Crankshaft type vertical lifting mechanism and working method

A vertical lifting and crankshaft technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of equipment rollover, single chain structure prone to chain skipping, limited weight of fork pole goods, etc., and achieve fast cycle speed , compact structure, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

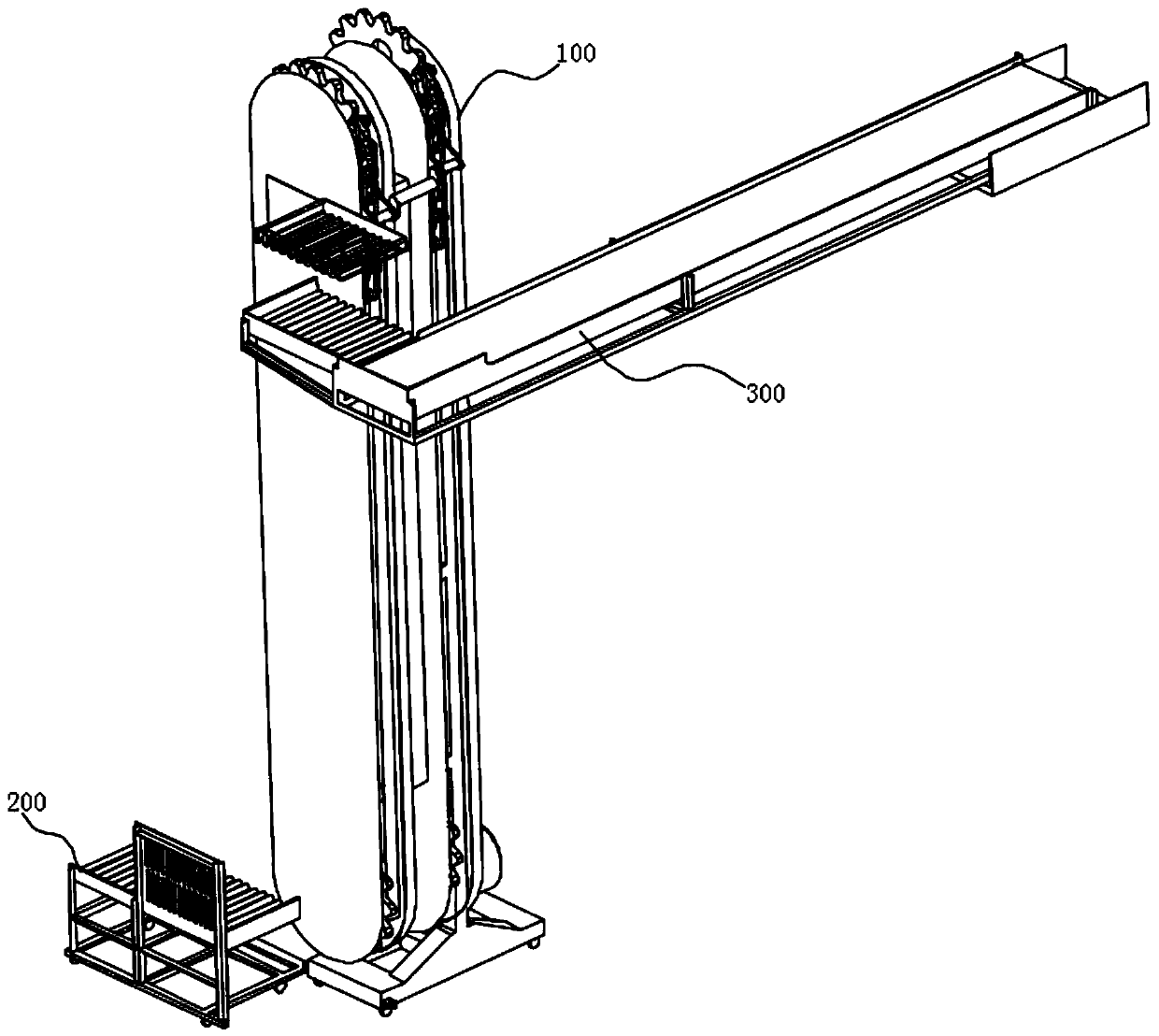

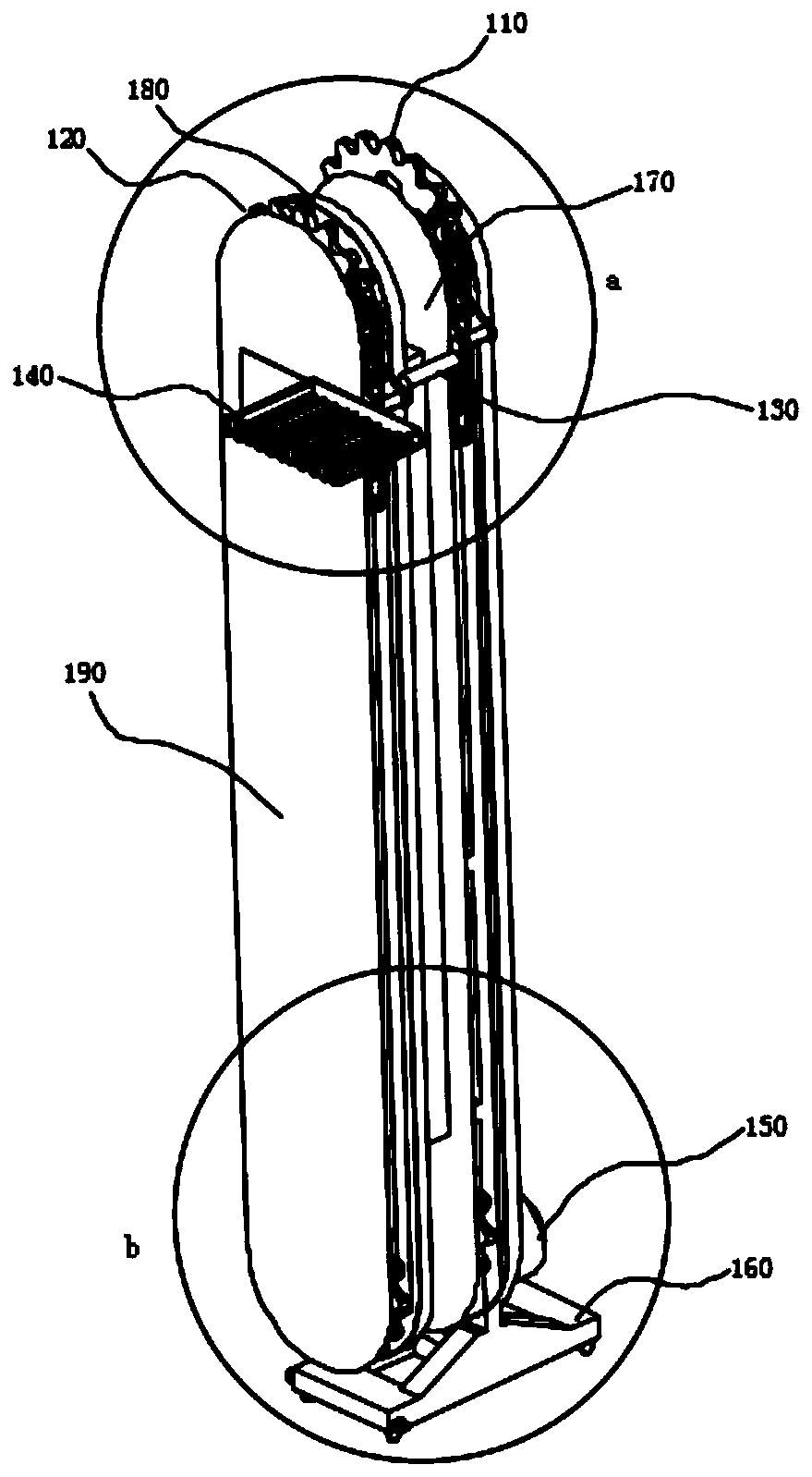

