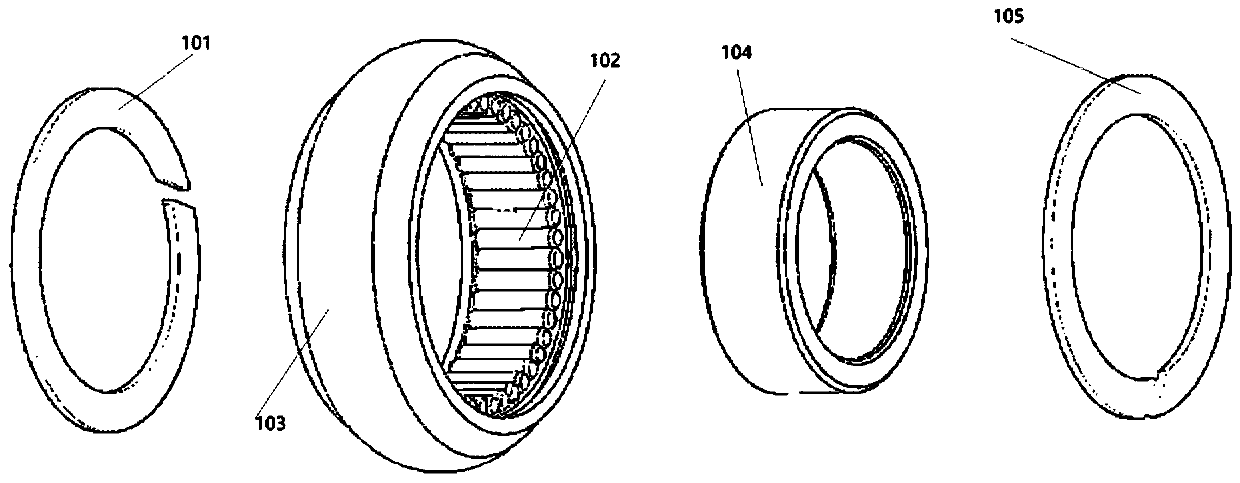

Full-automatic assembling device for outer ring double-flange needle bearing

A technology for assembly equipment and needle roller bearings, which is applied in the field of bearing assembly, can solve the problems of needle rolling, low efficiency of manual assembly, safety accidents, etc., and achieve the effects of increasing reliability, saving space and labor costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawing:

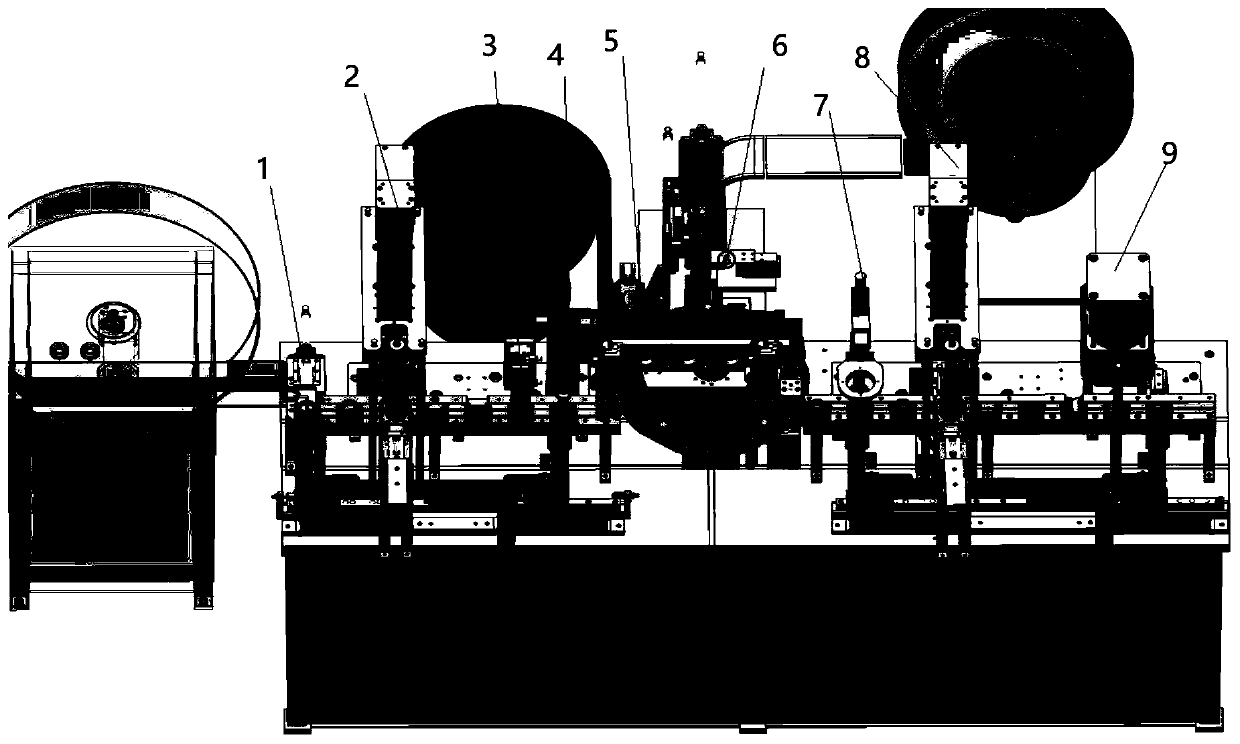

[0020] Embodiment: As shown in the accompanying drawings, the fully automatic assembly equipment for needle roller bearings with double ribs on the outer ring mainly includes station 1 for the upper outer ring, station A2 for pressing the needle retaining ring, station for flipping Station 3, Grease station 4, Inner ring pressing station 5, Needle roller installation station 6, Needle roller quantity detection station 7, Needle retaining ring pressing station B8, Secondary needle roller retaining ring station 9 , in the upper outer ring station 1, the guide block 12 is arranged at the rear of the centrifugal disc to guide the outer ring 103 that the centrifugal disc is sent into, and the cylinder 10 is arranged on one side of the guide block 12, and the shift fork 11 is arranged on the opposite side of the cylinder 10. The centrifugal disk pushes the outer ring 103 onto t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com