Special aluminum casting joint for aluminum alloy vehicle body frame

A body frame, aluminum alloy technology, applied in the direction of connection, transportation and packaging between vehicle components and superstructure sub-assemblies, can solve the problems of inability to guarantee the strength of the welding position, long welding position, and difficult welding, etc. Achieve the effect of avoiding defects and reducing mechanical properties, improving production efficiency, and reducing body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

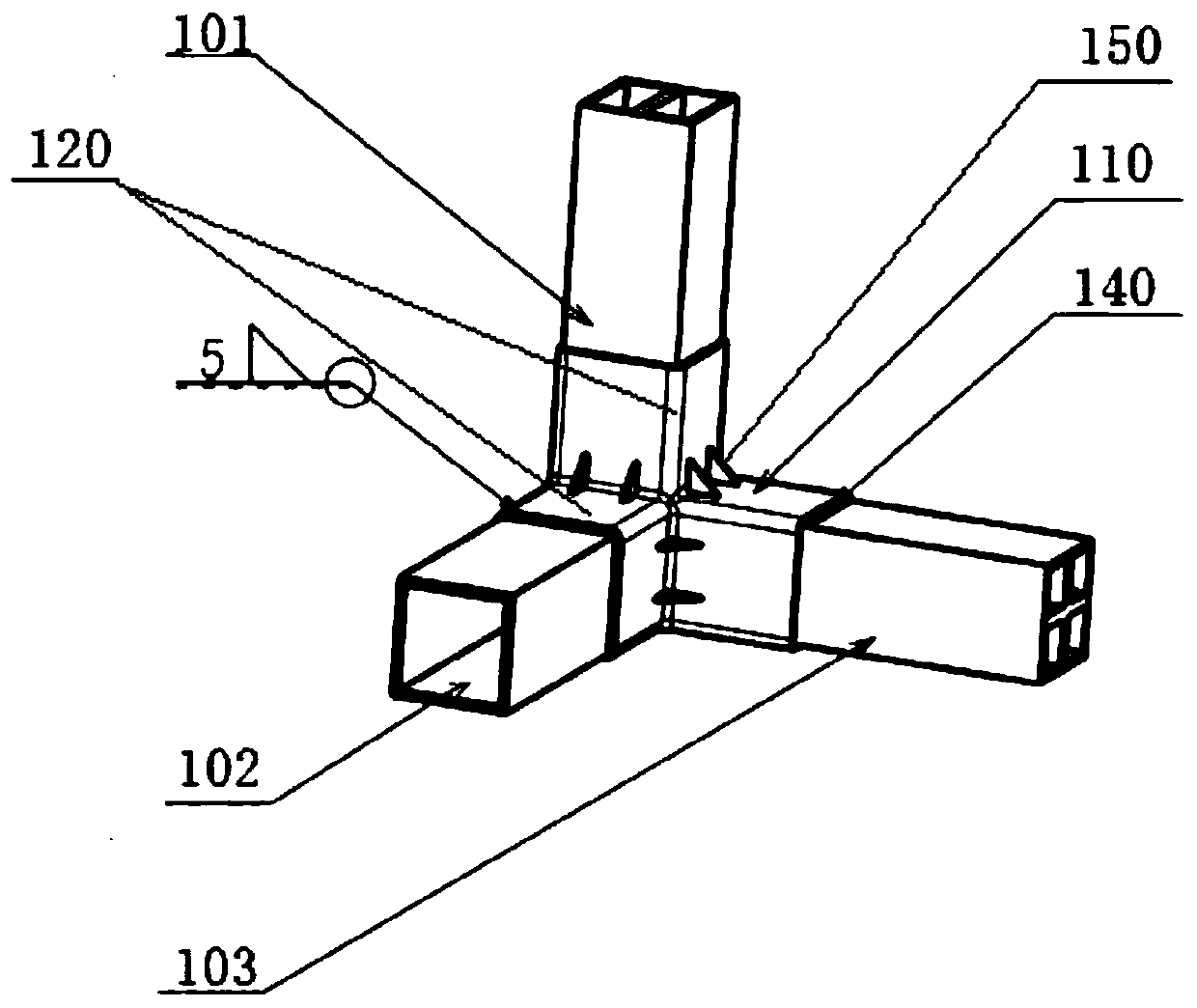

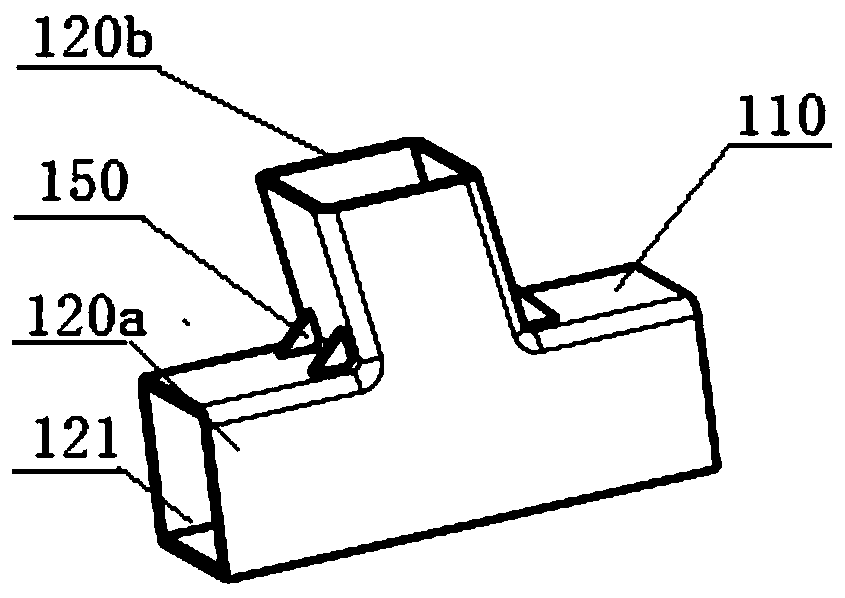

[0049] like figure 2As shown, there are two second connecting parts, wherein, one second connecting part 120a is coaxially fixedly connected with the first connecting part 110, and the other second connecting part 120b (the axis of) is connected with the first connecting part 110 (the axis ) has a first included angle α; and the value range of the first included angle α is: 0°<α<180°. A reinforcing rib 150 is connected between the first connecting portion 110 and the second connecting portion 120b, and a reinforcing rib 150 is also connected between the second connecting portion 120a and the second connecting portion 120b. Wherein, the cross-sections of the two second connecting grooves 121 and the first connecting groove 111 are both square-shaped. Each end face of the cast aluminum joint is connected with the aluminum alloy profile by MIG welding seam. The cast aluminum joint structure in Example 1 can be used to connect aluminum alloy profiles with cross-sectional outer ...

Embodiment 2

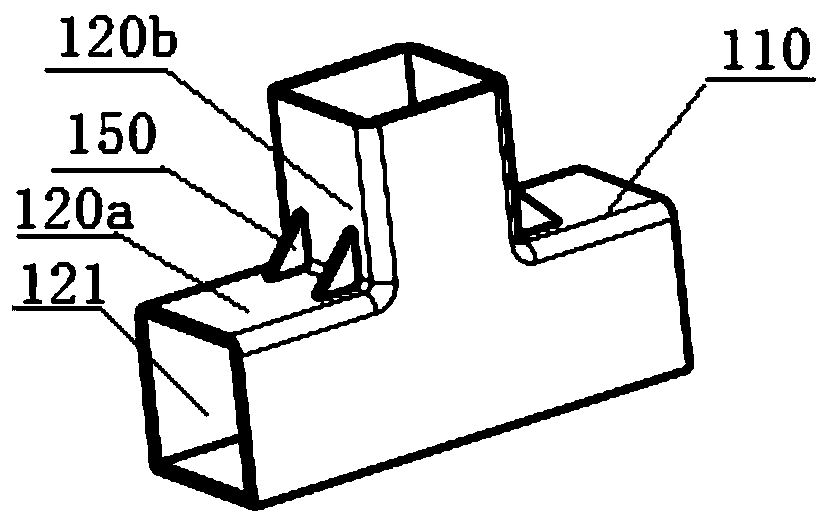

