Shot blasting device for vertical face transverse treatment

A technology of lateral processing and shot blasting device, which is applied to used abrasive processing devices, abrasives, metal processing equipment, etc. Save space and increase working height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

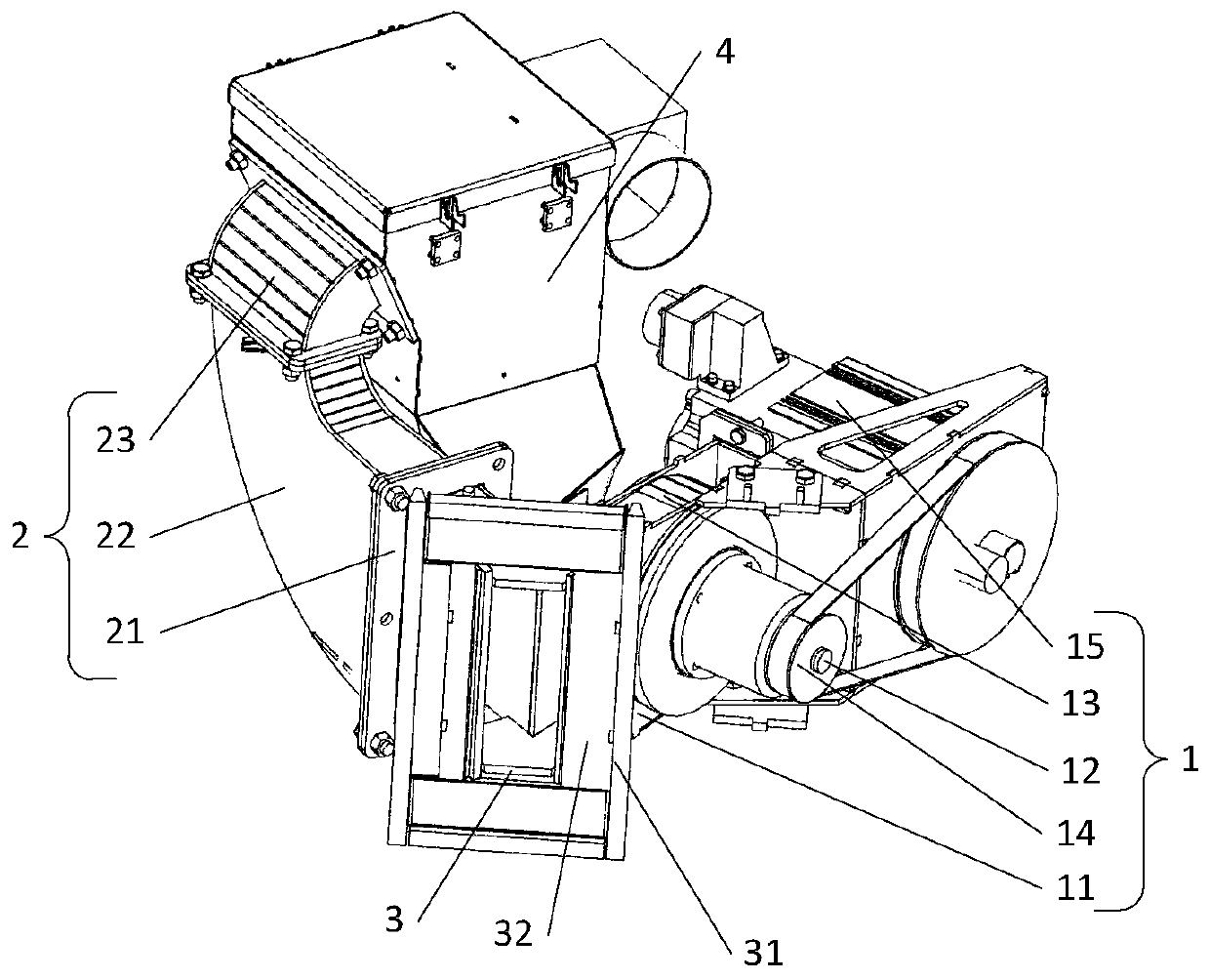

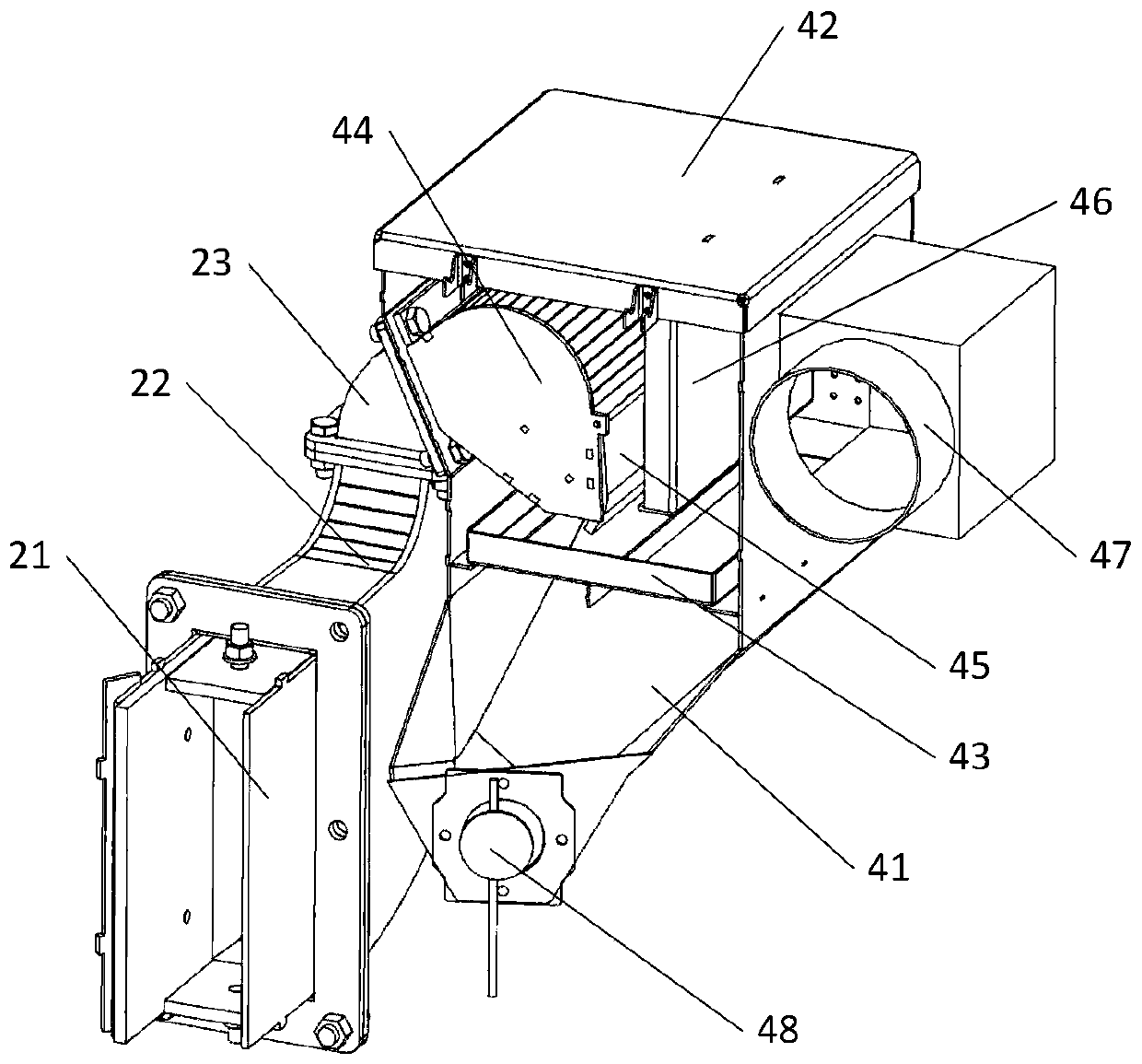

[0029] like Figure 1 ~ Figure 3 As shown, the shot blasting device for vertical horizontal treatment provided in this embodiment includes a shot blasting mechanism 1 , a feeding mechanism 2 and a separation mechanism 4 .

[0030] The shot blasting mechanism 1 is placed under the separation mechanism 4. The shot blasting mechanism 1 includes an impact bin 11, a shot blasting wheel 13 and a motor 15. The shot blasting wheel 13 is rotatably installed inside the impact bin 11 through a rotating shaft 12. One end of the rotating shaft 12 passes through the impact chamber 11 and is connected with a transmission wheel 14. A motor 15 that can drive the transmission wheel 14 to rotate is also installed on the outer wall of the impact chamber 11. The transmission wheel 14 can be a pulley, a sprocket, etc.

