A method for preparing patterned transparent conductive film by laser

A transparent conductive film and patterning technology, which is applied in the direction of equipment, circuits, and electrical components used to manufacture conductive/semiconductive layers, can solve the problems of limiting film light transmittance, lack of flexibility, etc., and achieve fast, High flexibility and high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

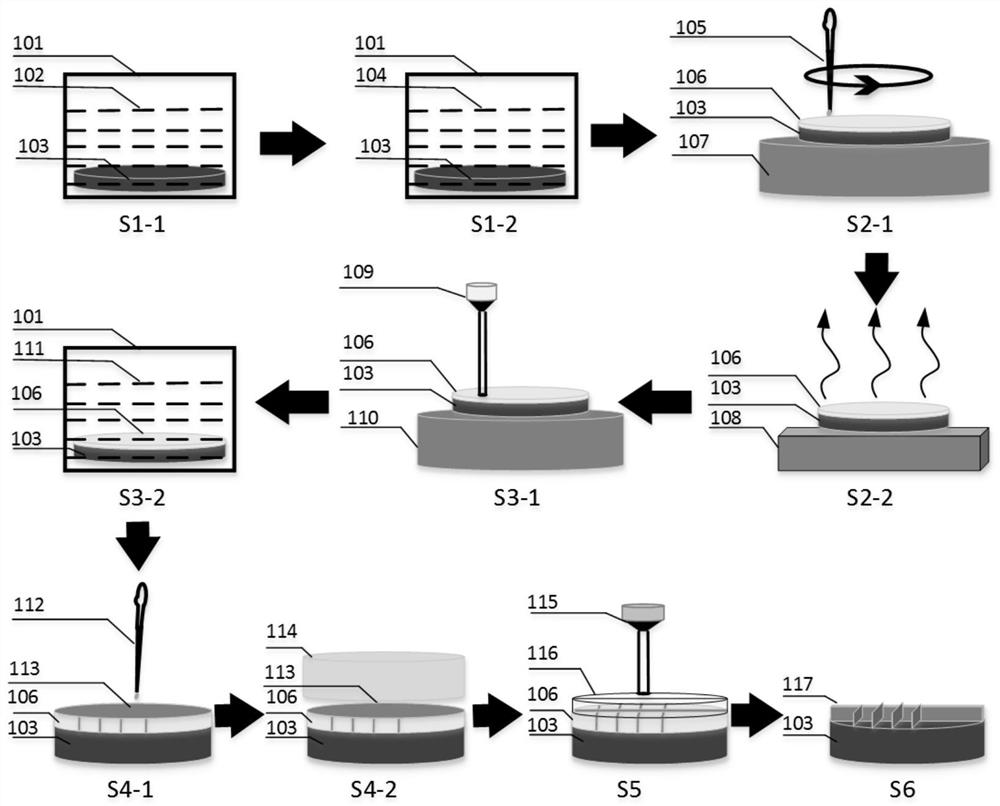

[0037] Such as figure 1 As shown, the method for preparing a patterned transparent conductive film by laser provided in the first embodiment specifically includes the following steps:

[0038] S1-1. Add 100ml of acetone solution 102 into a 500ml beaker 101, then clamp a 2-inch Sapphire substrate 103 into the beaker 101 with tweezers, and clean the organic impurities on the surface of the Sapphire substrate 103;

[0039] S1-2. Pour off the acetone solution 102, add absolute ethanol (99.7wt.%) 104, also clamp the Sapphire substrate 103 into the beaker with tweezers, and clean the remaining acetone solution 102 on the surface of the substrate;

[0040] S2-1. After cleaning and drying the substrate 103, place it on the spin coater 107, drop a few drops of photoresist on the substrate 103 with the first dropper 105, then turn on the spin coater 107 and start to rotate, set The rotation speed is 4000rpm, the rotation time is 30s, and the photoresist coating 106 is obtained; (the ph...

Embodiment 2

[0049] Such as figure 1As shown, the method for preparing a patterned transparent conductive film by laser provided in the first embodiment specifically includes the following steps:

[0050] S1-1. Add 100ml of acetone solution 102 into a 500ml beaker 101, then clamp a 2-inch Sapphire substrate 103 into the beaker 101 with tweezers, and clean the organic impurities on the surface of the Sapphire substrate 103;

[0051] S1-2. Pour off the acetone solution 102, add absolute ethanol (99.7wt.%) 104, also clamp the Sapphire substrate 103 into the beaker with tweezers, and clean the remaining acetone solution 102 on the surface of the substrate;

[0052] S2-1. After cleaning and drying the substrate 103, place it on the spin coater 107, drop a few drops of photoresist on the substrate 103 with the first dropper 105, then turn on the spin coater 107 and start to rotate, set The rotation speed is 6000rpm, the rotation time is 20s, and the photoresist coating 106 is obtained; (the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com