Fabricated construction method of railway deck components

A construction method and technology of railway bridges, applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as difficulties in construction management, large fluctuations in prefabricated quality, and reduced construction speed, so as to achieve simple and easy installation of equipment and tooling operation, reduce labor and labor input, and reduce the effect of component damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

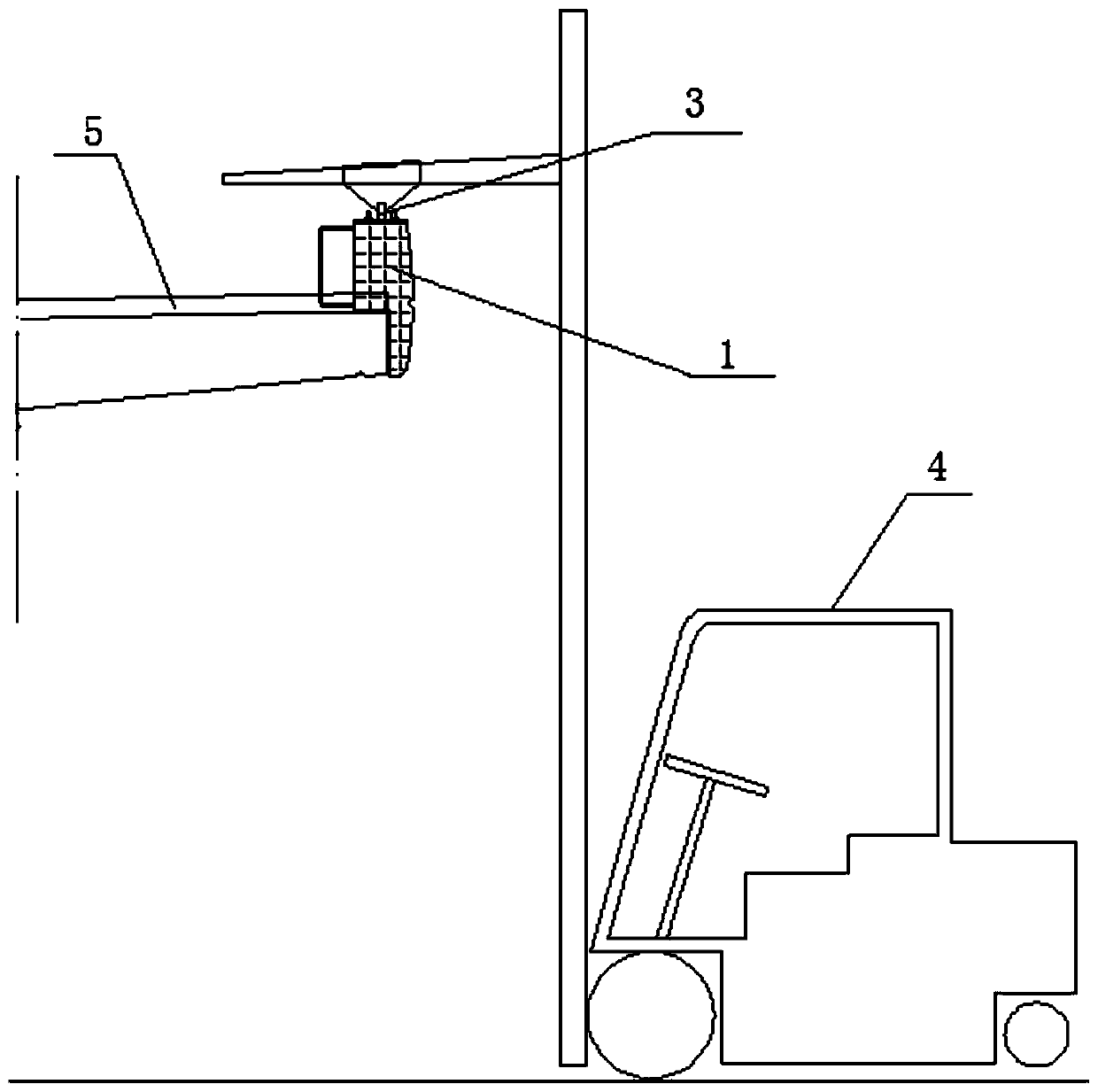

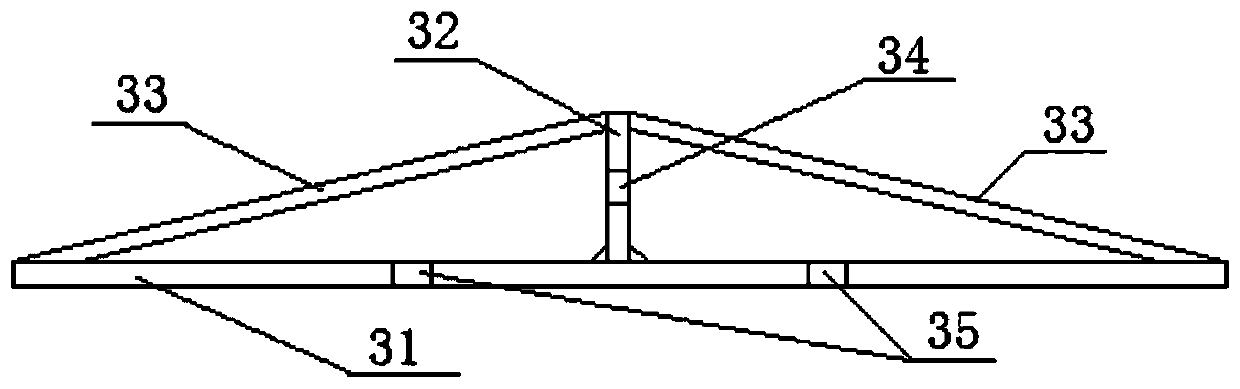

