Preparation method of efficient biforous g-C3N4 photocatalyst

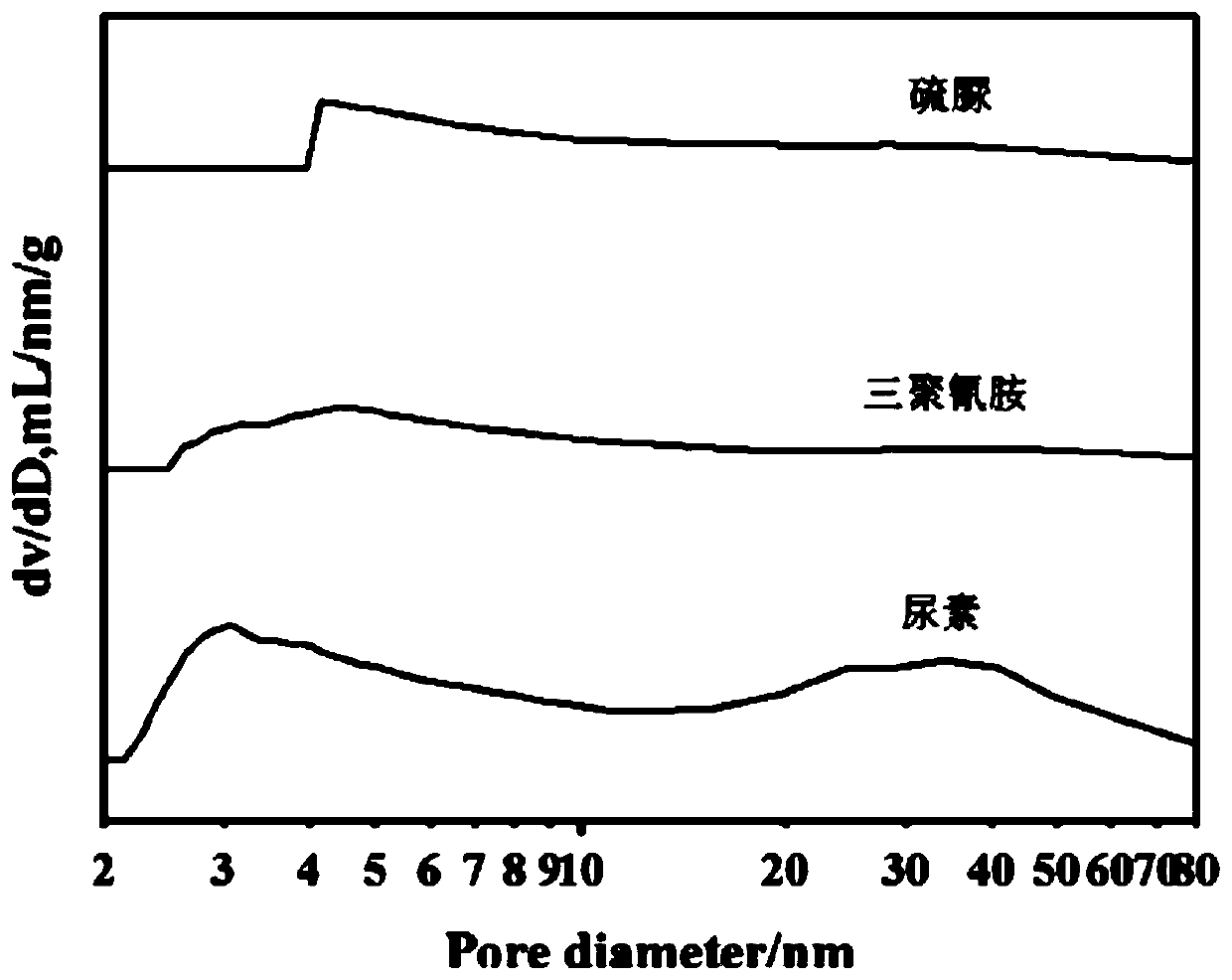

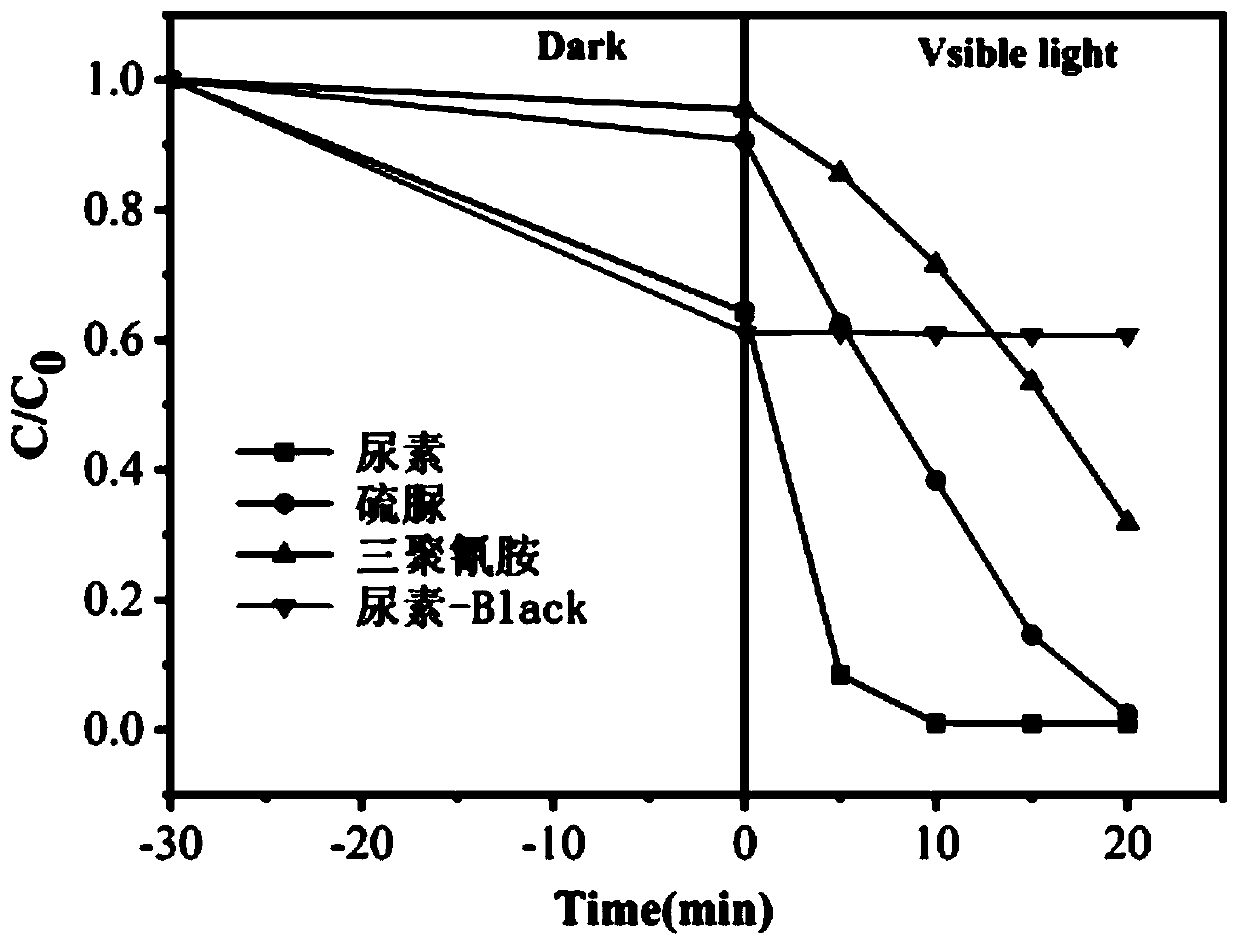

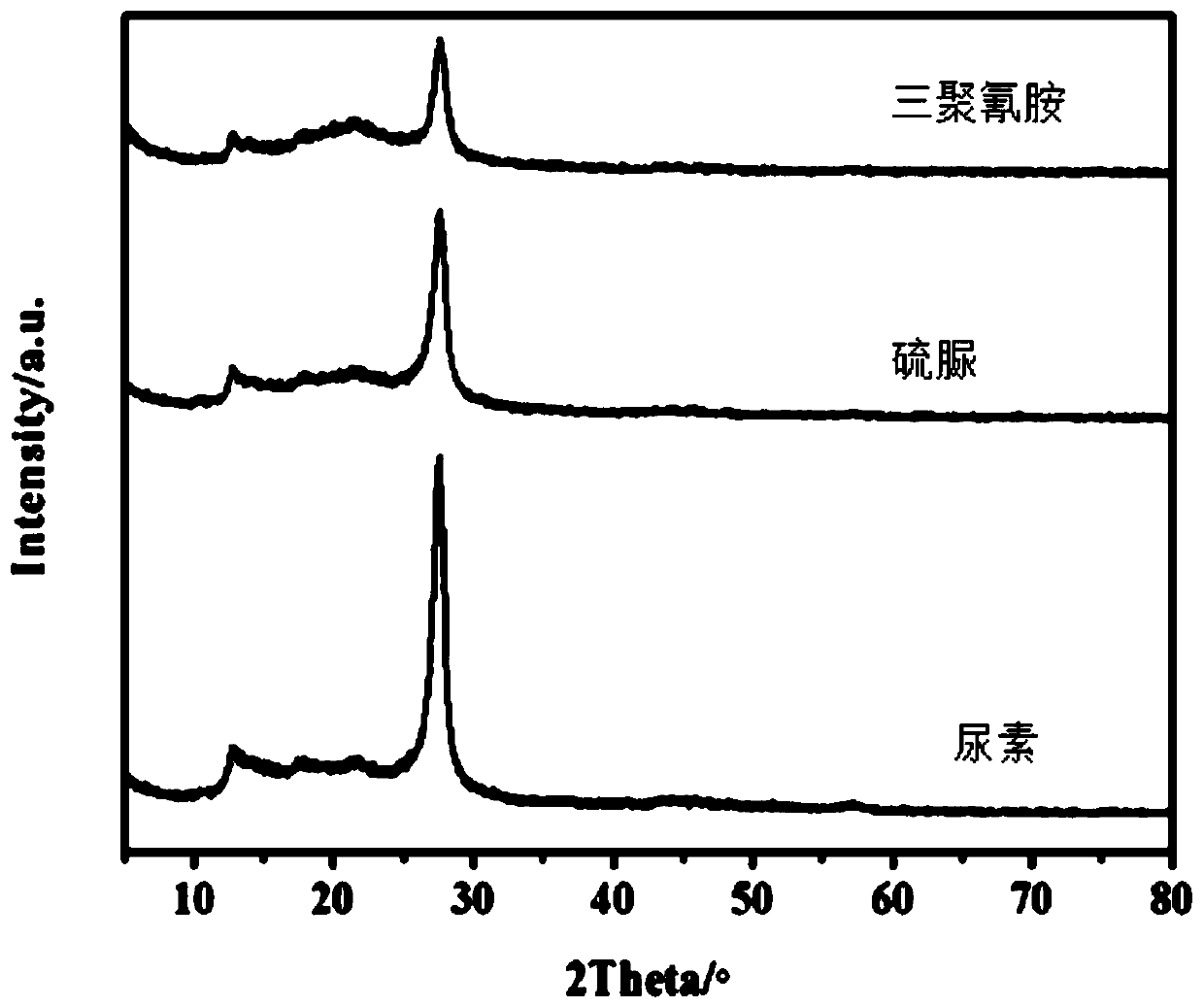

A photocatalyst, g-c3n4 technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor mass transfer, small specific surface area, and low photocatalytic activity, and achieve Effects of separation promotion, high photocatalytic activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 50g of urea and place it in a crusher, crush it into powder at a speed of 10000r / min, spread the urea powder through a 40-mesh sieve in a square crucible with a thickness of 1mm, put the crucible in a muffle furnace, Starting from room temperature, the temperature is raised to 450°C at a rate of 1°C / min, that is, the heating rate is 1°C / min, kept at 450°C for 1 hour, and cooled naturally to obtain a light yellow solid powder g-C 3 N 4 , denoted as CN-1.

Embodiment 2

[0032] The preparation method of this example is the same as that of Example 1, except that the rotating speed of the crusher in Example 1 is changed to 26000r / min, and the prepared catalyst is designated as CN-2.

Embodiment 3

[0034] The preparation method of this example is the same as that of Example 1, except that the sieve of Example 1 is changed to 120 mesh, and the prepared catalyst is designated as CN-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap