Molten glass guiding device, molten glass guiding channel and molten glass quality improvement method

A diversion device and diversion channel technology, applied in glass furnace equipment, glass manufacturing equipment, feeding troughs, etc., can solve problems such as inhomogeneity and glass liquid surface impurities, reduce flow resistance, shorten flow path, The effect of improving the quality of glass products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

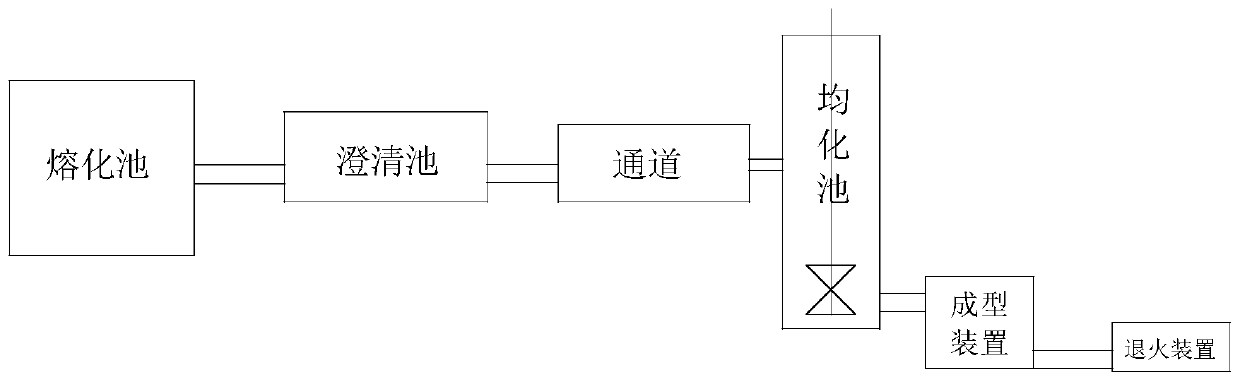

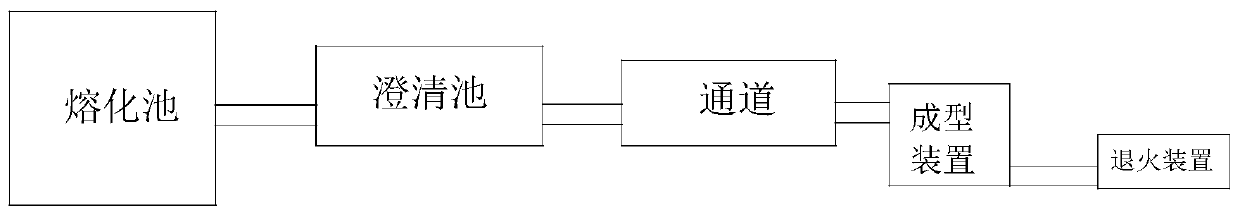

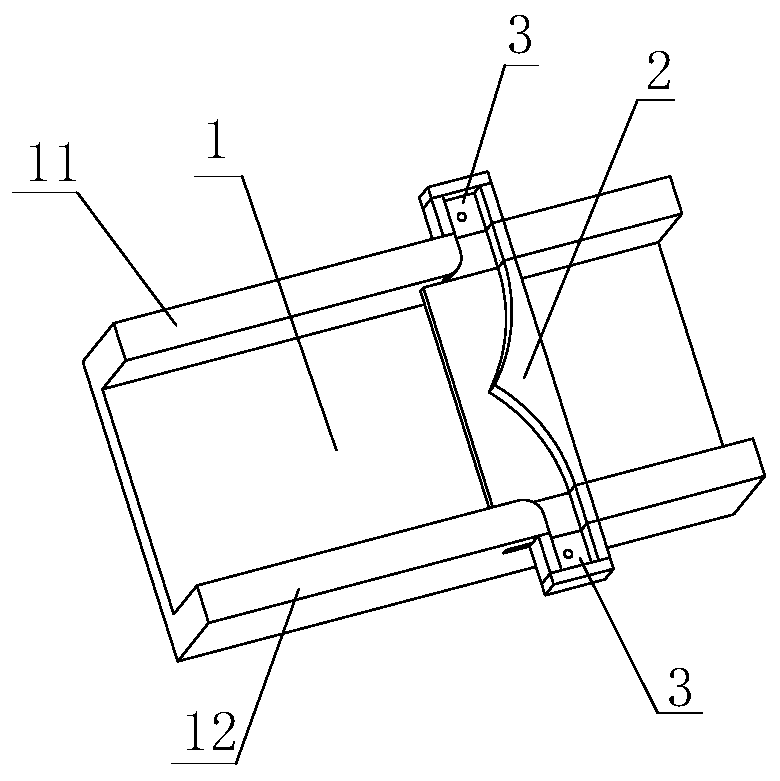

[0040] The glass production process is mainly divided into two parts, thermal process and cold process. Among them, the thermal process is mainly to convert the glass powder into a liquid state at high temperature, and form glass products through melting, clarification, homogenization, molding, and annealing. The key equipment corresponding to the above processes generally includes melting pools, clarification pools, channels, Homogenizing tank, molding device and annealing device, etc., such as figure 1 and 2 shown. In the figure, the schematic diagrams of the process positions of the two molten glass channels are given to match the process settings. As the transition area of each important production link, the channels can appear in different positions according to the design requirements, and can also serve as clarification tanks, homogenization tanks, etc. Part of the function of the equipment can also be used to control the temperature change of the glass liquid. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com