Synchronous pouring construction method of small rock-fill concrete reservoir

A technology of rockfill concrete and simultaneous pouring, which is used in construction, dams, barrages, etc., can solve the problem of poor fit between the waterproof structure and the main part of the dam body, the tightness of the anti-seepage layer and the main body of the dam body, and the quality of concrete pouring. Unable to guarantee and other problems, to achieve the effect of good bonding tightness, improved anti-seepage performance, and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the accompanying drawings.

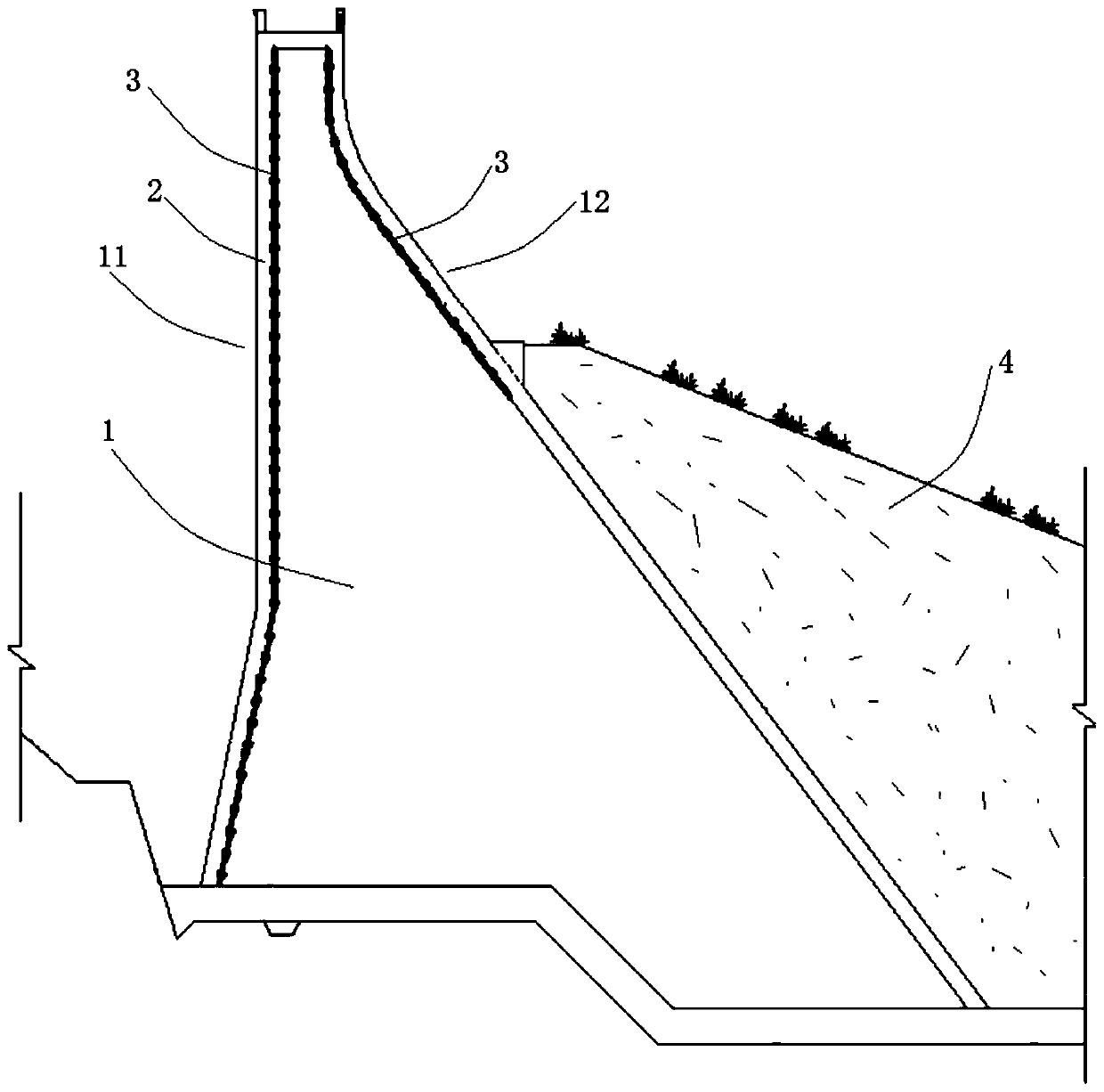

[0039] Referring to the accompanying drawings, it is a synchronous pouring construction method for a rockfill concrete pond dam disclosed in the present invention, comprising the following construction steps:

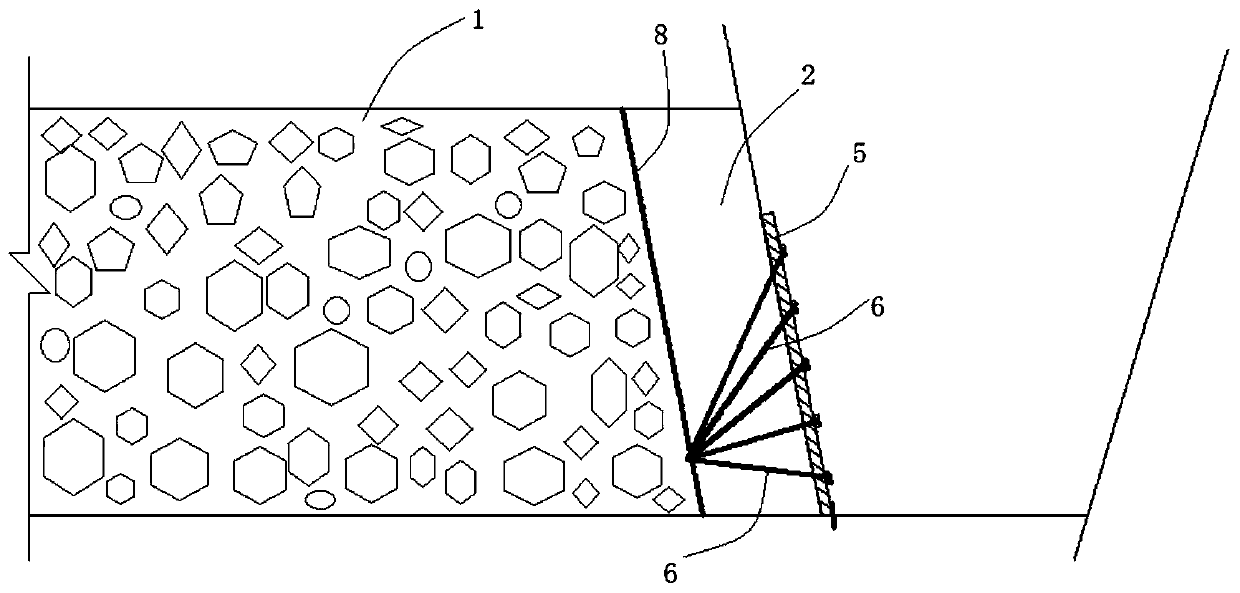

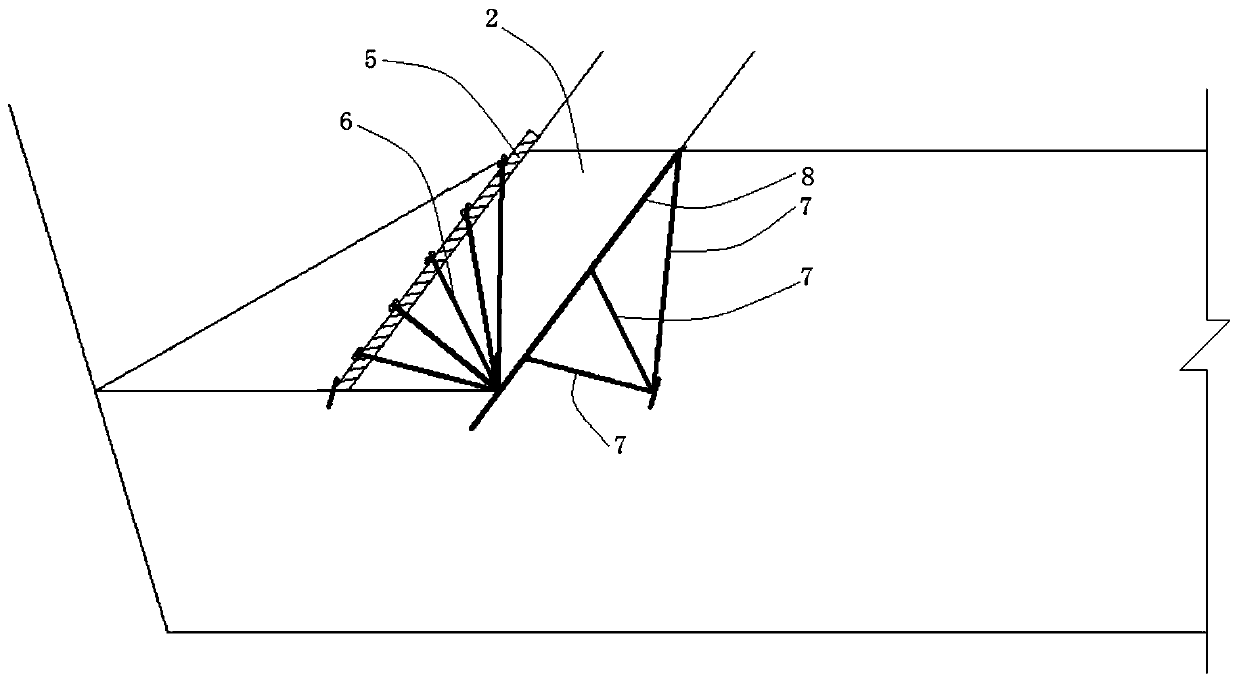

[0040]S1: The erecting steel bars are applied, and the erecting bars are horizontally spaced along the upstream surface 11 of the dam body 1 to form the reinforcing bar mesh surface 8 of the upstream surface 11, and the steel bars are in a natural support state; The steel bars form the steel mesh surface 8 of the downstream face 12, and the anchor rods 7 are set at intervals of 1m on the large-angle slope of the downstream face 12, and the distance between the anchor rods 7 and the impermeable layer 2 is 1m, and three steel bars are used for support Fix the steel mesh surface 8 of the downstream surface 12, and the diameter of the steel bar is 20mm;

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap