Automatic adjusting system of supporting intensity of advance hydraulic support group and use method thereof

A hydraulic support and support strength technology, which is applied in the directions of pillars/supports, earth-moving drilling, mining equipment, etc., can solve the problems of endangering life and property safety, affecting the implementation of mining work, uneven force, etc., to enhance work stability. and service life, improve production standards and safety, and reduce the effect of accident rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

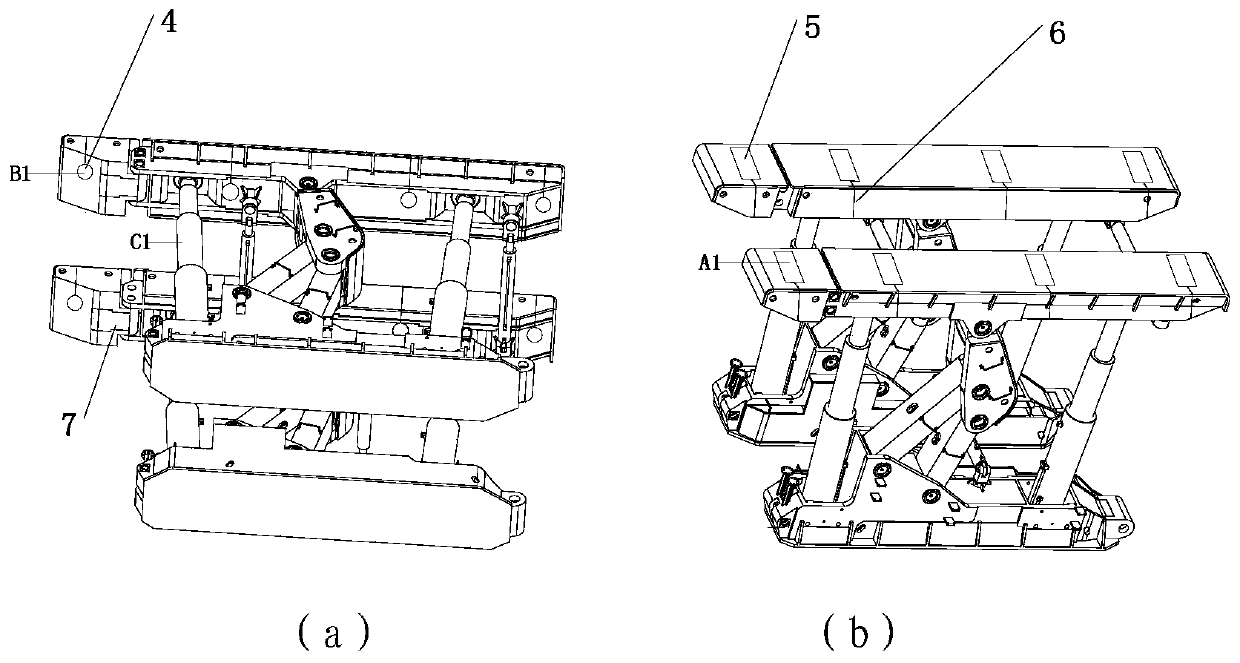

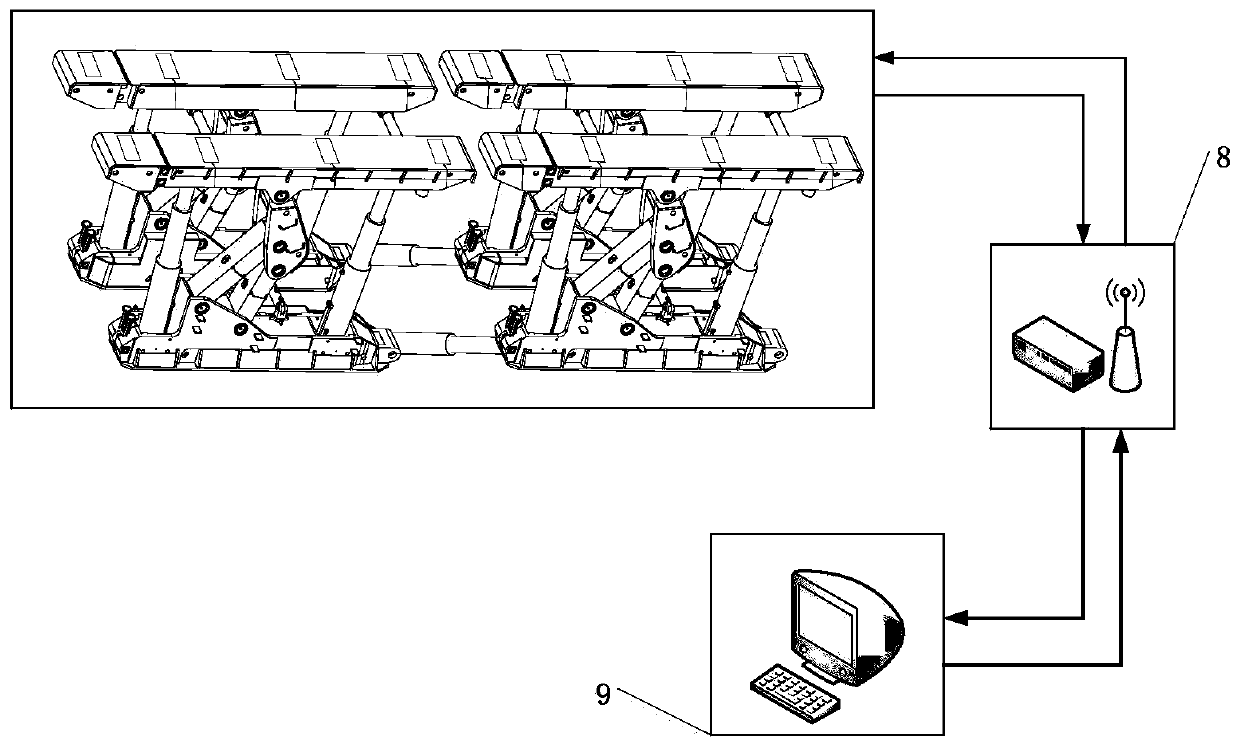

