A five-point gripping decorative brick and its mounting method

A decorative brick and mounting technology, which is applied in the direction of covering/lining, construction, building structure, etc., can solve the problems of difficulty in ensuring the overall quality of the decorative brick, hollowing of the decorative brick and the wall, and potential safety hazards, so as to reduce the risk of falling off Risk, strong fit, and safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

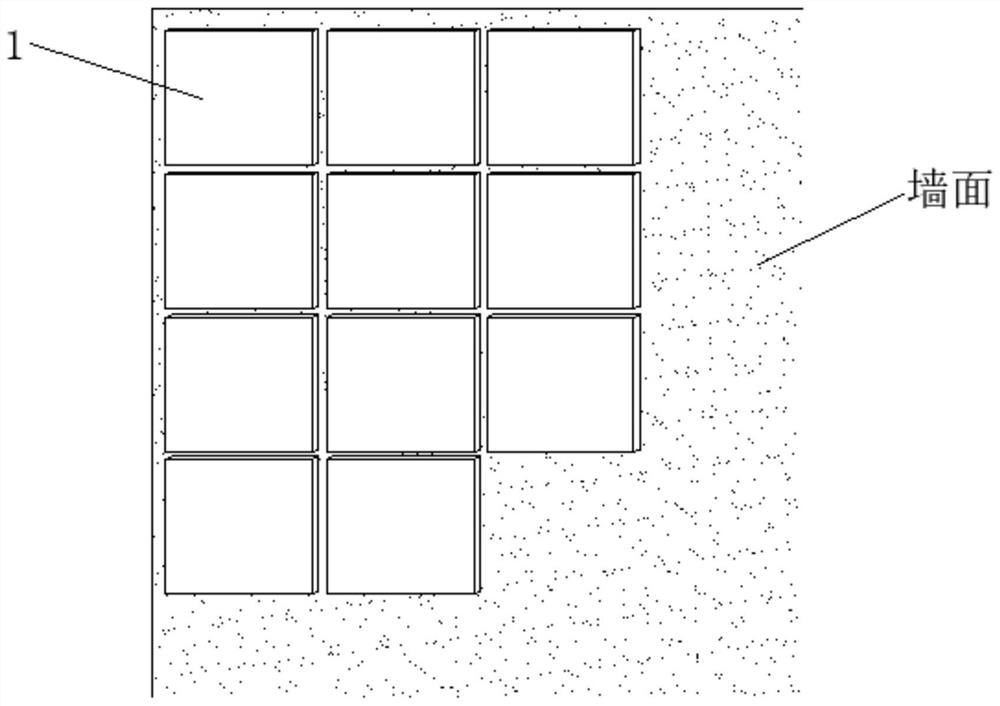

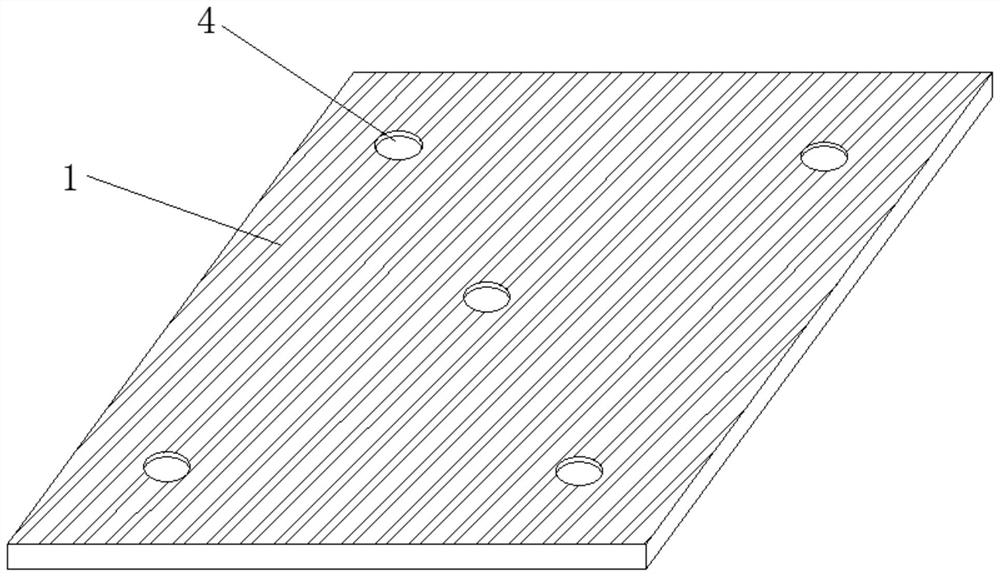

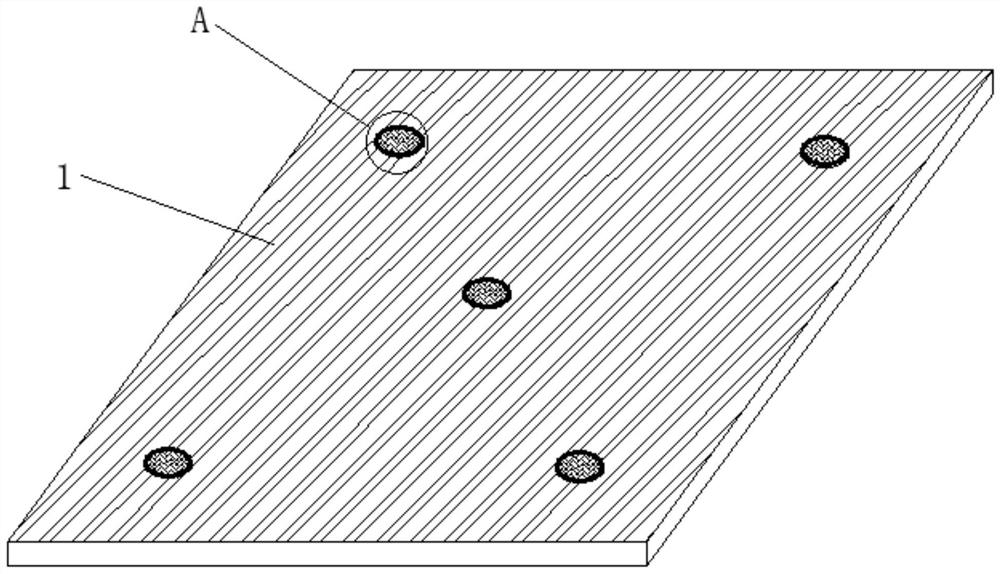

[0049] see figure 1 and figure 2 , a five-point gripping decorative brick, including a decorative brick body 1, a plurality of T-shaped reserved grooves 4 are excavated on the back of the decorative brick body 1, and the plurality of T-shaped reserved grooves 4 are evenly arranged on the decorative brick body 1 on; see image 3 and Figure 4 , the inner end of the T-shaped reserved groove 4 is connected with a T-shaped deformed grasping body 3, please refer to Figure 11 The side ends of the T-shaped deformed grasping body 3 are fixedly connected with a plurality of special-shaped auxiliary grasping feet 33, and the plurality of special-shaped auxiliary grasping feet 33 are evenly distributed on the T-shaped deformed grasping body 3 from top to bottom, and the T-shaped deformed A cavity 34 is dug into the inner end of the grasping body 3, and a solidified adhesive ball 36 is arranged in the cavity 34, and a composite cured adhesive is wrapped in the cured cemented ball 36,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com