Double-station air tightness detecting device and method applied to top cover of lithium power battery

A technology of air tightness detection and lithium battery, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of incapable of mass production, long measurement time, and affecting safety. , to achieve highly automated air tightness testing, reduce manual workload, and achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

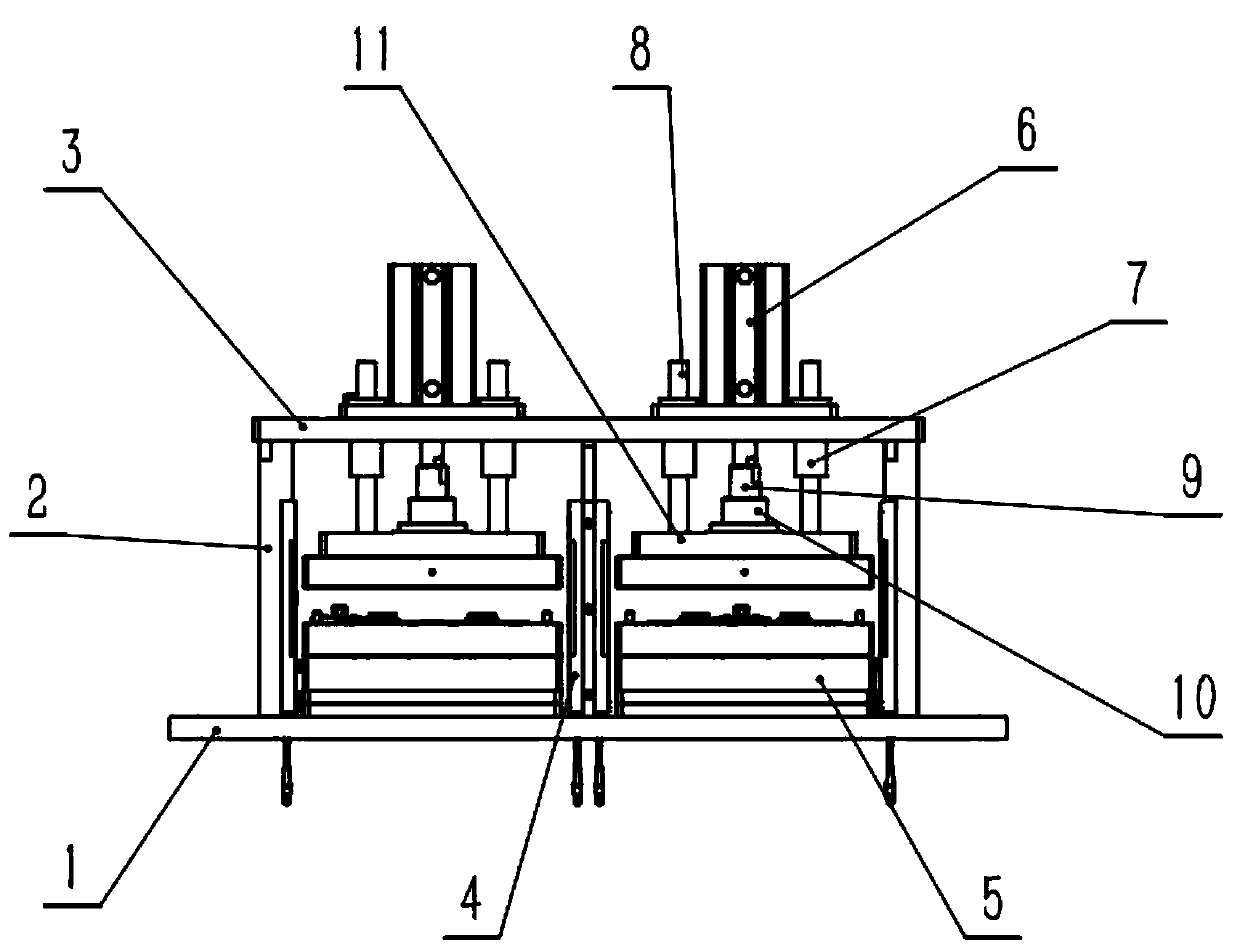

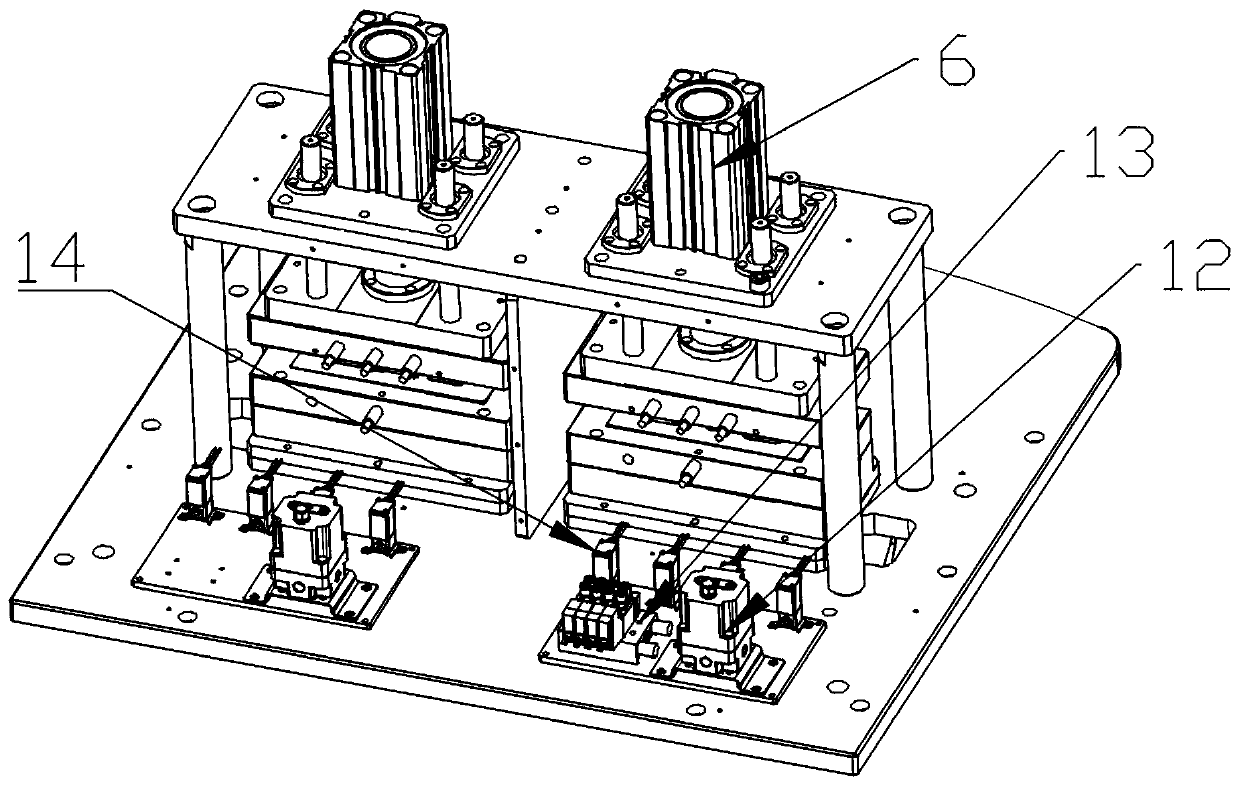

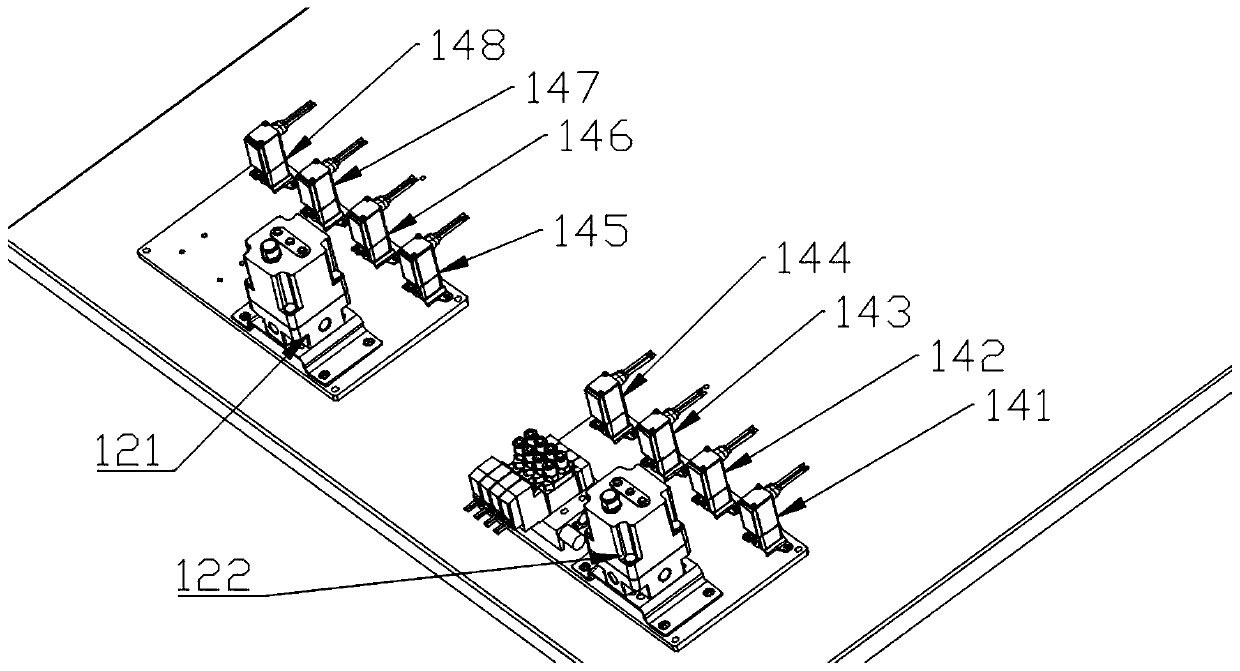

[0035] Example 1, such as Figure 1 to Figure 7 As shown, a double-station air tightness detection device applied to the top cover of a power lithium battery is provided with a driving part 100, a connecting assembly 101, a transmission part 102, a control part 103 and a sealing part 104; the driving part 100 is provided with a cylinder 6 ;

[0036] The connection assembly 101 is provided with a device bottom plate 1, a support column 2, a lower pressure mounting plate 3, a lower cavity base 5, a floating joint 9, a fixed block 10, an upper cavity base 11, and a limit block 18;

[0037] The transmission part 102 is provided with a linear bearing 7, a guide post 8, a positioning pin 17, a spring 19, and a positioning post 20;

[0038] The control part 103 is provided with a safety grating 4, a proportional valve group 12, a two-position five-way solenoid valve group 13, and a direct-acting two-way solenoid valve group 14; the sealing part 104 is provided with a lower cavity 15...

Embodiment 2

[0054] Example 2, see Figure 8-9 , this embodiment is basically the same as Embodiment 1, the difference is that the upper end of the positioning pin 17 of the lower cavity 15,

[0055] The upper cavity 16 is provided with an embedding groove 161 matched with the positioning pin 17, and an electromagnet 162 is arranged in the embedding groove 161. When the positioning pin 17 is embedded in the upper cavity 16, the electromagnet 162 is opened, and the positioning pin and the positioning pin are connected to each other. The fixedly connected lower cavity 15 is attracted upwards, so that the gap between the upper cavity 16 and the lower cavity 15 is closed, the sealing performance is enhanced, and the air tightness detection of the lithium battery top cover is ensured to be accurate.

Embodiment 3

[0056] Example 3, see Figure 10-11 , the present embodiment is basically the same as Embodiment 1, the difference is that the upper chamber 16 and the lower chamber 15 are located on the outside of the lithium battery top cover detection placement groove, and are provided with an elastic pressure expansion sealing rubber ring 153, and a sealing Rubber ring groove 154, the elastic pressure expansion sealing rubber ring 153 is placed in the sealing rubber ring groove 154, the elastic pressure expansion sealing rubber ring 153 is provided with a hollow air passage 155, and the elastic pressure expansion sealing rubber ring is connected with an air compressor;

[0057] When the upper cavity and the lower cavity are pressed together, the air compressor presses air into the elastic pressure expansion sealing rubber ring, so that the elastic pressure expansion sealing rubber ring expands, and the elastic pressure expansion sealing rubber ring connects with the upper cavity and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com