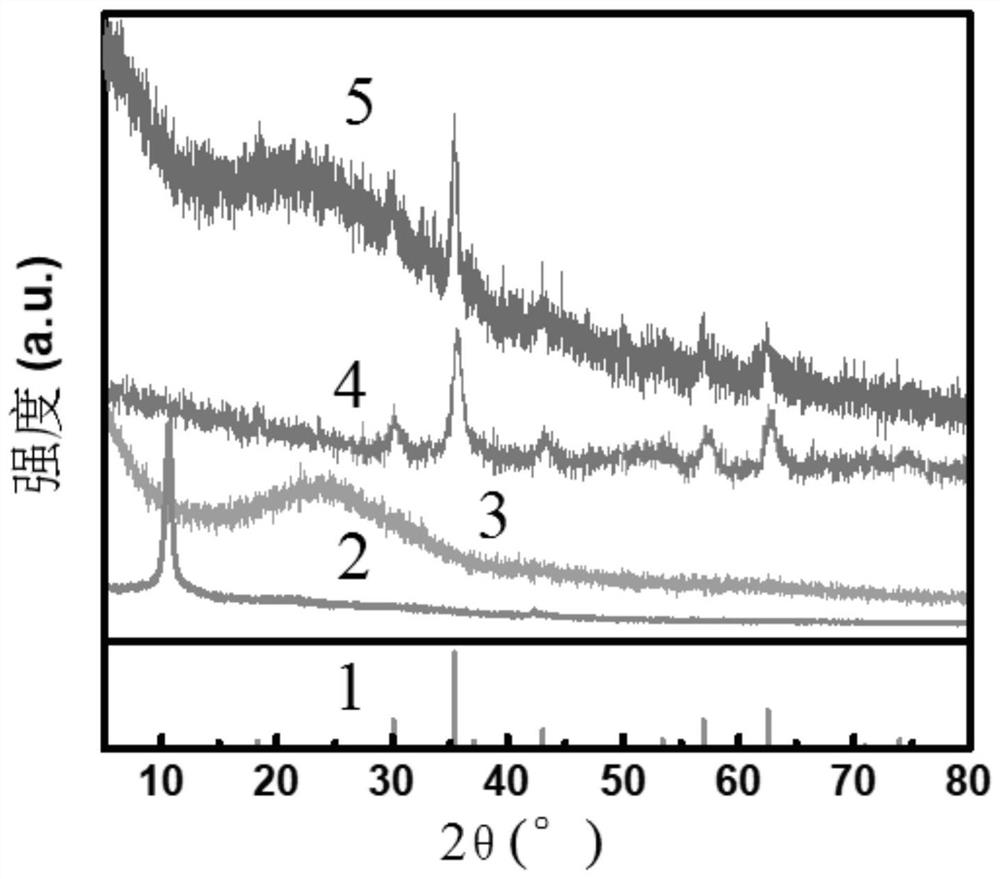

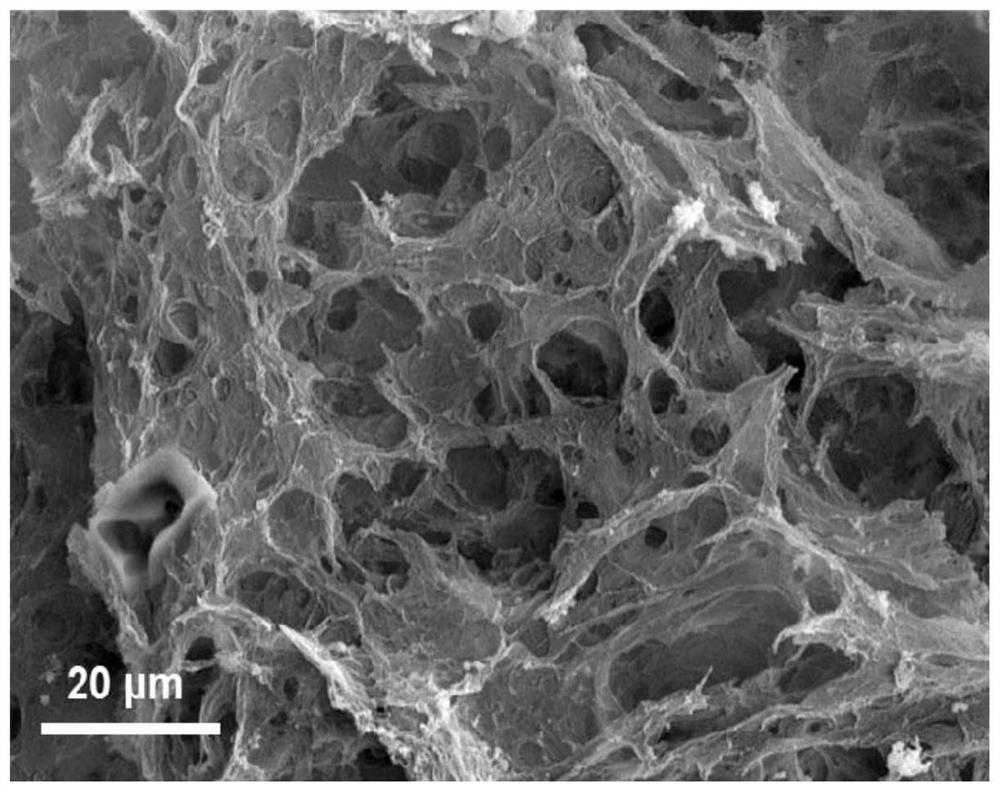

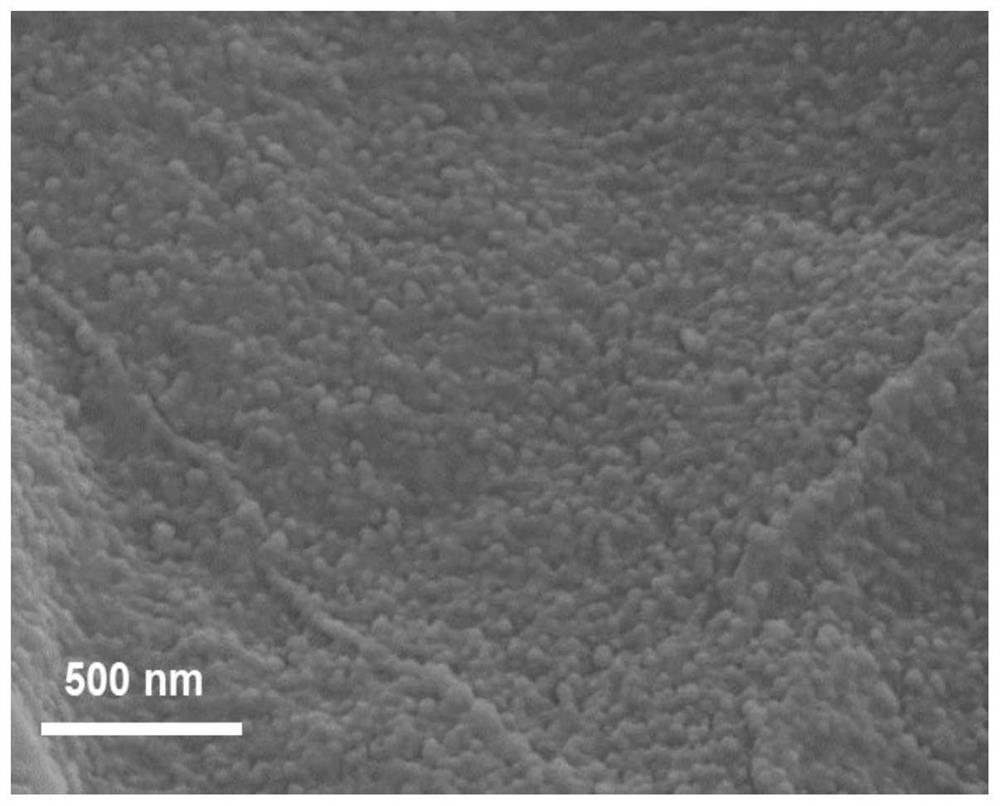

A kind of preparation method of ultra-small ferric oxide densely coated three-dimensional reduced graphene oxide-based Fenton catalyst

A technology of ultra-small ferroferric oxide and graphene, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of weak catalytic active sites, Inhomogeneity and other problems, to achieve the effect of accelerating the interface electron transfer rate, small iron dissolution, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment 1: This embodiment is a preparation method of ultra-small ferric oxide densely coated three-dimensional reduced graphene oxide-based Fenton catalyst, which is completed according to the following steps:

[0037] 1. Preparation of graphene oxide dispersion:

[0038] The graphene oxide is added to deionized water, and then ultrasonically treated to obtain a graphene oxide dispersion;

[0039] The concentration of the graphene oxide dispersion described in step 1 is 0.5mg / mL~2mg / mL;

[0040] Second, the FeCl 3·6H 2 O joins in the graphene oxide dispersion liquid, stirs again, obtains solution I;

[0041] FeCl described in step 2 3 ·6H 2 The mass ratio of O to the volume of graphene oxide dispersion is (0.4g~0.8g): 30mL;

[0042] 3. Use NaHCO 3 Adjust the pH value of solution I to 8-12, and then stir to obtain solution I with pH value of 8-12;

[0043] 4. Add the ascorbic acid solution dropwise to the solution I with a pH value of 8 to 12 under s...

specific Embodiment approach 2

[0056] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the power of the ultrasonic treatment in step 1 is 100W-150W, and the ultrasonic treatment time is 1h-3h. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stirring time described in step 2 is 20 min to 40 min, and the stirring speed is 800 r / min to 1000 r / min. Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com