Detachable locating and mounting rack for ceiling board

A technology for positioning installation and ceiling suspension, which is applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of inconvenient disassembly, low installation efficiency, and difficult installation, and achieves reduction of installation difficulty, improvement of installation efficiency, and reduction of labor. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

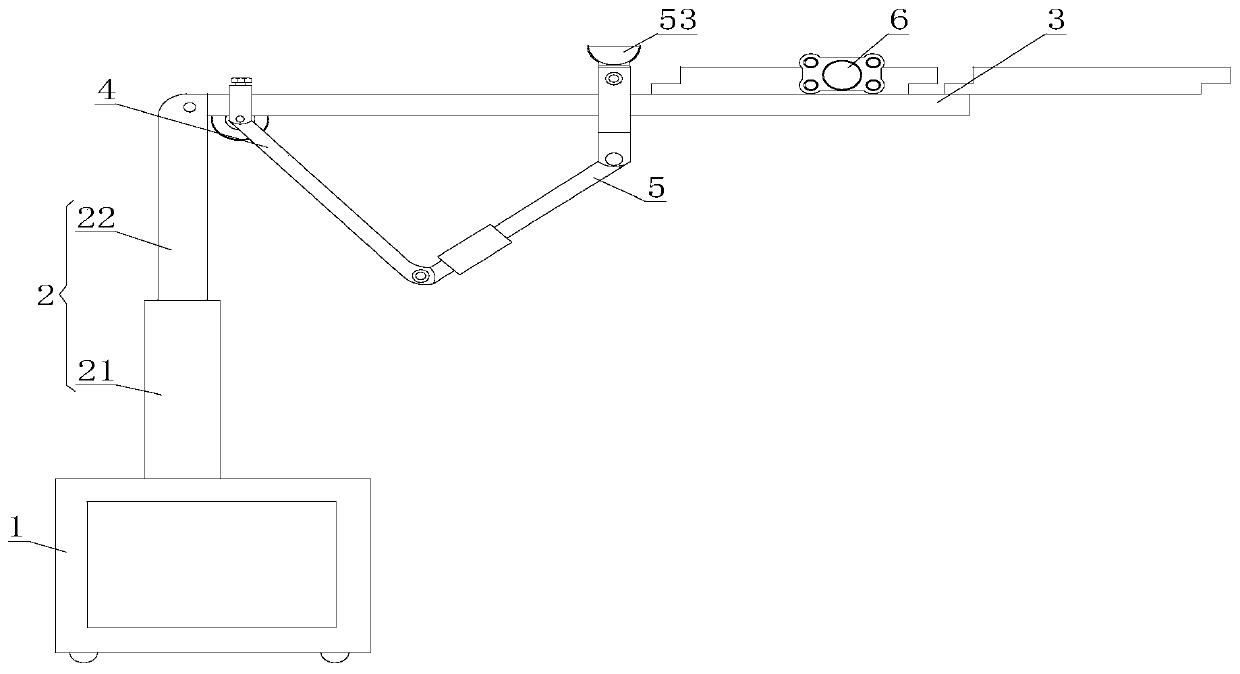

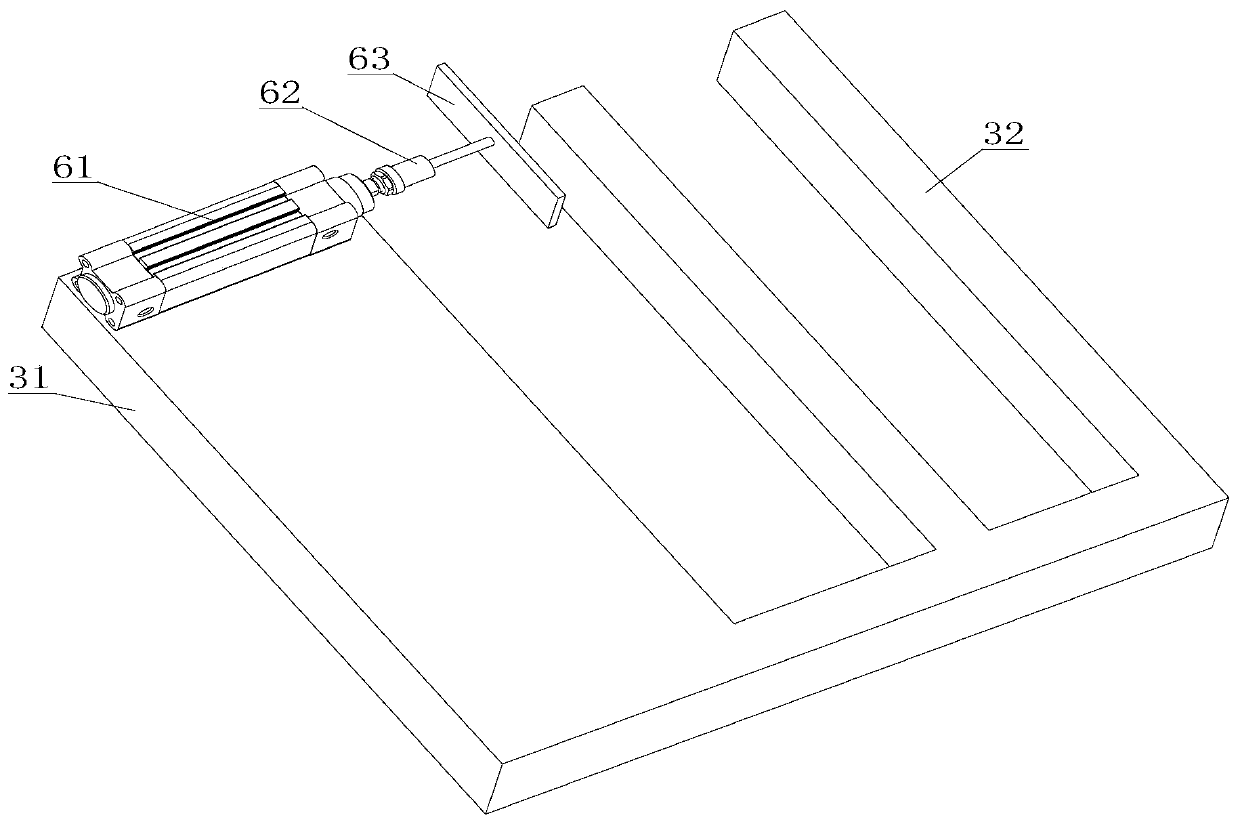

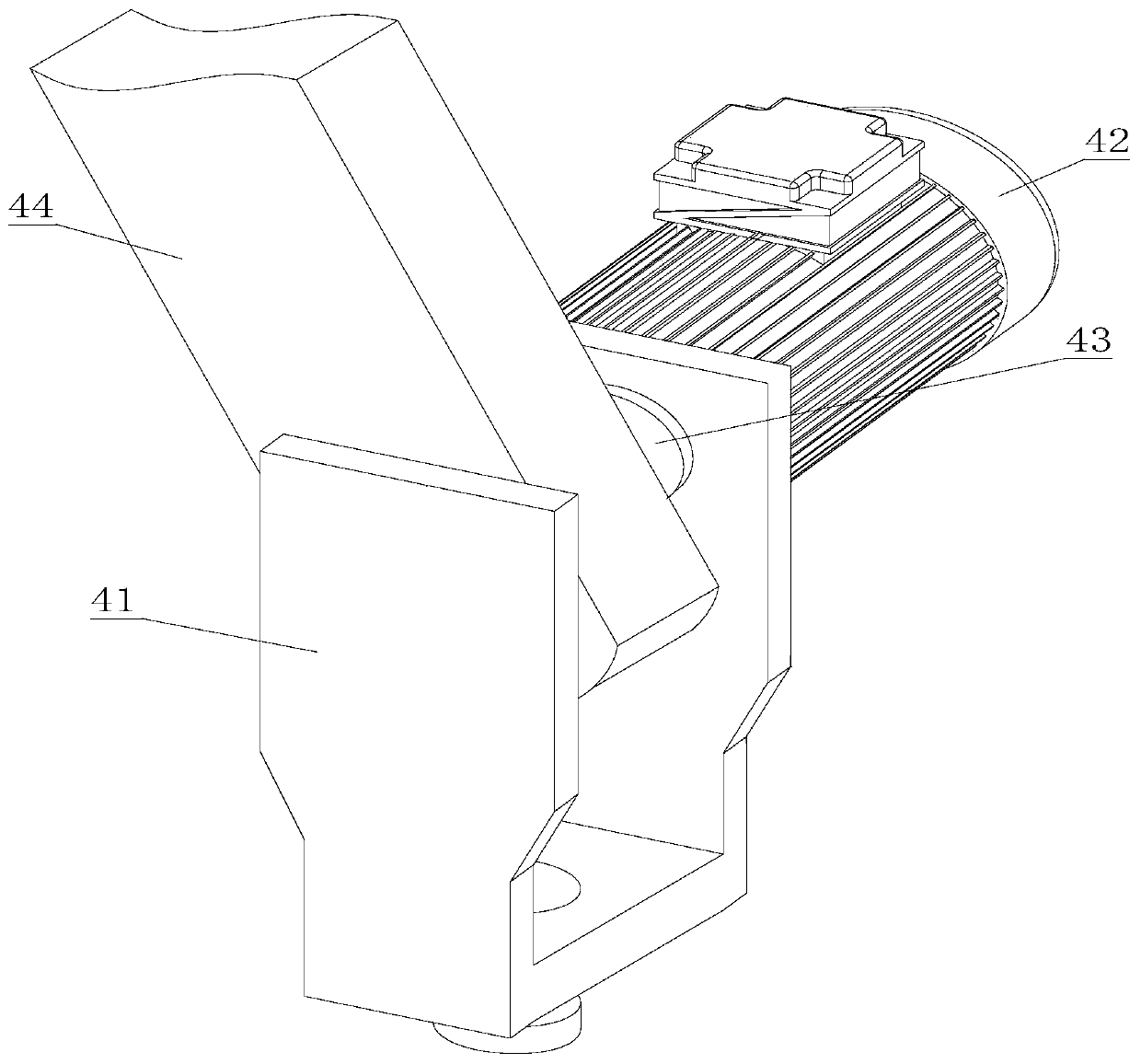

[0027] see figure 1 , a detachable positioning installation frame for ceiling panels, including a base 1, a lifting rod 2, an end plate 3, a first rocker arm 4, a second rocker arm 5 and a pushing mechanism 6, and the upper surface of the base 1 is fixedly connected with a lifting rod 2. The lifting rod 