[0031] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

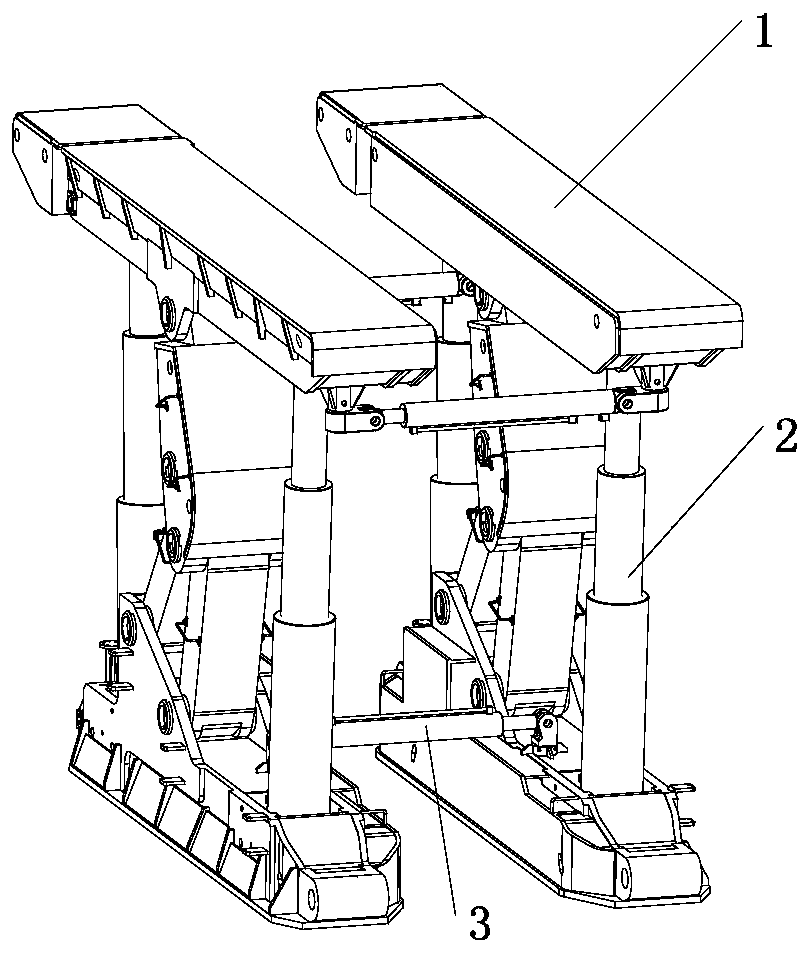

[0032] like Figure 1~3 Shown, below in conjunction with embodiment the present invention is described in further detail:

[0033] In order to solve the problem of difficult advanced support in coal mines, the present invention provides an automatic adjustment system for group support strength of advanced hydraulic supports and its use method. The whole system can be divided into: signal acquisition module, signal transmission module, signal The analysis and processing module and the signal exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com