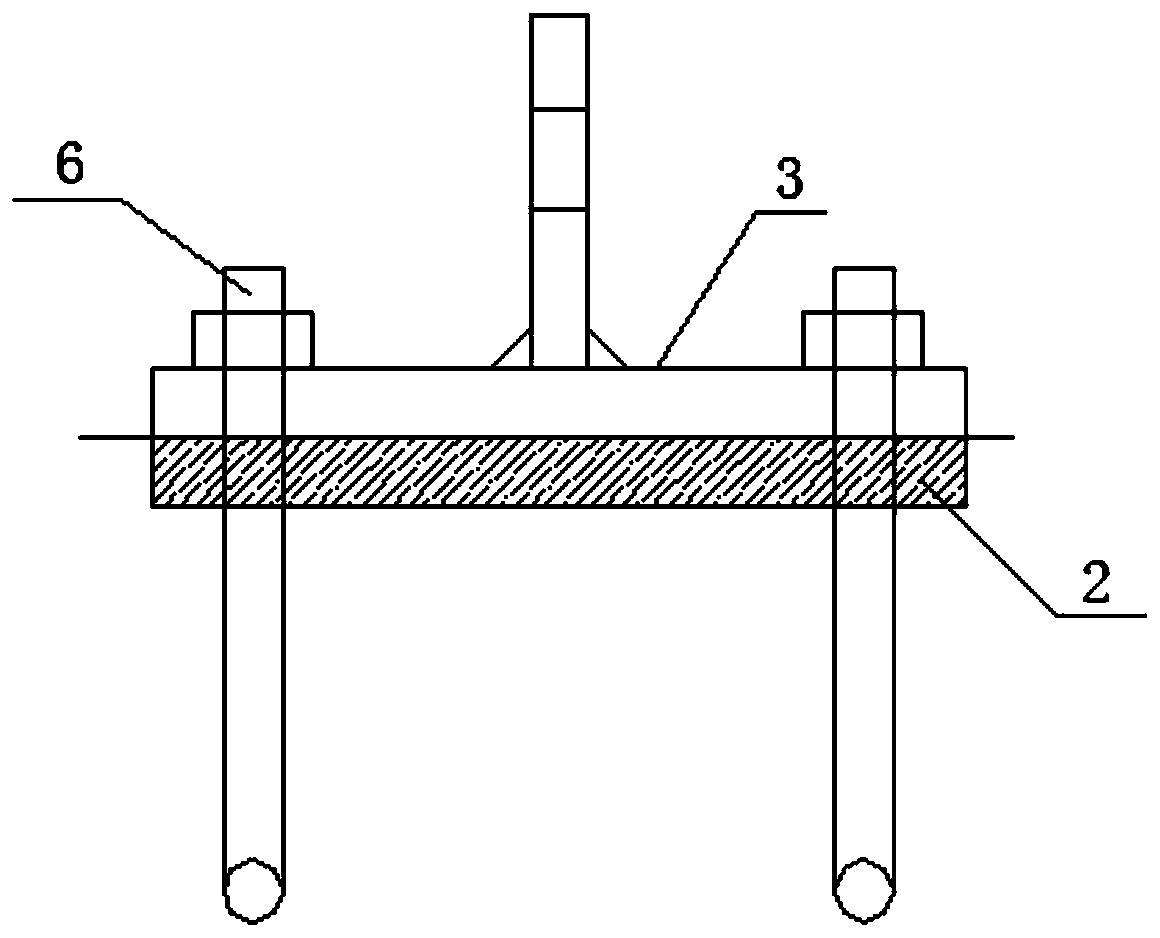

[0023] See Figure 1-Figure 4 , an assembly type construction method of railway bridge deck components, specifically includes the following steps:

[0024] (1) Prefabrication process: The bridge deck prefabricated components are automatically processed, prefabricated, produced, and stored in the prefabrication yard, and different types of bridge deck prefabricated components are prefabricated and stored in different areas; among them, the prefabrication yard p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap