Sound absorption wall and mounting method thereof

A technology of wall and sound-absorbing cotton, which is applied in the direction of covering/lining, building, building structure, etc. It can solve the problems of unsatisfactory sound-absorbing effect of partition walls, poor sound-insulating effect, and low construction efficiency, so as to reduce decoration costs and improve sound-absorbing effect, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

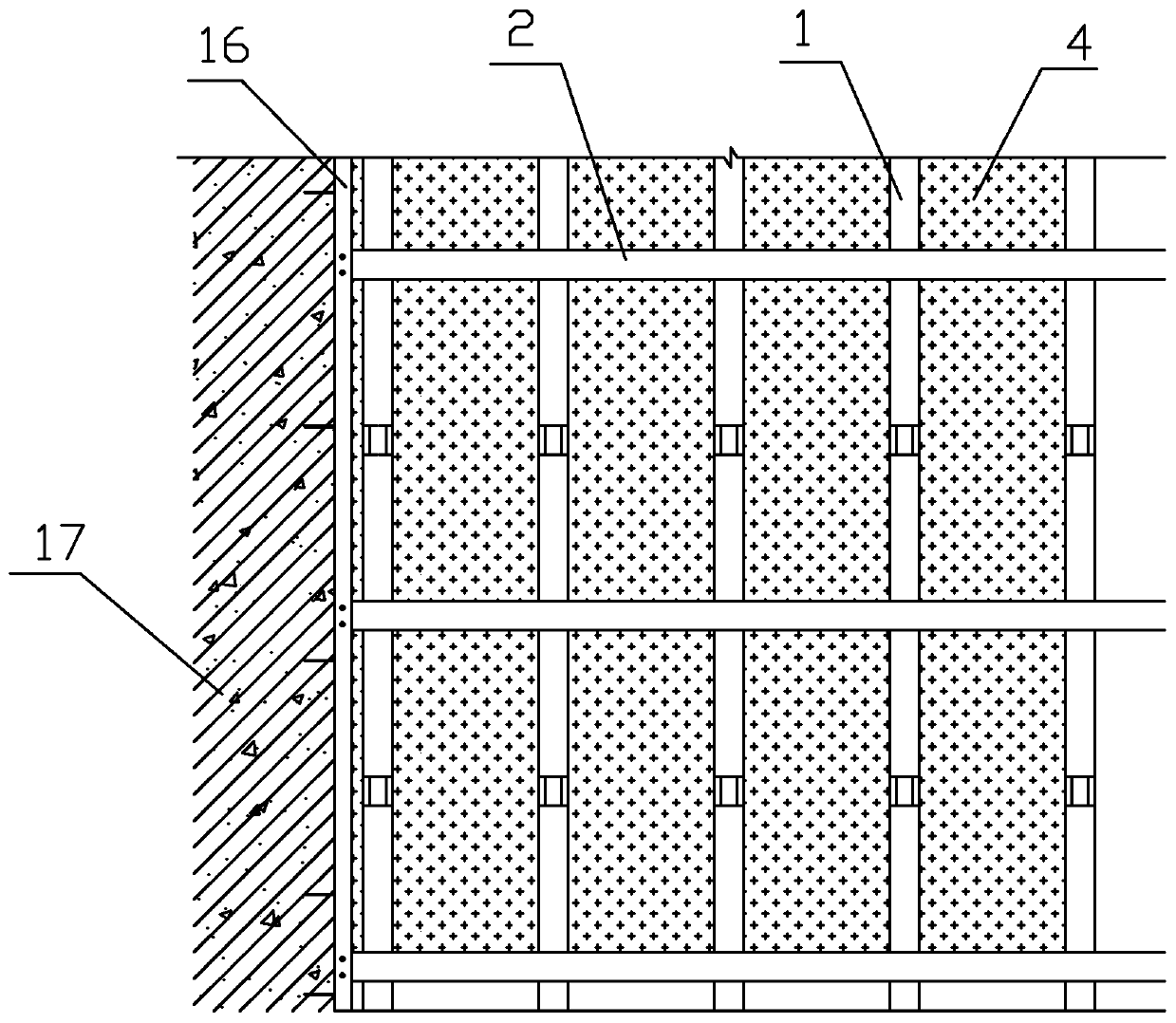

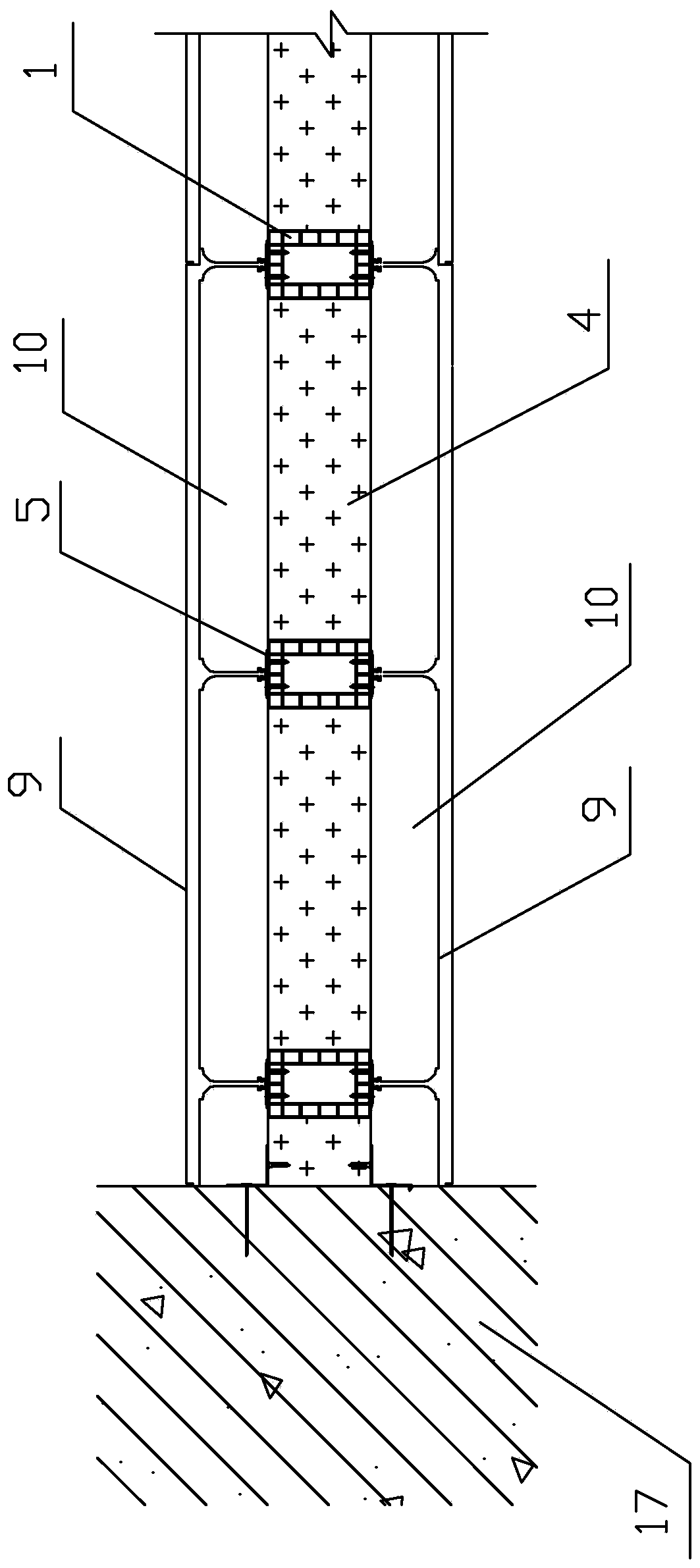

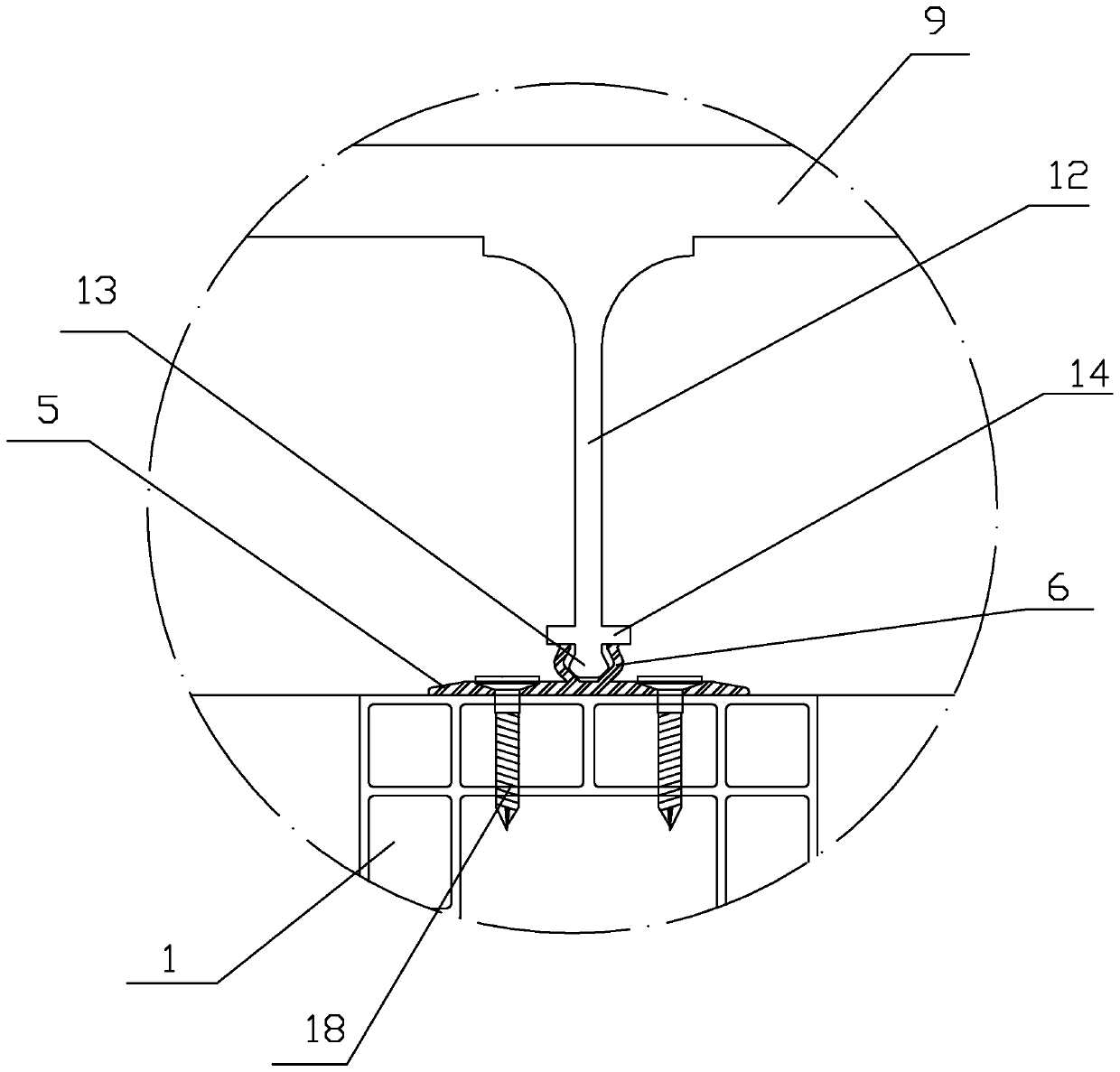

[0029] Embodiment: a kind of sound-absorbing wall body of this embodiment, such as figure 1 , figure 2 As shown, including the interior wall and the exterior wall enclosing the interior wall. The inner wall includes a grid skeleton and sound-absorbing cotton. The grid skeleton is formed by cross-connecting multiple vertical keels 1 and multiple horizontal keels 2, such as Figure 4 As shown, the vertical keel is a long profile, and there are a plurality of notches 3 evenly distributed along the length direction of the vertical keel on the vertical keel. The cross section of the vertical keel is hollow and rectangular. The horizontal keel is stuck in the notch of the vertical keel, the vertical keel and the horizontal keel are located on the same plane, the vertical keel and the horizontal keel interlock to form a grid skeleton, the sound-absorbing cotton 4 is a conventional building material, and the sound-absorbing cotton is placed in each grid of the grid skeleton form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com