohydrination reactor 1 and the secondary chlorohydrination reactor 4 used are microchannel reactors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com