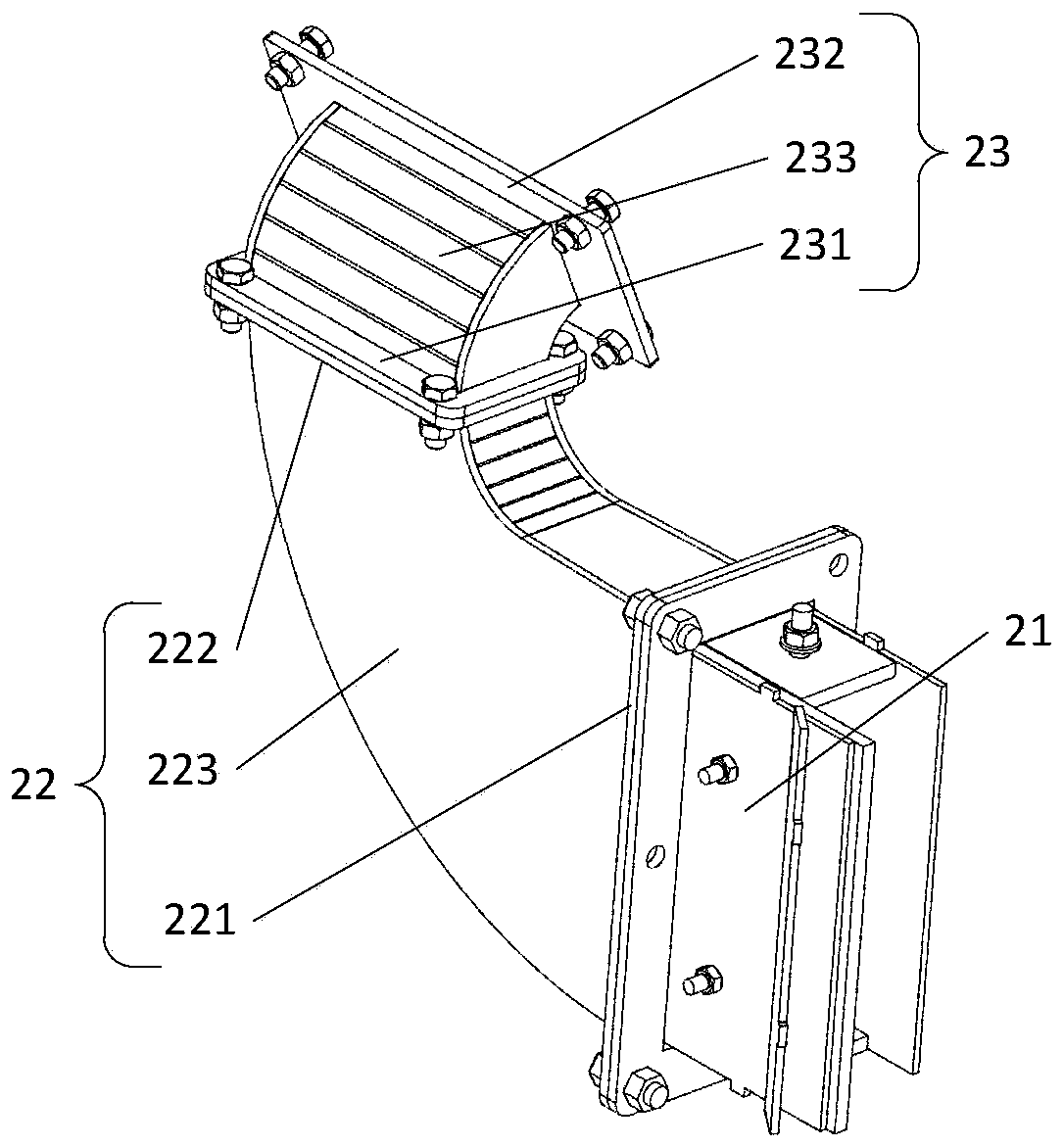

[0031] The material return mechanism 2 includes a direct current section 21, an arc-shaped lifting section 22 and an arc-shaped turning section 23, and the direct-flow section 21, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap