Method for risk assessment and safety detection and evaluation of atmospheric pressure storage tanks

A technology of risk assessment and safety detection, applied in the direction of measuring devices, material analysis using acoustic wave emission technology, instruments, etc., can solve the problems of storage tank foundation bearing capacity decline, insufficient attention, groundwater pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

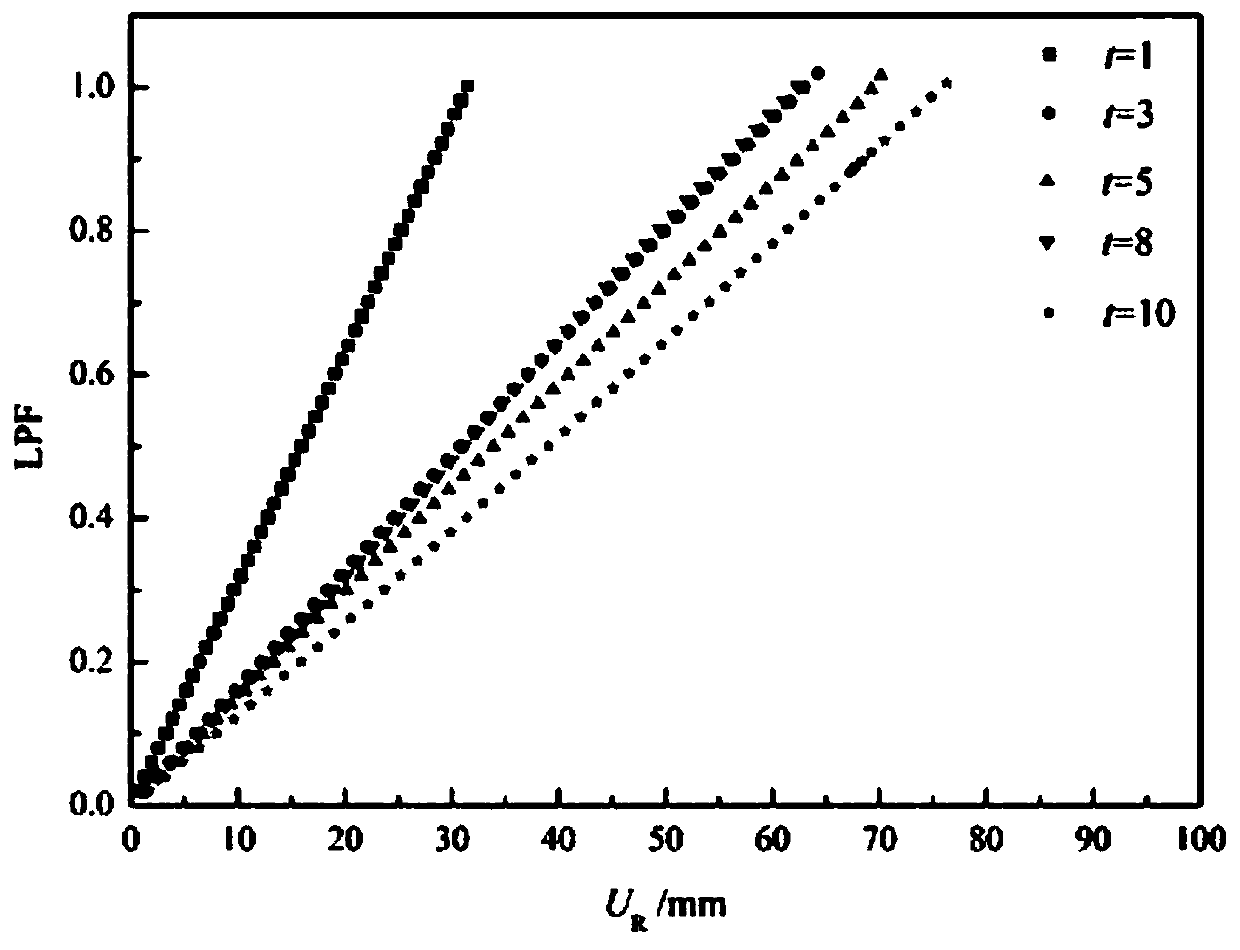

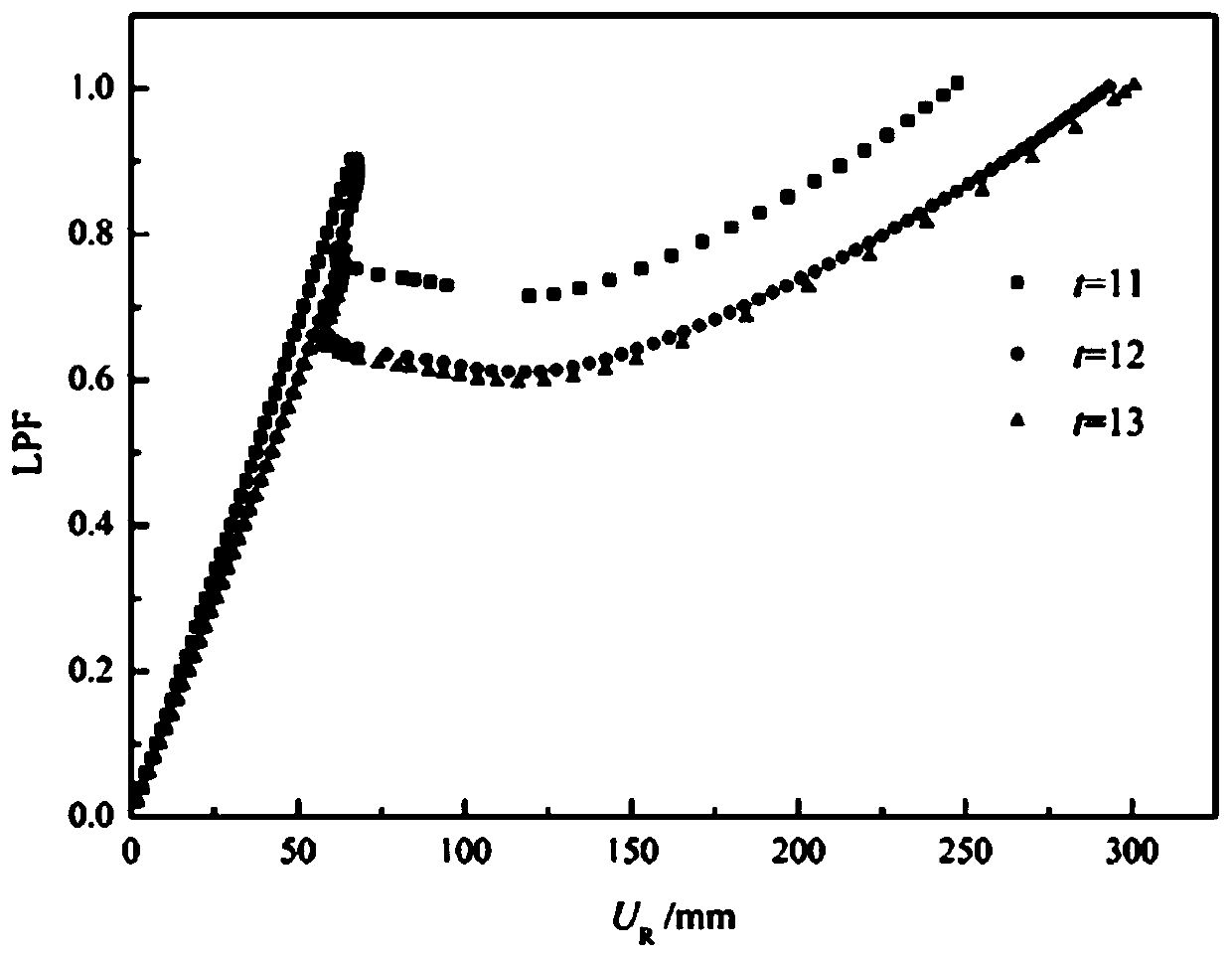

[0037] Such as Figure 1-5As shown, the present invention provides a safety detection and risk assessment method for atmospheric storage tanks, comprising the following steps: S1 screening storage tanks: collecting basic parameter information of all storage tanks, and performing RBI risk assessment for each storage tank; the RBI risk The assessed risk (R) is determined by the failure probability (F) and the failure consequence (C). LOF) is determined by the basic failure frequency (GFF) and the damage factor (DF). The basic failure frequency (GFF) can be obtained through the investigation and statistics of leakage failure events of a large number of storage tanks with different service life; the damage fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com