Material conveying mechanism

A conveying mechanism and material technology, which is applied in the direction of feed, grain processing, food science, etc., can solve the problems of unsatisfactory cutting effect, small clamping force of nip roller, and affecting work efficiency, so as to ensure normal automatic feeding and improve use Longevity and the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

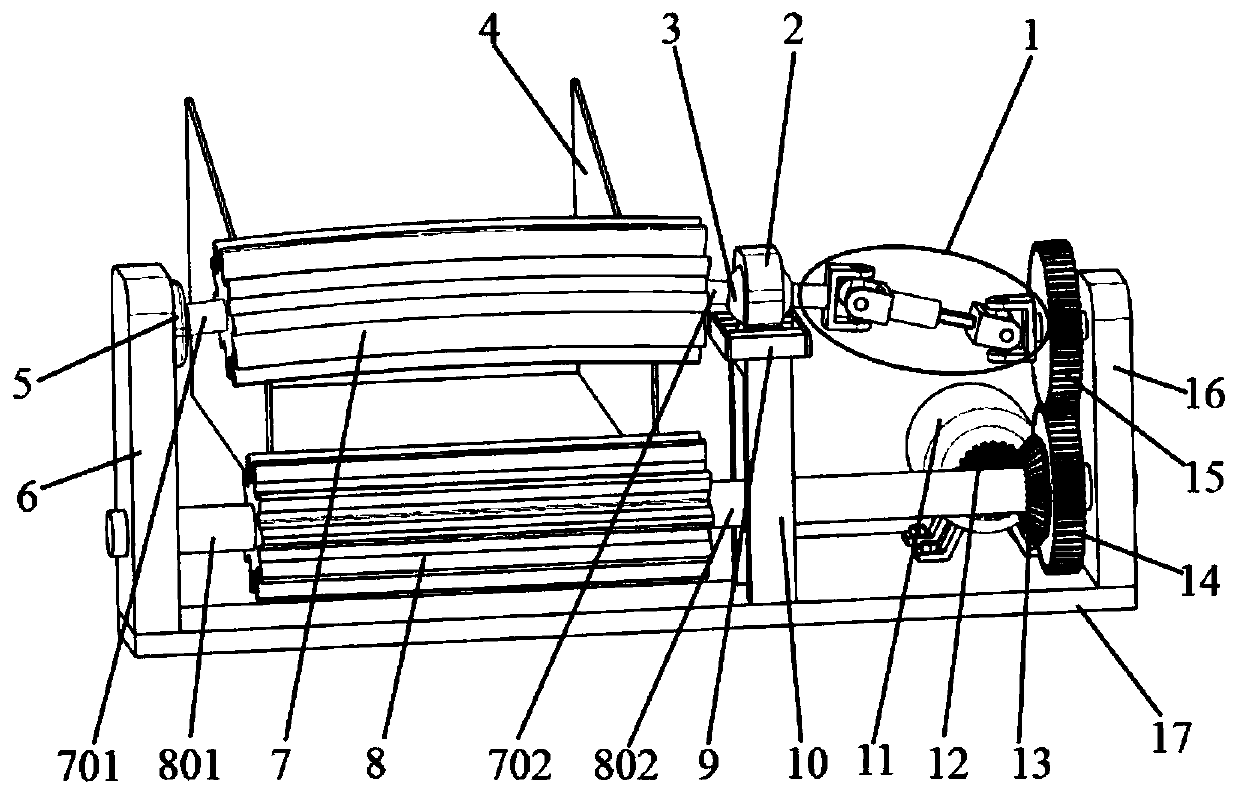

[0027] Such as figure 1 , figure 2 As shown, a material conveying mechanism includes a pinch roller, a transmission mechanism and a motor 11 .

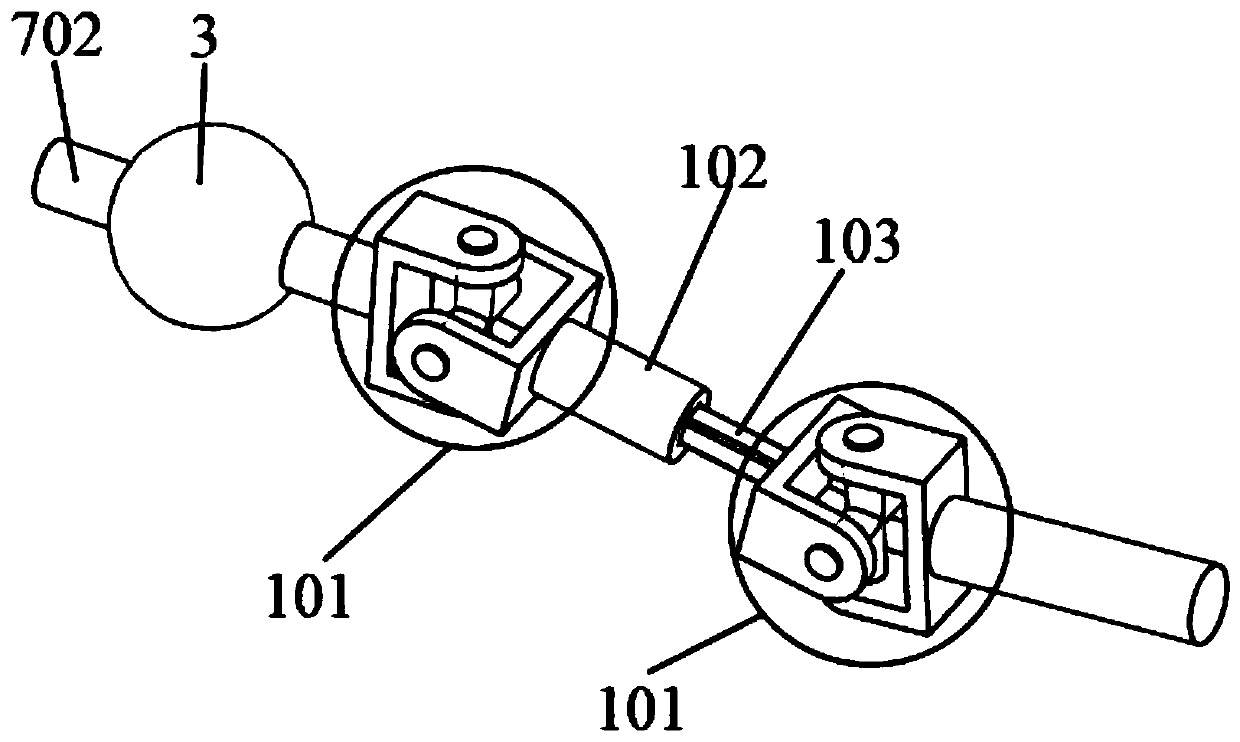

[0028] Described nip roller comprises the upper nip roller 7 and the lower nip roller 8 that are arranged vertically and are parallel to each other, the two ends of lower nip roller 8 are provided with lower nip roller left shaft 801 and lower nip roller right shaft 802, lower nip roller left shaft 801 and the right shaft 802 of the lower nip roller are movably connected on the equipment. The material of the upper nip roller 7 is rubber and has elasticity. The left shaft 701 of the roller is movably connected to the equipment through the ball hinge seat 5, and the right shaft 702 of the upper nip roller is fixedly connected with the ball 3. The ball 3 is arranged in the slider 2 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com