Two-stage a/o partial short-range series fixed bed multi-stage a/o autotrophic denitrification device and method

An autotrophic denitrification and fixed bed technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of increased treatment costs and secondary pollution of sludge, and achieves Effects of reducing difficulty, saving cost, and reducing sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

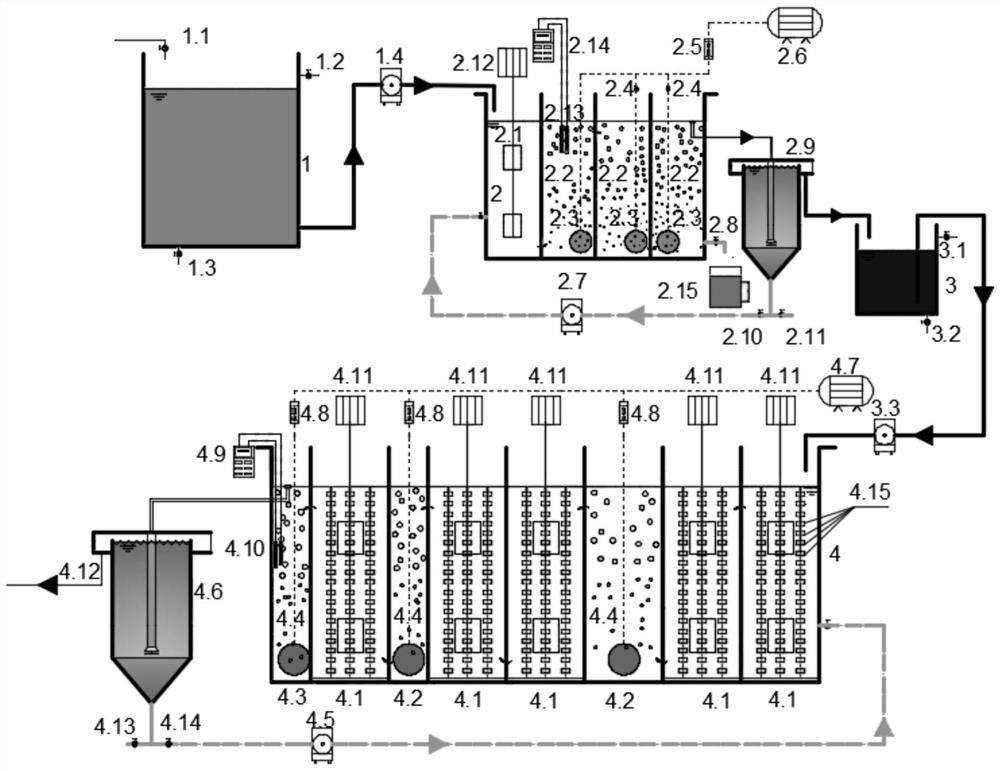

[0024] Specific implementation mode one: combine figure 1 As shown, this embodiment relates to a two-stage A / O partial short-range series fixed bed multi-stage A / O autotrophic denitrification device, which is characterized in that the main body of the process mainly includes a raw water tank (1), an A / O partial short-range reactor (2), intermediate water tank (3), fixed bed multi-stage A / O autotrophic denitrification reactor (4), secondary settling tank (4.6), characterized in that the raw water tank (1) passes through the water inlet pump (1.4) It is connected with the anoxic zone (2.1) of the A / O part short-range reactor (2); the described anoxic zone (2.1) is connected with the aerobic zone (2.2); the described anoxic zone is provided with a stirrer (2.12 ) is provided with an aeration head (2.3) in the aerobic zone (2.2), and oxygen is provided by an aeration pump (2.8); the anoxic zone (2.1) and the aerobic zone (2.2 ) volume ratio is 1:3; the sludge discharge of the A / O...

specific Embodiment approach 2

[0025] Specific implementation mode 2: This implementation mode relates to an application method of a two-stage A / O partial short-range series fixed bed multi-stage A / O autotrophic denitrification device, which is carried out according to the following steps:

[0026] 1. Inoculation sludge stage

[0027] Inoculate the reflux sludge of the secondary settling tank of the urban sewage treatment plant in the A / O part of the short-range reactor, control the sludge concentration MLSS to 2500-3500mg / L, and take the actual domestic sewage as the treatment object, and the sludge reflux ratio is 100%. The DO in the aerobic reaction zone is controlled to 1-3mg / L in the first aerobic grid according to the water flow direction, 0.8-1mg / L in the second grid, and DO in the last grid to make it less than 0.5mg / L. The hydraulic retention time is designed to be 45-60min in the anoxic zone and 135-180min in the aerobic zone. The sludge age HRT is designed to be 4-6 days, and a shorter HRT ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com