A Repairing Technology for Locomotive Bogie Frame Deformation

A frame and locomotive technology, which is applied in the field of repairing process of deformation of locomotive bogie frame, can solve problems such as affecting the company's economic benefits and waste of locomotive product manufacturing costs, and achieve stable and reliable repair quality, improvement of repair technology and improvement of repair level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

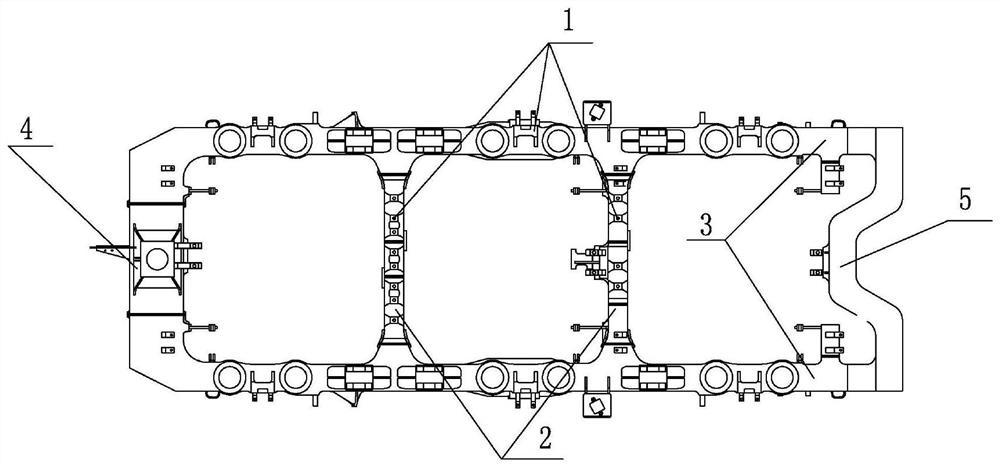

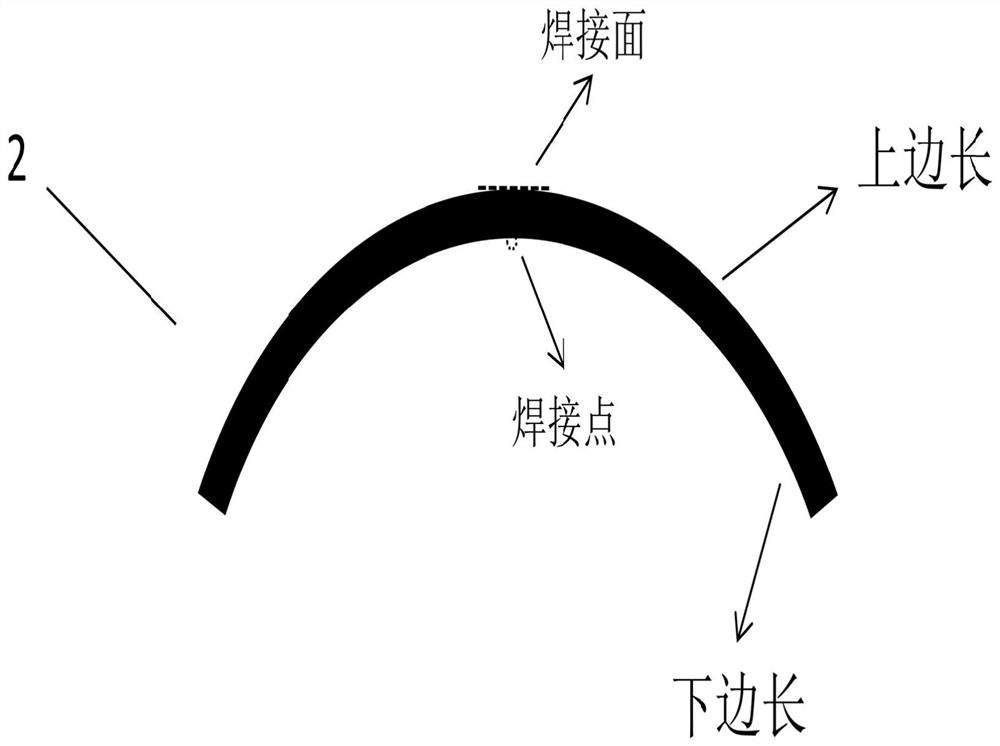

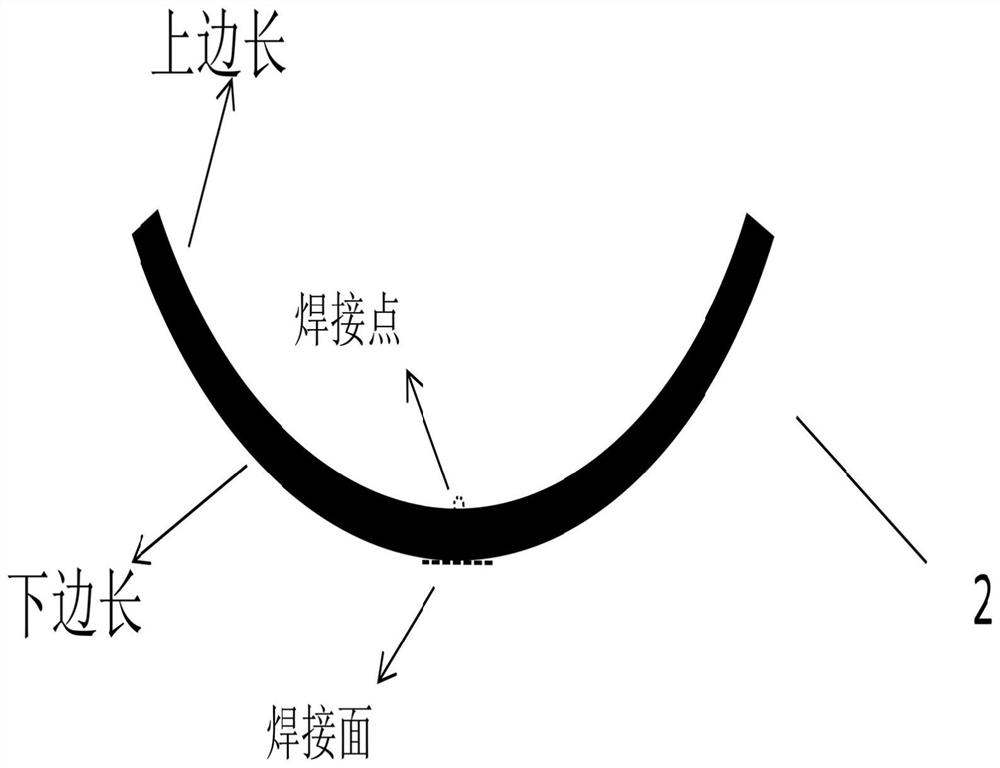

[0047] Usually a locomotive bogie frame consists of 2 beams 2, 2 side beams 3, 1 traction beam 4, 1 front end beam 5 and several steel castings 1, figure 1 It is a structural diagram of the locomotive bogie frame.

[0048] The repairing process for the deformation of the locomotive bogie frame includes the following steps:

[0049] After sanding and cleaning the deformed (unqualified) frame, place it on a three-coordinate inspection machine for inspection, scribing, and detection of out-of-tolerance positions and incomplete parts; use a three-coordinate measuring machine to accurately detect the deviation value of the frame deformation and defect conditions, providing reliable adjustment data for resto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com