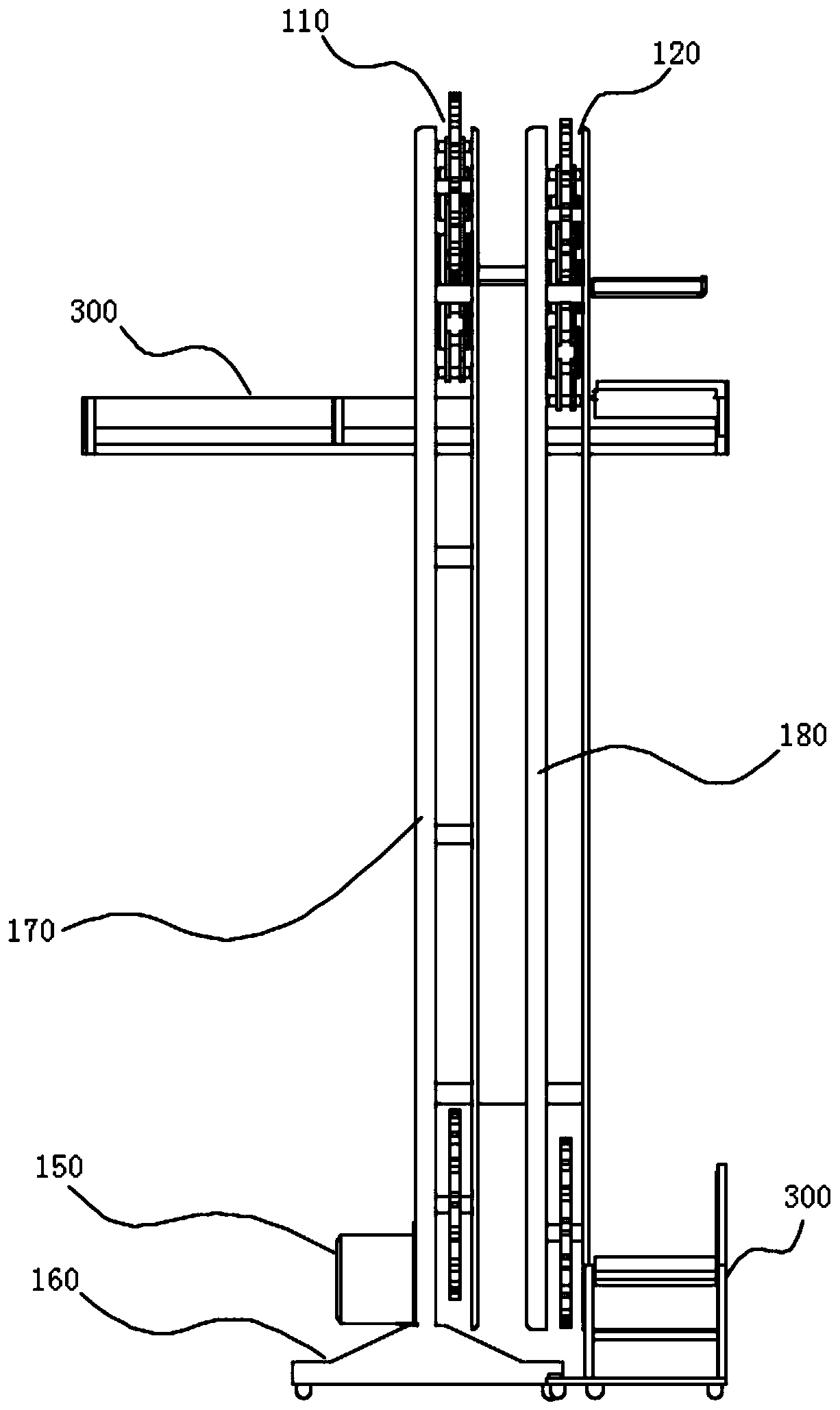

[0034] Such as Figure 1-5 As shown, a crankshaft-type vertical lifting mechanism includes a mechanism body 100 , a feeding and conveying device 200 and a material receiving and conveying device 300 . The mechanism body 100 comprises a driving sprocket device 110, a driven sprocket device 120, a crankshaft connecting device 130, a claw bar 140, a drive motor 150 and a base 160; the base 160 is provided with a driving frame 170 and a driven frame 180, and the driving frame 170 Equal to the driven frame height 180, the driving frame 170 is connected with the driven frame 180, and the driving frame 170 and the driven frame 180 are respectively provided with two gear connecting rods, and the gear connecting rods on the driving frame 170 are higher than the driven frame 180 The gear connecting rod on the top, the driving sprocket device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com