Gland device

A capping and driving device technology, applied in packaging, screw caps, flanged caps, etc., can solve problems such as uneven assembly quality, and achieve the effects of fast assembly, improved efficiency, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

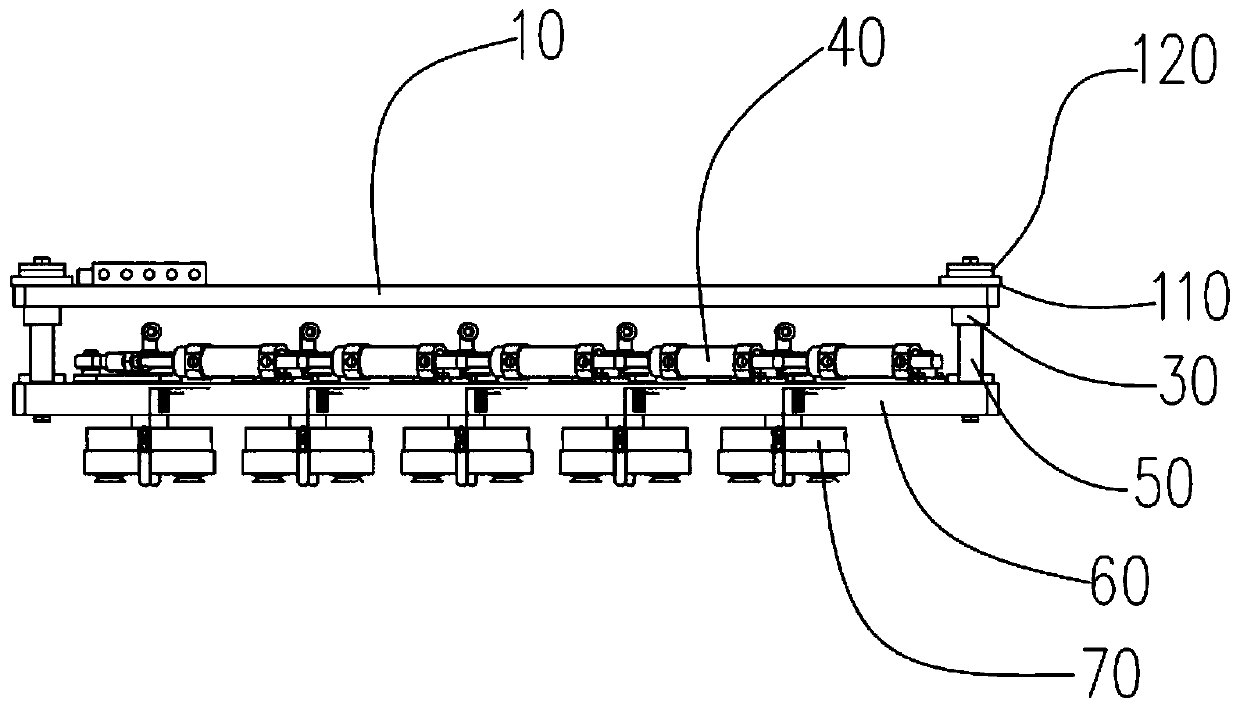

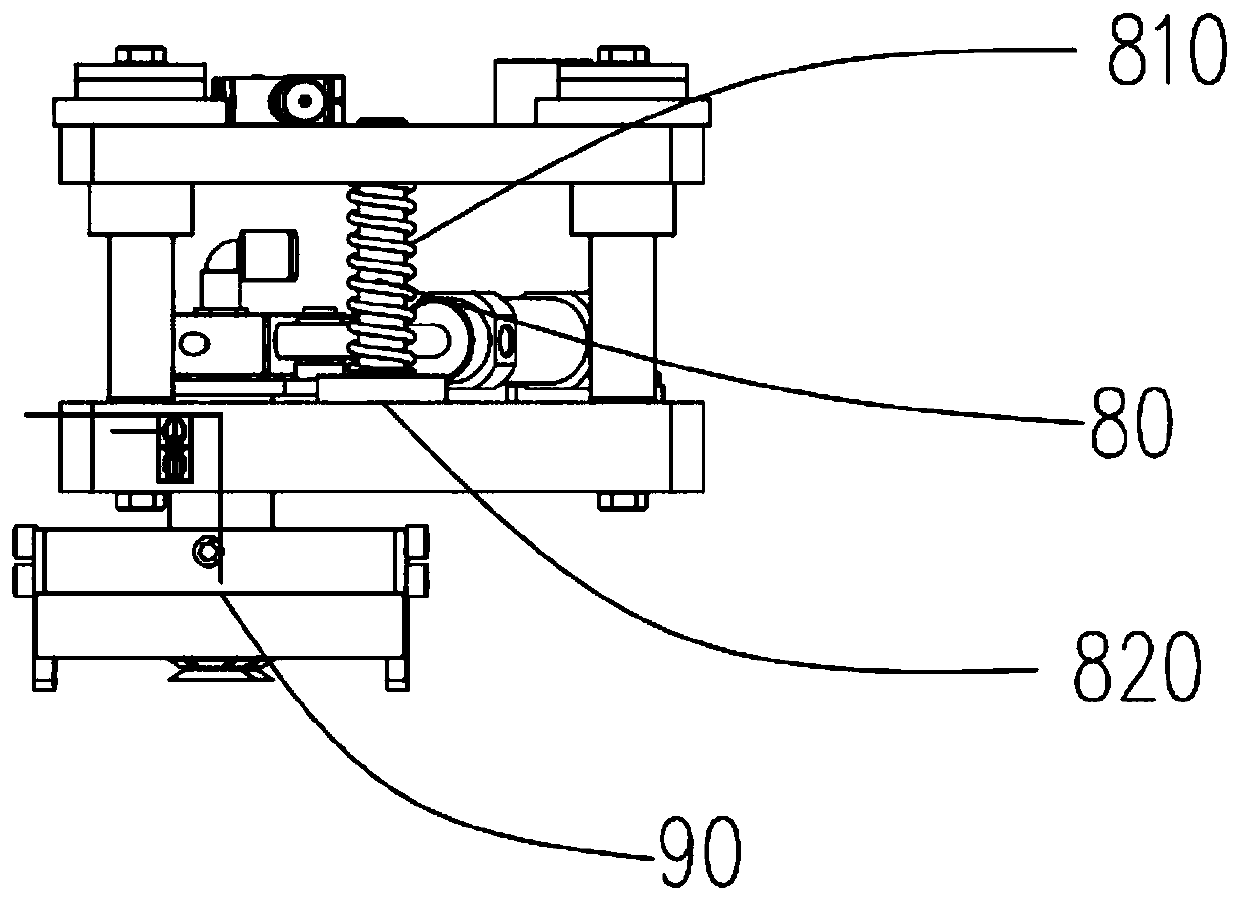

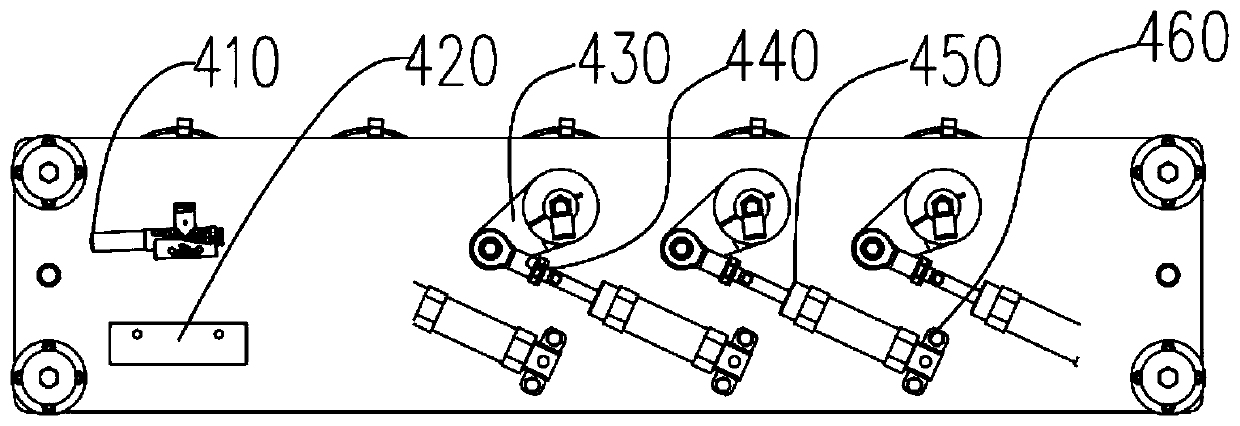

[0023] Such as Figure 1-Figure 4 As shown, the capping device in the embodiment is mainly composed of a fixing plate 10, a mounting plate 60, a capping fixture 90, a driving device 40 and other components.

[0024] Such as Figure 1-Figure 4 As shown, the mounting plate 60 is connected to one side of the fixing plate 10; the gland clamp 90 is arranged on the side of the mounting plate 60 away from the fixing plate 10, and one end penetrates the mounting plate, and the other end is provided with a clamping structure 70; the driving device 40 is disposed between the fixing plate 10 and the mounting plate 60 , and the driving device 40 is connected to the capping fixture 90 for driving the capping fixture 90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com