[0052] like Figure 3-4 As shown, this embodiment is a special case of Embodiment 1, and its connection mode and cross-sectional shape are the same as Embodiment 1. In Embodiment 2, the second connecting portion 120b (the axis) is connected to the first connecting portion 110 (the axis) between the first angle α=90°. Each end face of the cast aluminum joint is connected with the aluminum alloy profile by MIG welding seam.

[0053] The strength of the weld area of the aluminum alloy material is about 50%-60% of the strength of the base metal, and the area around the weld is the weak area of the overall structure. Due to the existence of the weld, the strength and stiffness of the welded aluminum alloy profile structure will be significantly reduced. The overall frame structure formed by welding the cast aluminum joints and aluminum alloy profiles in this embodiment can effectively reduce the length of the weld seam. Compared with the structure directly welded with the same...

Embodiment 3

[0055] like Figure 5 As shown, there are two second connecting parts; wherein, there is a second angle β between one second connecting part 120a (the axis) and the first connecting part 110 (the axis), and the other second connecting part 120b ( There is a third included angle θ between (the axis of) and the first connecting part 110 (the axis), and there is a fourth included angle δ between the two second connecting parts 120a (the axis) and 120b (the axis); and the The value range of the second included angle β is: 0°<β<180°, the value range of the third included angle θ is: 0°<θ<180°; the value range of the fourth included angle δ The value range is: 0°<δ<180°; and β=θ=δ. A reinforcing rib 150 is connected between the first connecting portion 110 and the second connecting portion 120a, a reinforcing rib 150 is connected between the first connecting portion 110 and the second connecting portion 120b, and the second connecting portion 120a is connected to the second connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap