Device for smoothing and deburring plate surface

It is a technology for smooth surface and plate, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc. It can solve the problems of small grinding range and low efficiency of wood grinding, and achieve the effect of improving the leveling effect and stabilizing the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

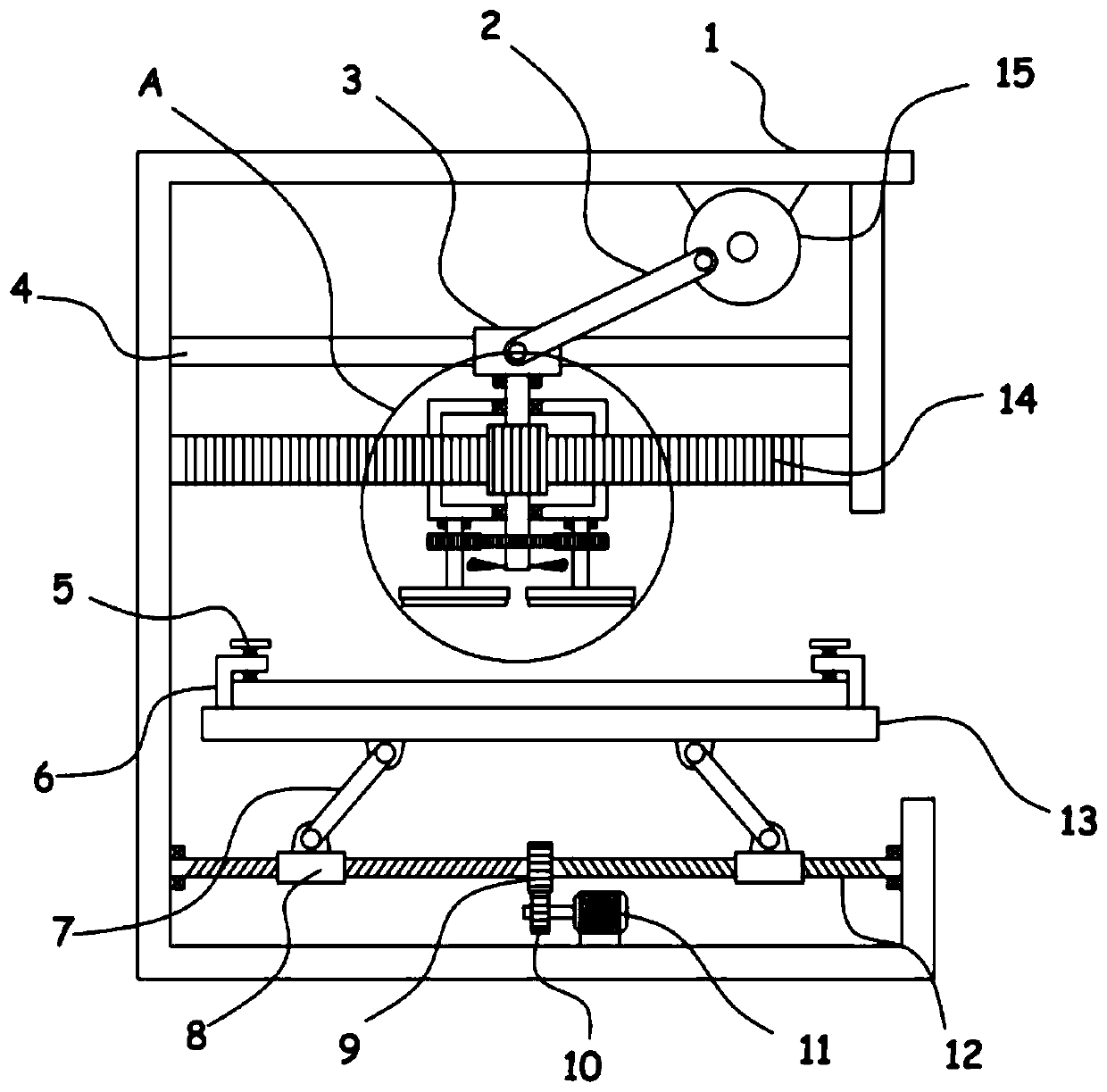

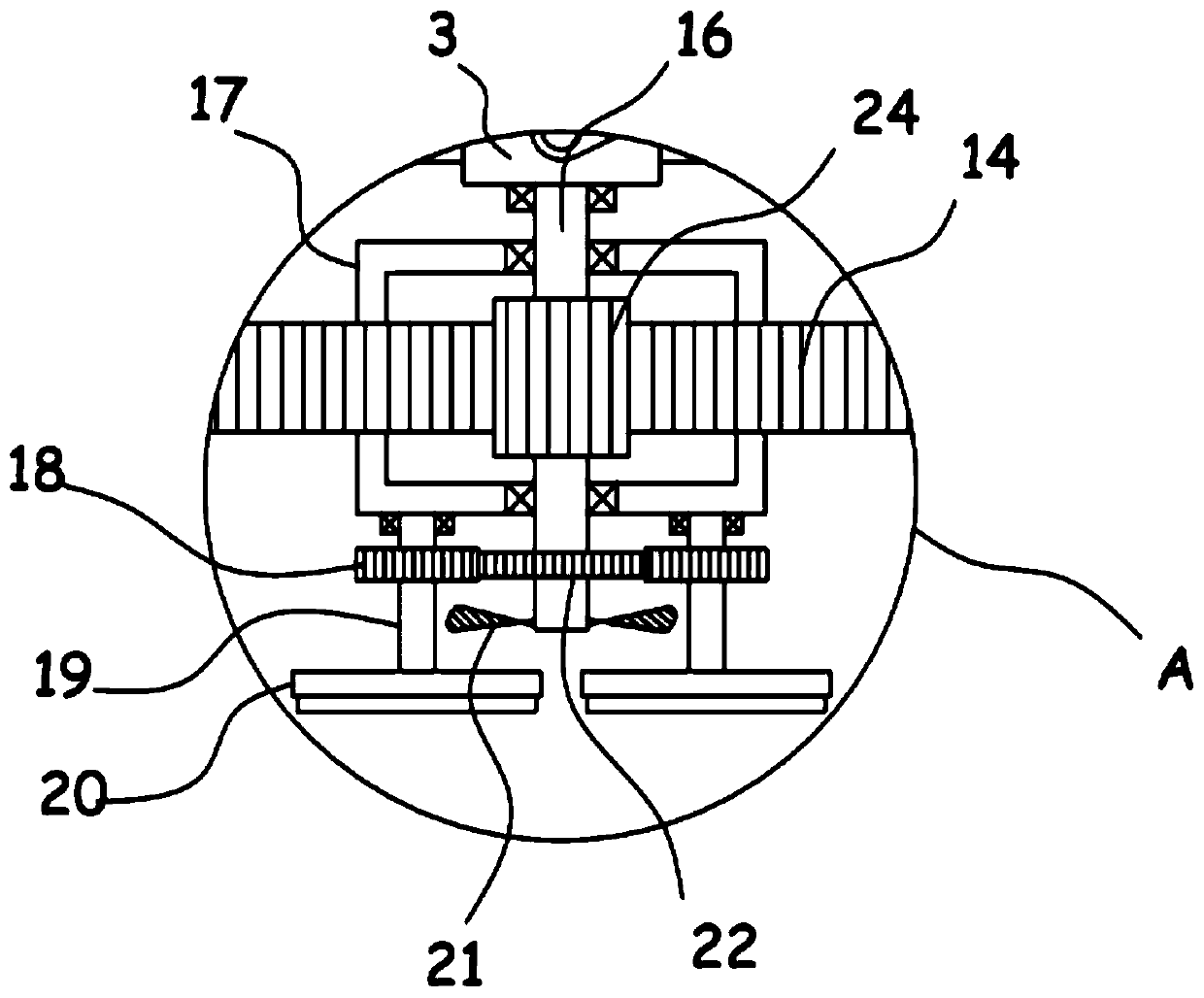

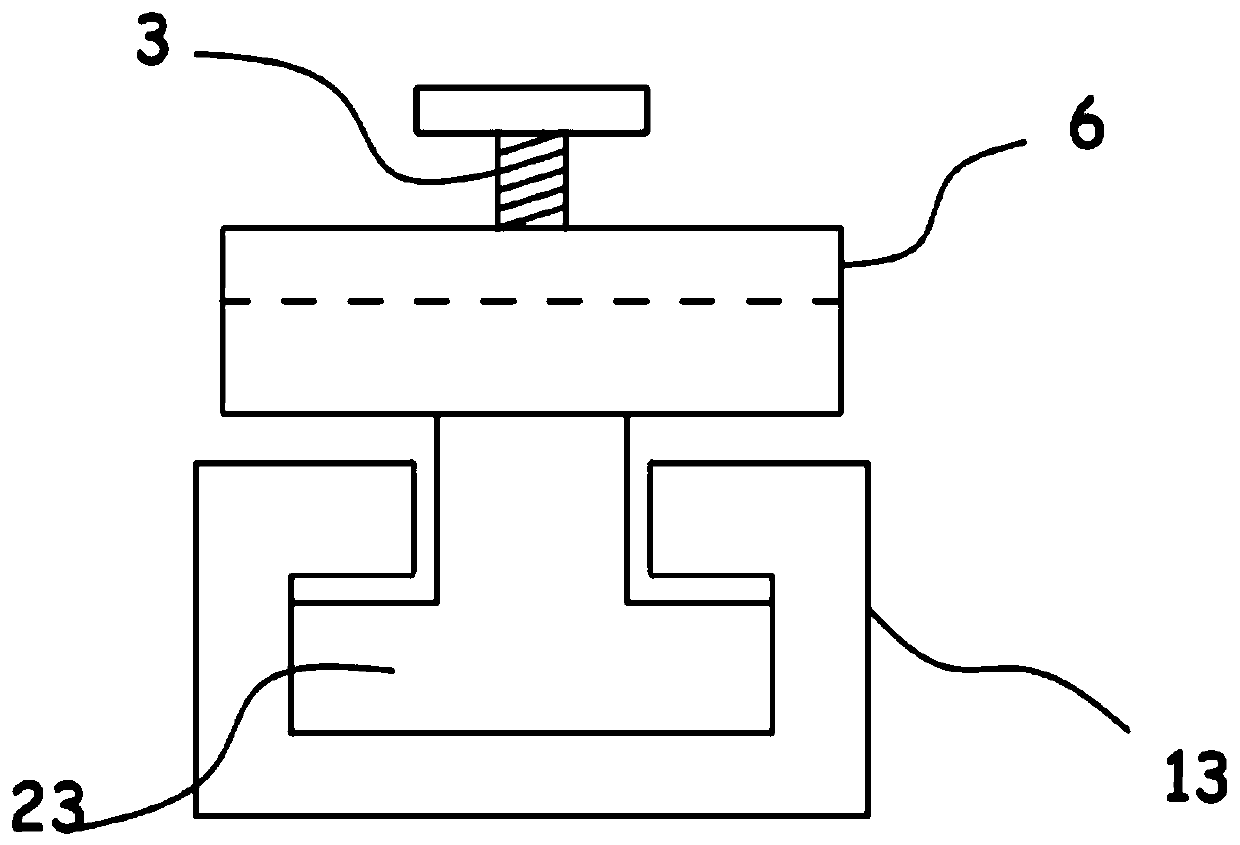

[0022] see Figure 1-4 , a device for smoothing and removing burrs on the surface of a plate, comprising a fixed frame 1, on which a guide rod 4 is fixed, and on the fixed frame 1, a support plate 13 driven up and down by a lifting mechanism is horizontally provided, and the support plate 13 is provided with a As for the clamping mechanism for fixing the plate, the fixed frame 1 is driven and connected with a sliding frame 17 which slides laterally through a reciprocating mechanism, and the sliding frame 17 is provided with a grinding mechanism for rotating and grinding the plate.

[0023] The device clamps and fixes the wooden board through the clamping mechanism provided, and realizes the grinding effect on the board through the provided grinding mechanism to remove the burrs on the surface of the board and achieve a smooth effect. 17 on the drive shaft 16, the drive shaft 16 is sleeved with a main gear 22 fixed, the bottom of the sliding frame 17 is pivotally connected with...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, a pair of fan blades 21 positioned above the grinding disc 20 are fixed on the drive shaft 16. When the drive shaft 16 rotates, the drive shaft 16 drives the fan blade 21 on it to rotate, and the fan blade 21 The airflow generated by the rotation blows down the debris and dust generated during the grinding process in time to prevent debris from accumulating on the surface of the plate and improve the quality of grinding and deburring the plate.

[0029] The lifting mechanism of the device includes a drive gear 10 driven by a drive motor 11, the drive gear 10 is meshed with a driven gear 9, and the fixed frame 1 is rotatably equipped with two coaxially fixed threaded rods with opposite helical directions. 12. The threaded sleeve on the threaded rod 12 is provided with a threaded block 8, and the support rod 7 is hinged between the threaded block 8 and the support plate 13.

[0030] Through the above arrangement, the drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com