Detergent feeding device and feeding method and washing machine

A technology of detergent feeding and feeding device, applied in the field of washing machines, can solve problems such as the complex structure of the material box, and achieve the effects of ensuring effectiveness, simple structure and improving feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

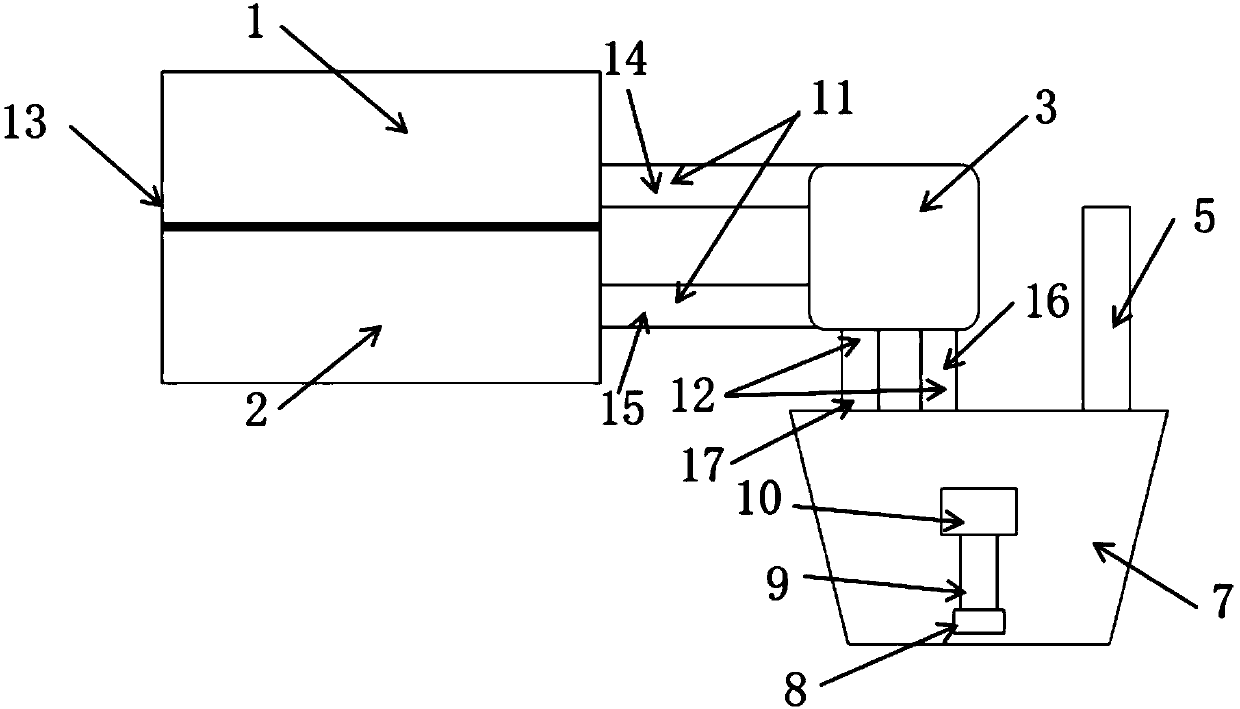

[0035] A detergent dispensing device, such as figure 1 , the feeding device includes a detergent box 13, a feeding pump 3 and a feeding device 7; the feeding pump 3 includes a liquid inlet pipe 11 and a liquid outlet pipe 12, and the liquid inlet pipe 11 is connected with the detergent box 13, so The liquid outlet pipe 12 is connected with the dispenser 7 , and the dosing pump 3 extracts the detergent in the detergent box 13 and puts it into the dispenser 7 . Described feeding device is provided with water inlet branch 5, and described dispenser 7 is connected with water inlet branch 5; Detergent mix. The dispenser 7 body is provided with a siphon pipe 9 with a siphon hole; the siphon pipe 9 is a hollow pipe, and its bottom forms an inlet 8 on the dispenser 7, and the inlet 8 communicates with the washing machine inner barrel. The end of the siphon tube 9 away from the bottom surface of the dispenser 7 is covered with a siphon cap 10; the siphon tube 9 cooperates with the si...

Embodiment 2

[0052] The principle of this embodiment is the same as that of Embodiment 1, and its main difference is:

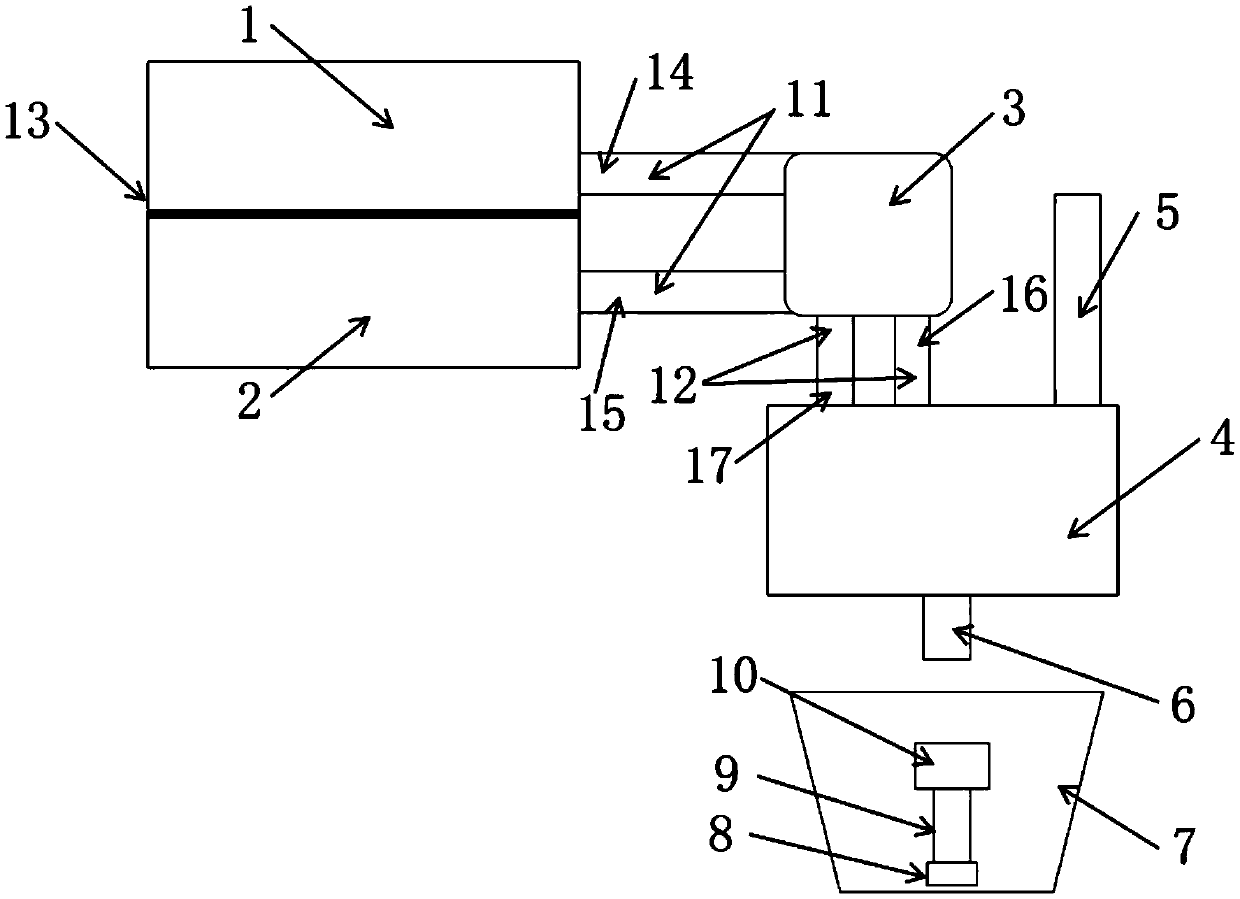

[0053] Such as image 3 , the delivery device includes a dispenser box 4; the liquid inlet pipe 11 of the delivery pump 3 is connected with the detergent box 13, the liquid outlet pipe 12 of the delivery pump 3 is connected with the distributor box 4, and the delivery The pump 3 pumps out the detergent in the detergent box 13 and puts it into the dispenser box 4 . The feeding device is provided with a water inlet branch 5, and the water inlet branch 5 is arranged on the distributor box 4; the distributor box 4 is provided with a nozzle 6, and the nozzle 6 is connected with the dispenser 7 The water inlet branch 5 throws water into the dispenser box 4, and mixes with the detergent in the dispenser box 4, and the water flow carries the detergent into the dispenser 7 through the nozzle 6.

[0054] Preferably, the detergent box 13 includes a first liquid storage chamber 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com