2 includes a cylinder base 21 and a cylinder rod 22. The cylinder base 21 is movably connected to the cylinder rod 22. The lower end of the cylinder base 21 is connected to the base 1 through bolt locking, and the upper end of the cylinder rod 22 is connected to the cylinder through bolt locking. The rod 22, the cylinder seat 21 in the lifting rod 2 drives the cylinder rod 22 to rise, and drives the end plate 3 to rise as a whole, until the upper surface of the end plate 3 abuts against the lower surface of the installed ceiling plate, and the upper end of the lifting rod 2 is fixedly connected There is an end plate 3, and a push mechanism 6 is installed on the upper surface of...

Embodiment 2

[0032] see Figure 8 The difference between the second embodiment and the first embodiment is that the cross section of the tooth plate 32 is circular, and the ring sleeve 52 includes a third plate body 526, a shaft hole 527 and a ball 528. The shaft hole 527 is movably connected with a ball 528 inside the shaft hole 527, and the ball 528 is rollingly connected with the gear plate 32 to reduce friction.

[0033] Working principle: Place the ceiling plate on the right end tooth plate 32 of the end plate 3, the cylinder seat 21 in the lifting rod 2 drives the cylinder rod 22 to rise, and drives the end plate 3 to rise as a whole until the upper surface of the end plate 3 abuts on the already The lower surface of the installed ceiling plate realizes the vertical movement of the end plate 3 in the direction of the Z axis; the rotation of the motor 42 drives the rotation of the rotation shaft 43, and the rotation of the rotation shaft 43 drives the rotation of the first rocker 44, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com